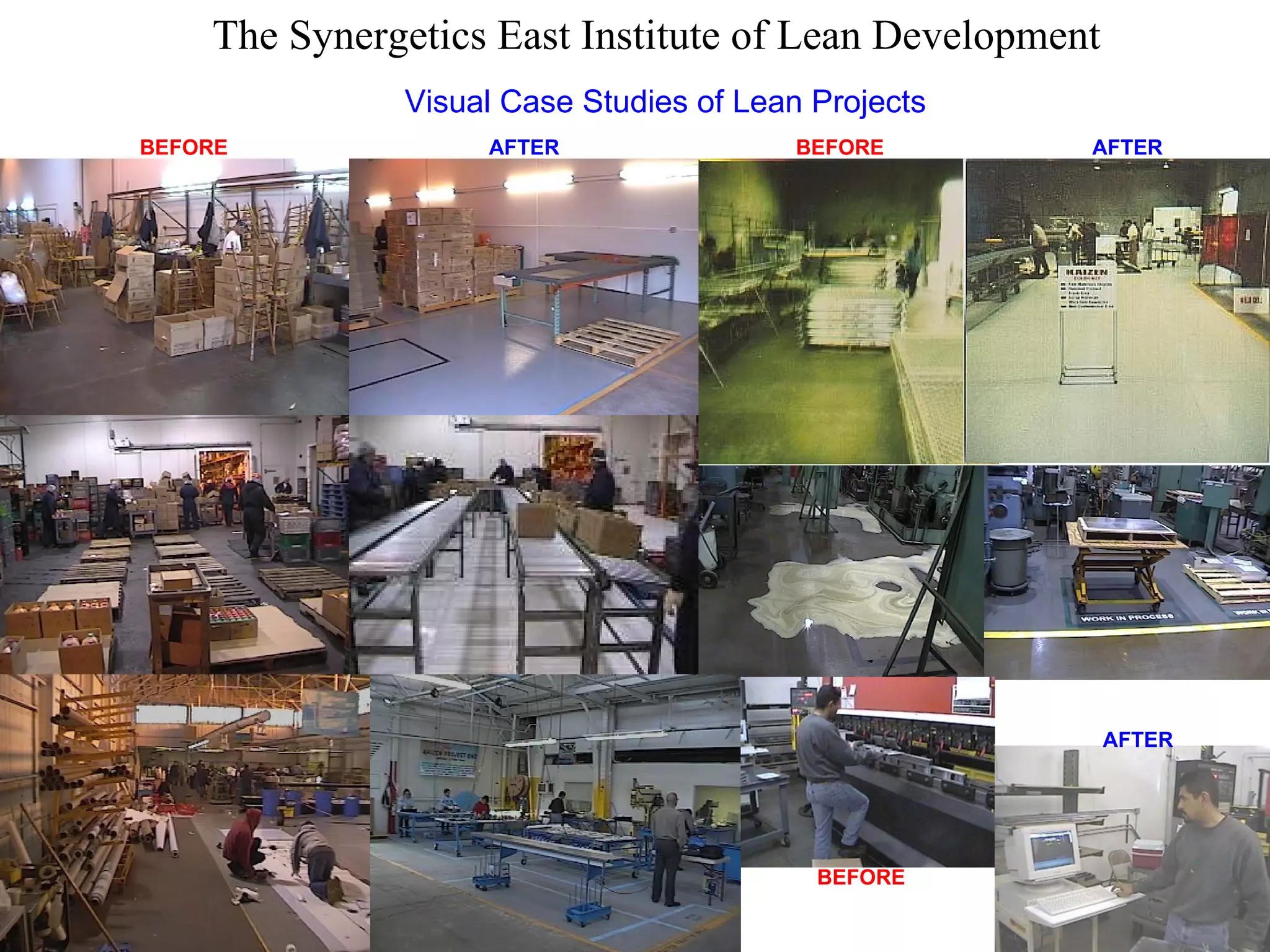

The document describes several case studies of companies that implemented lean principles to improve their operations:

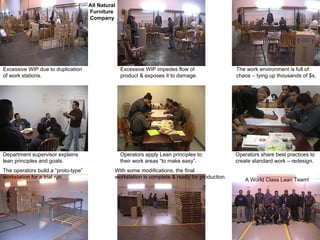

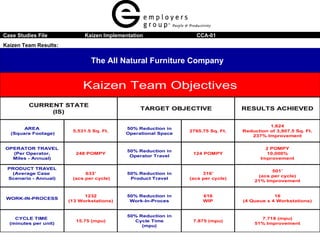

1. The All Natural Furniture Company eliminated duplication of work stations, reducing waste in process (WIP) and allowing smoother product flow with less risk of damage.

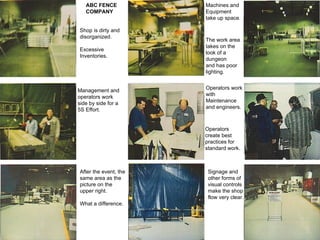

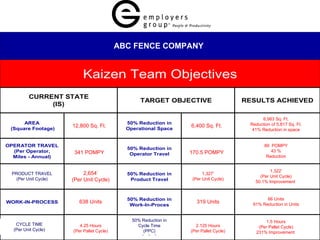

2. ABC Fence Company reduced their facility space by 41% and cut production time by 50% through applying 5S and standard work practices.

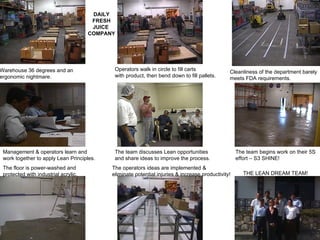

3. The Daily Fresh Juice Company improved ergonomics and cleanliness in their warehouse by implementing operator ideas from lean training.

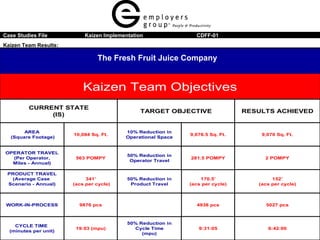

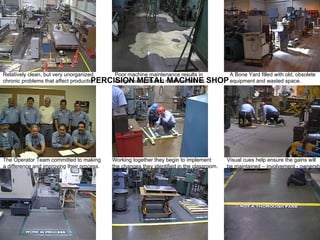

4. Multiple other companies saw improvements such as reduced space usage, lead times, inventory levels and defects by applying lean tools with cross-functional teams.