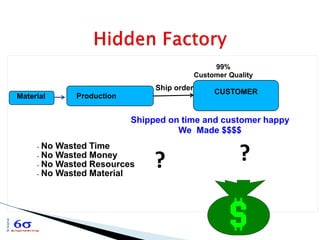

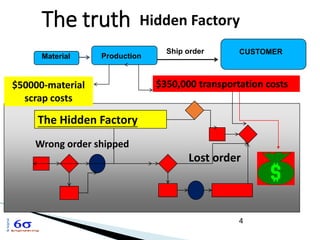

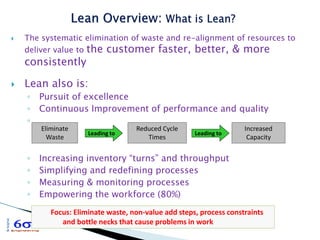

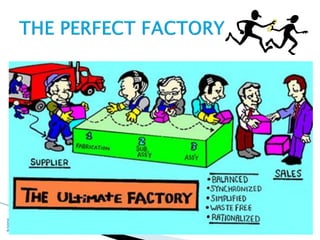

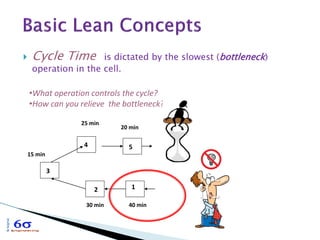

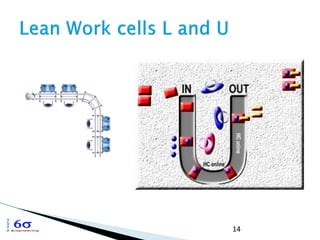

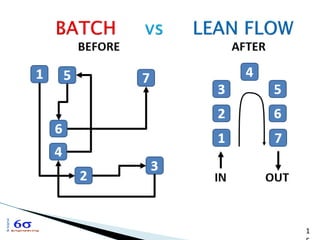

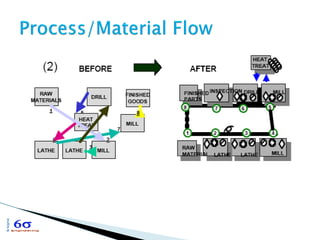

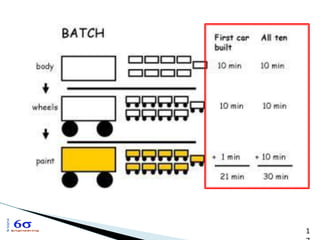

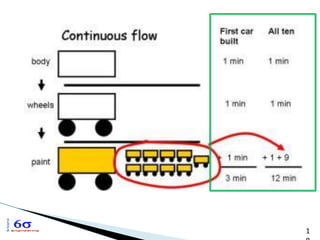

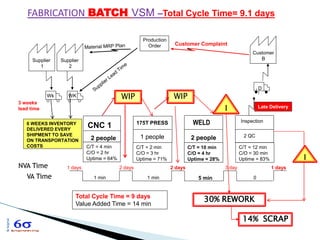

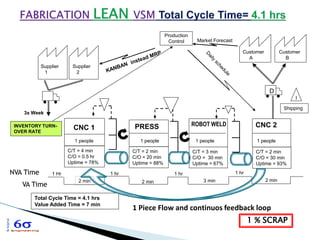

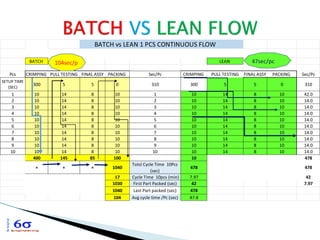

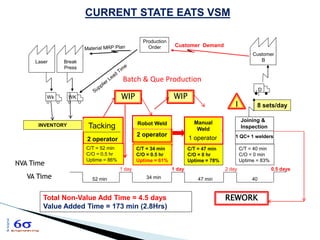

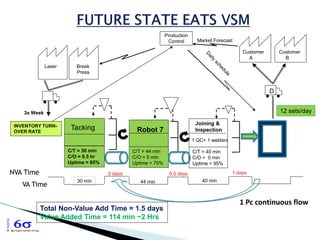

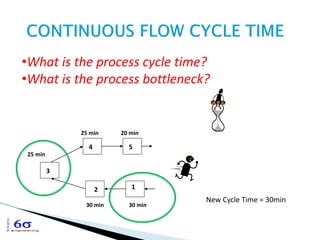

The document compares and contrasts continuous flow and batch production methods. Continuous flow focuses on eliminating waste such as waiting time, excess inventory, and defects through one-piece flow and small batch sizes. This allows for faster cycle times, increased throughput and capacity, and reduced lead times compared to batch production which typically has longer cycle times and more non-value added time due to large batch sizes and waiting between processes. The document provides examples of value stream maps to illustrate the differences between batch and continuous flow production systems.