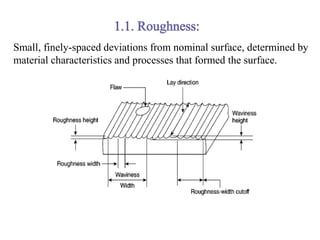

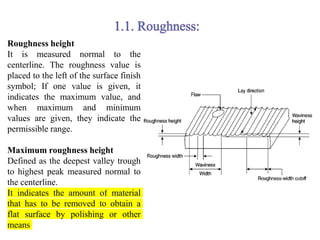

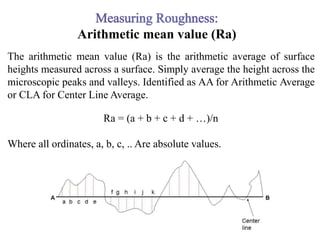

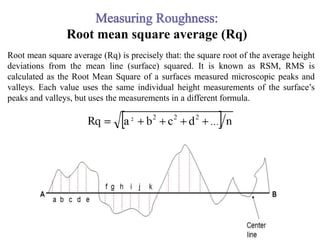

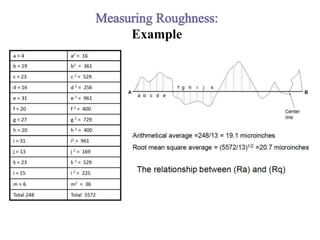

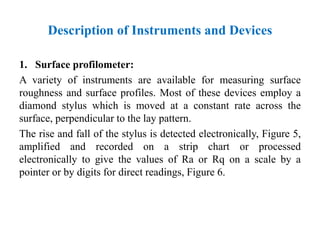

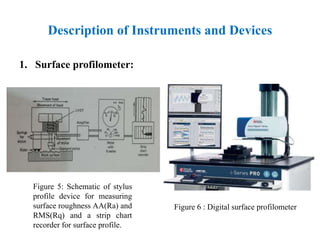

1. The document discusses surface profilometry and surface roughness. It defines terms like arithmetic mean roughness (Ra), root mean square roughness (Rq), and describes instruments used to measure surface roughness like surface profilometers and surface roughness standards.

2. Surface profilometers use a diamond stylus to detect deviations from a surface which are amplified and recorded to determine values of Ra and Rq. Digital profilometers directly display these values.

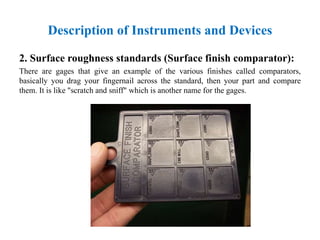

3. Surface roughness standards are used for comparison by dragging a fingernail across them and the test surface.