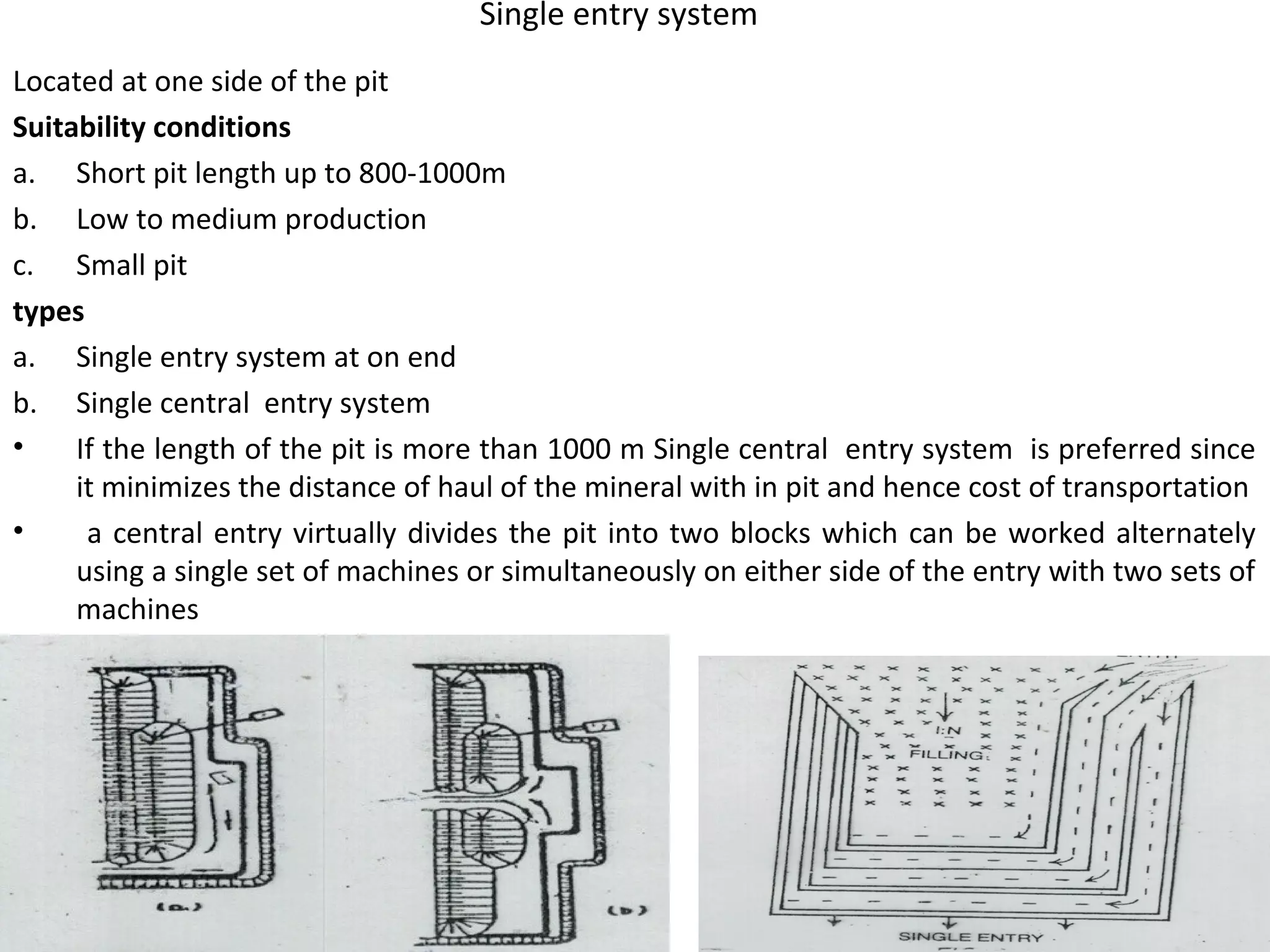

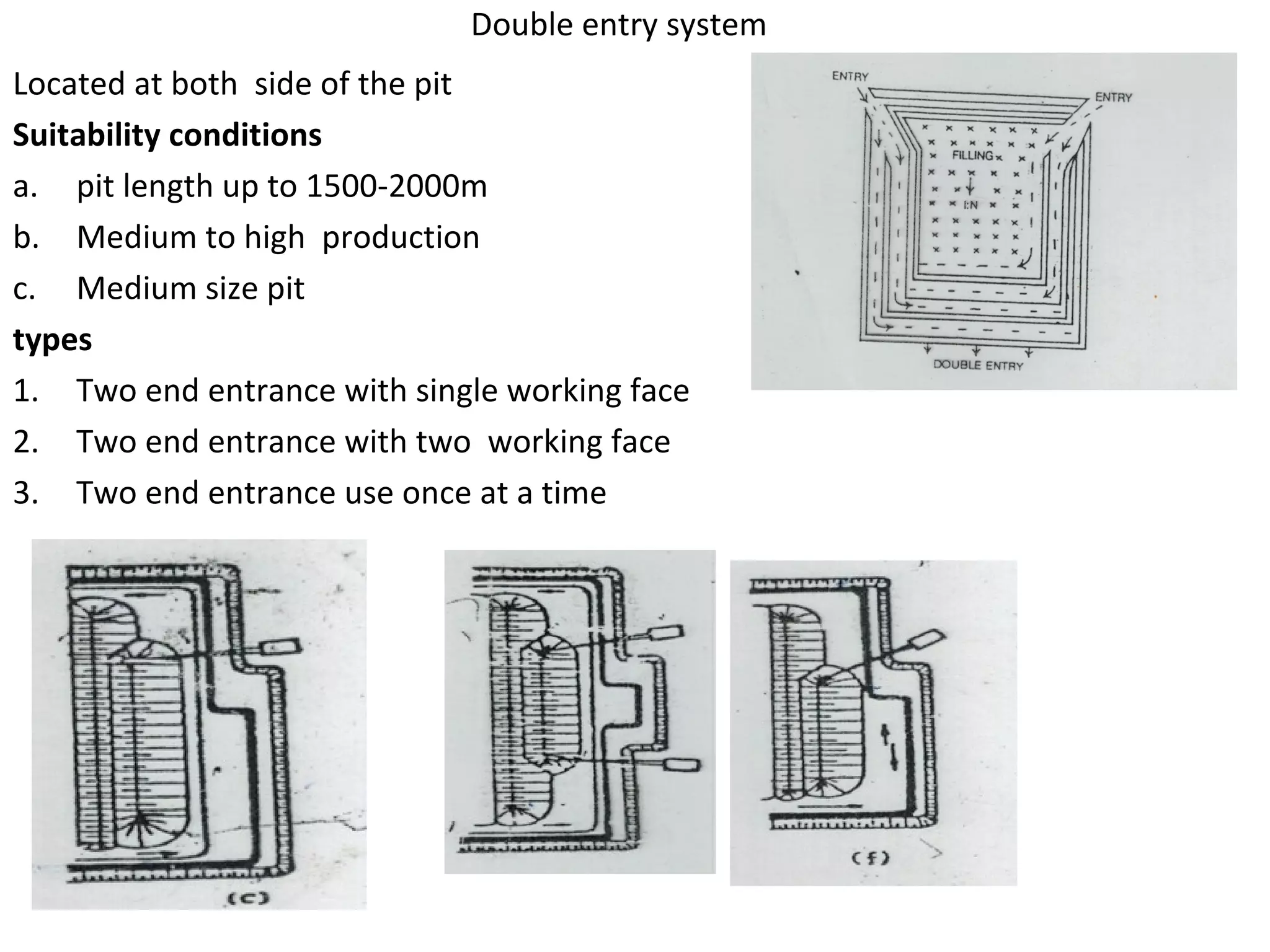

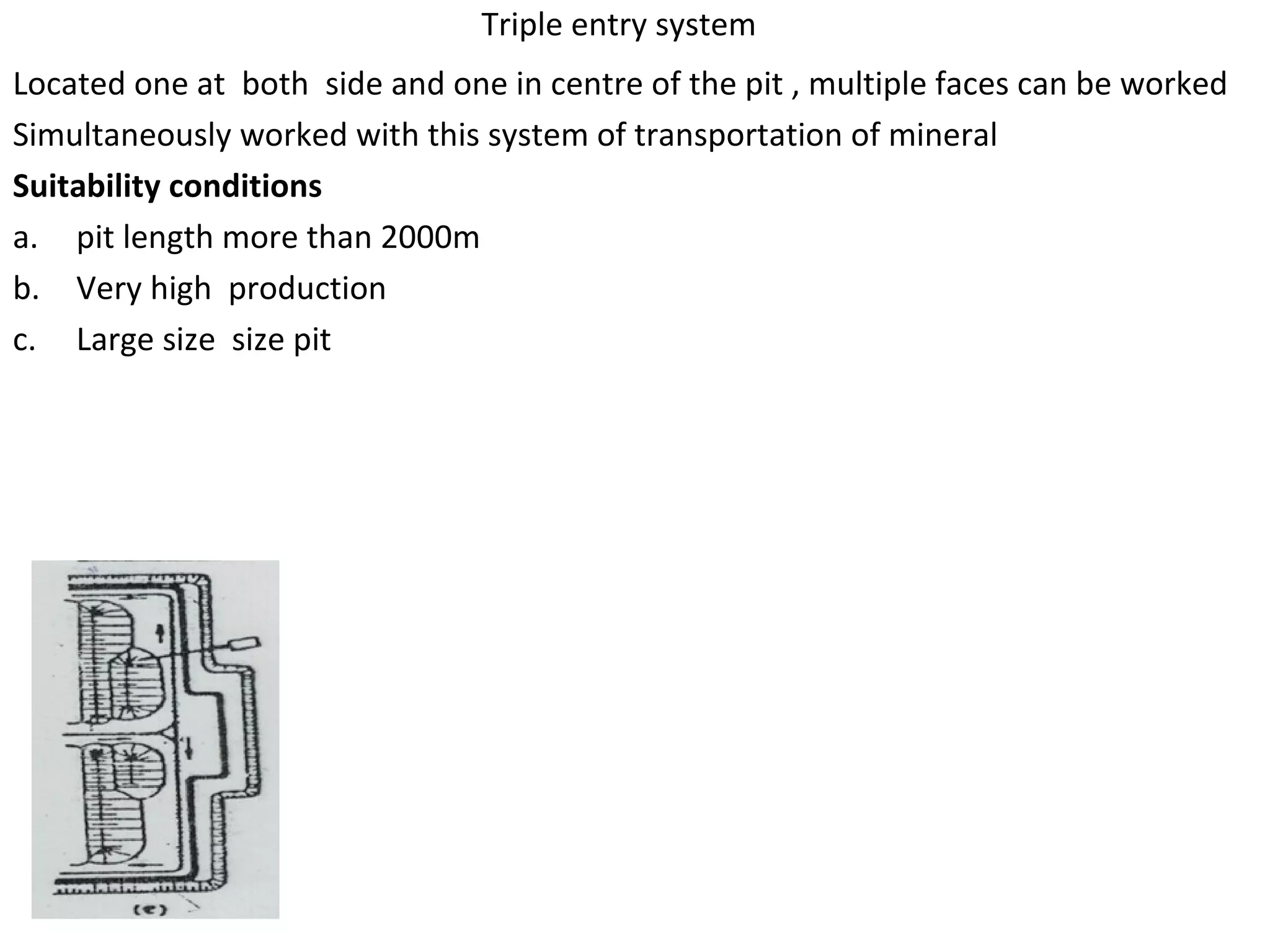

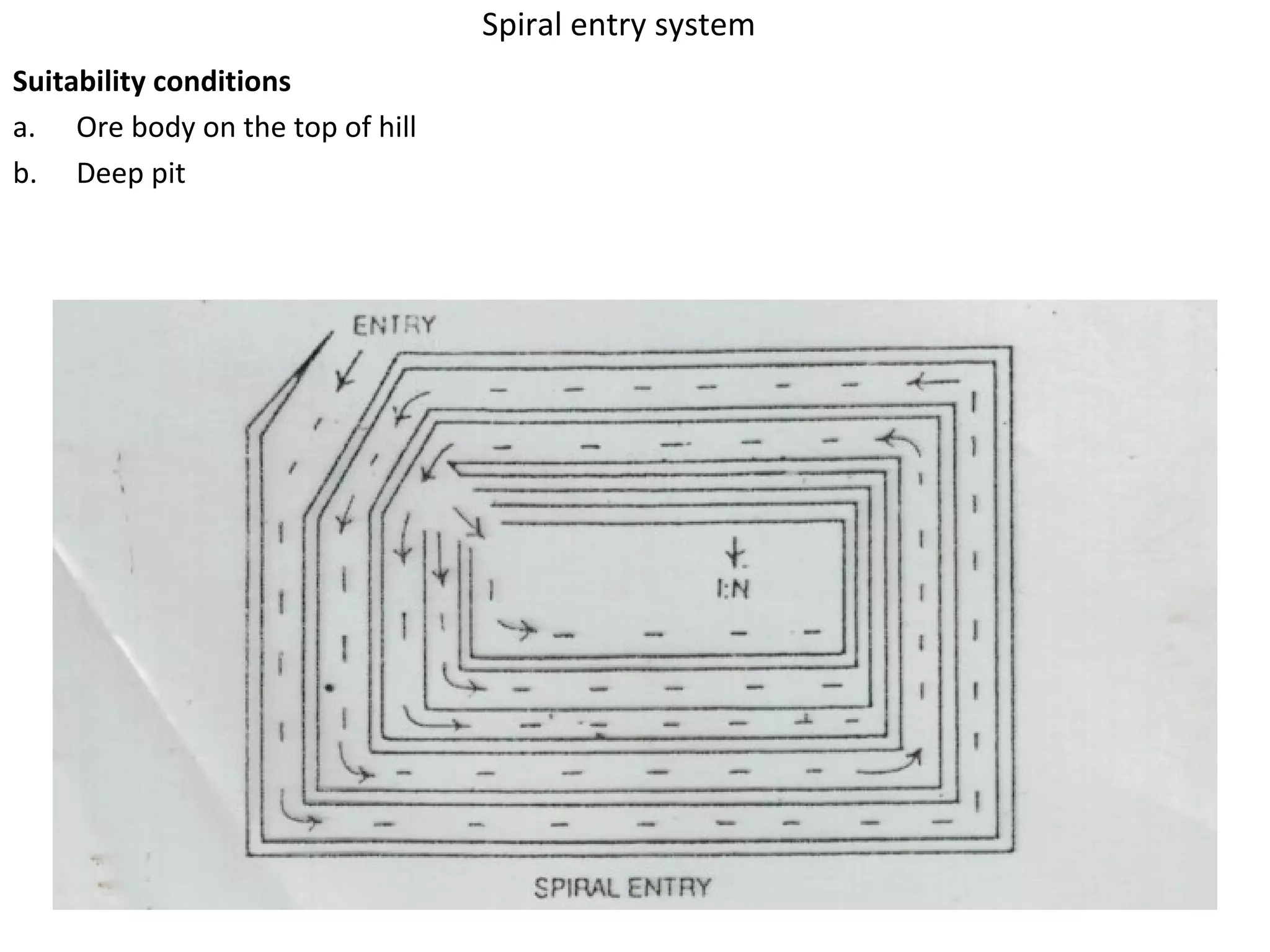

