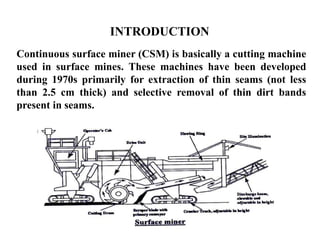

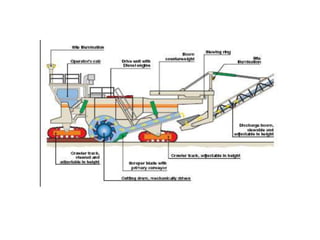

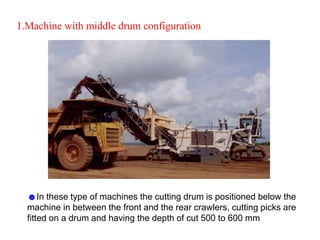

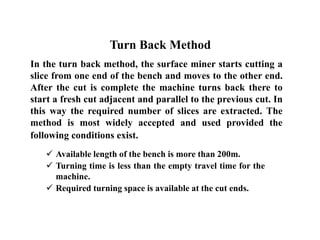

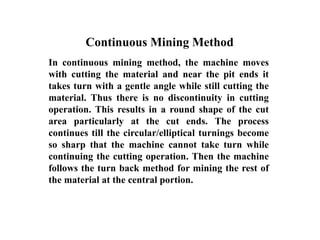

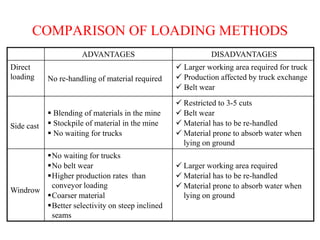

The document discusses continuous surface miners (CSM), which are cutting machines used in surface mines to extract thin seams less than 2.5 cm thick. It provides details on the key components of CSMs including the mainframe, conveying unit, drive unit, crawler unit, and cutting unit. It also describes different methods of working with CSMs based on the sequence of strip extraction, travel mode, and loading mode. CSMs can extract material continuously while crushing and directly loading it onto trucks, providing an environmentally-friendly alternative to conventional drilling, blasting, and loading methods.