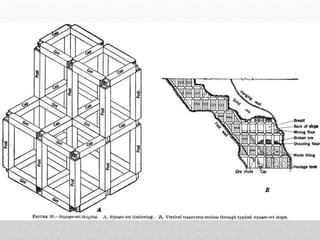

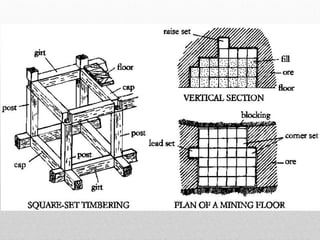

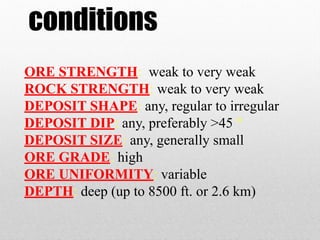

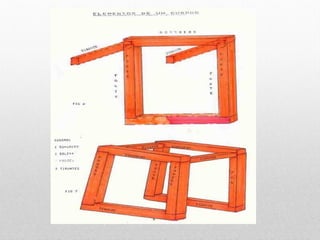

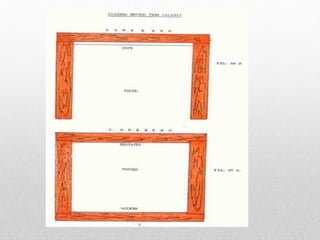

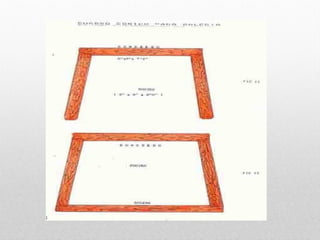

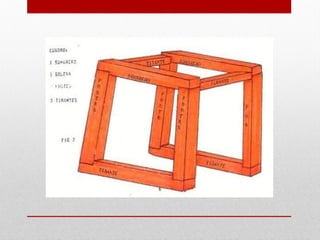

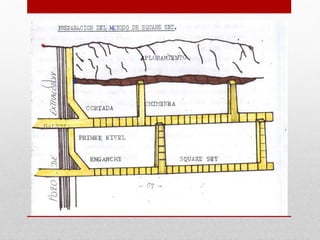

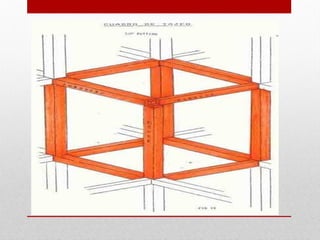

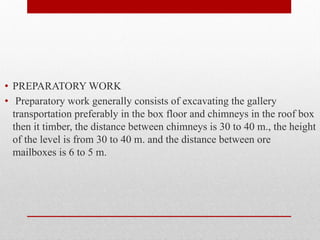

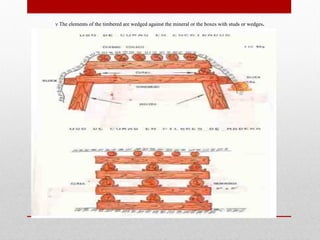

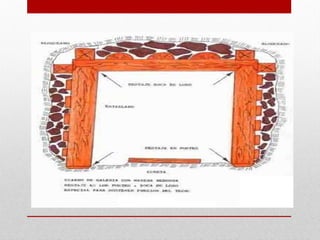

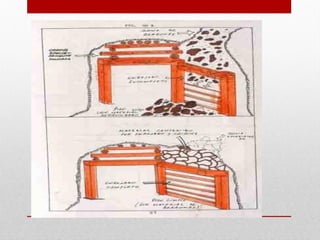

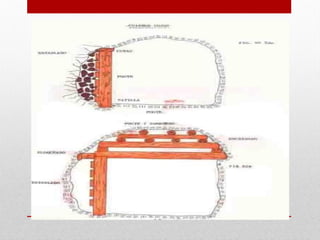

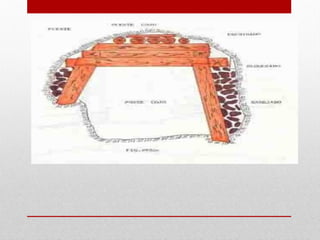

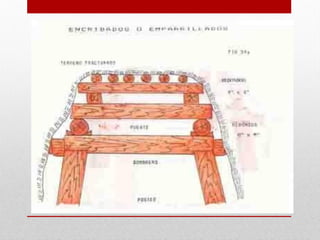

Square-set stoping is an underground mining method that relies on timber frames called "sets" for ground support. It involves removing small blocks of ore and immediately replacing them with pre-built timber sets that are interlocked. The space between the sets is then filled with waste rock or sand. It allows for selective mining of irregular deposits with minimal dilution. However, it has very low productivity and high costs due to the extensive timbering required and is labor intensive. Square-set stoping is best suited for deposits that are too narrow, irregular or unstable for other methods.