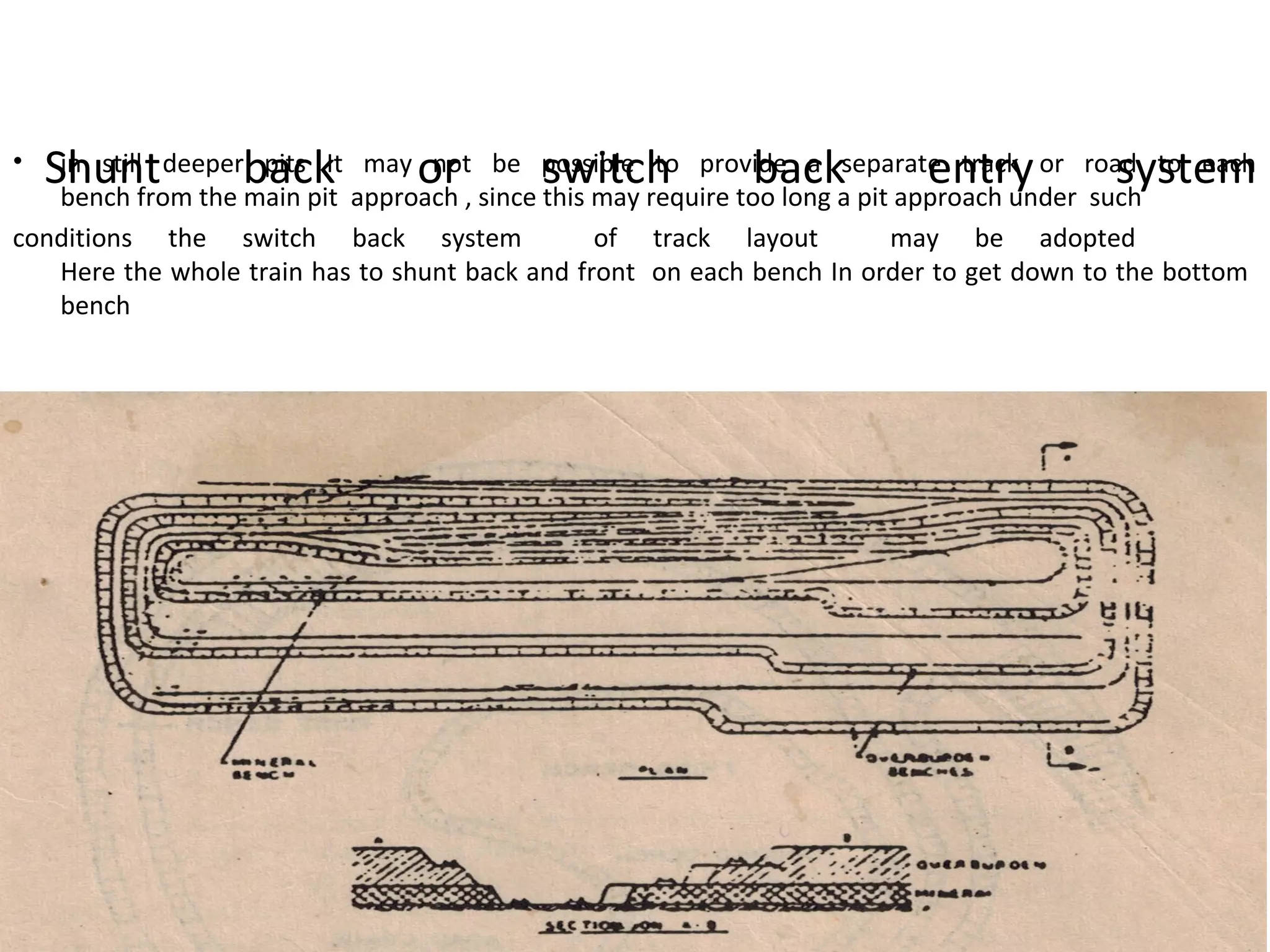

This document discusses different types of entry systems used in opencast mines. It describes single, double, triple, and spiral entry systems. Single entry systems are suitable for short pits up to 1000m with low production. Double entry systems are used for pits up to 1500-2000m with medium production. Triple entry systems have entries on both sides and in the center for large, high production pits over 2000m. Spiral entry systems are used for pits on hilltops or deep pits. The appropriate type of entry system depends on factors like pit length, production levels, transportation needs, and overall economics.