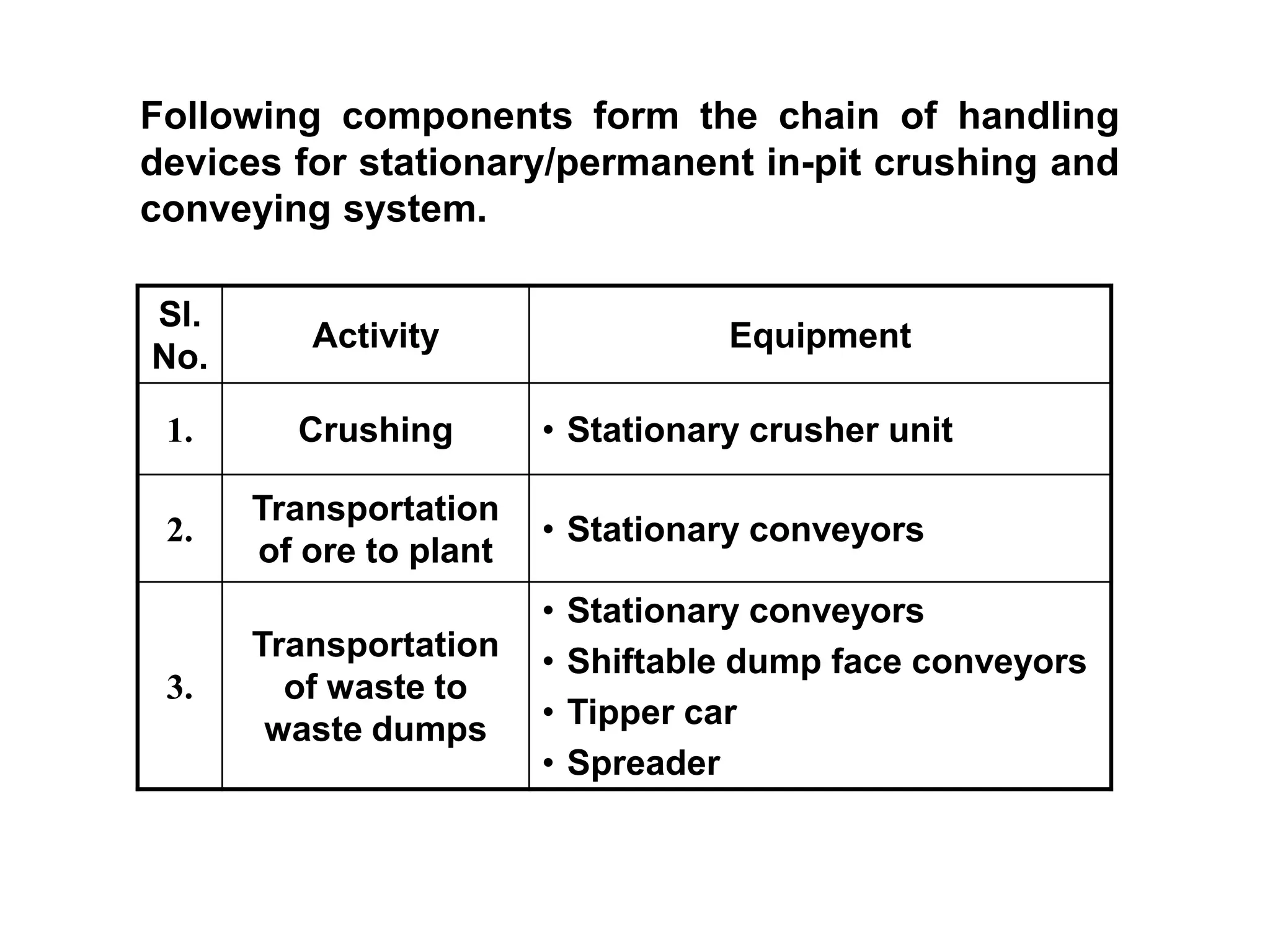

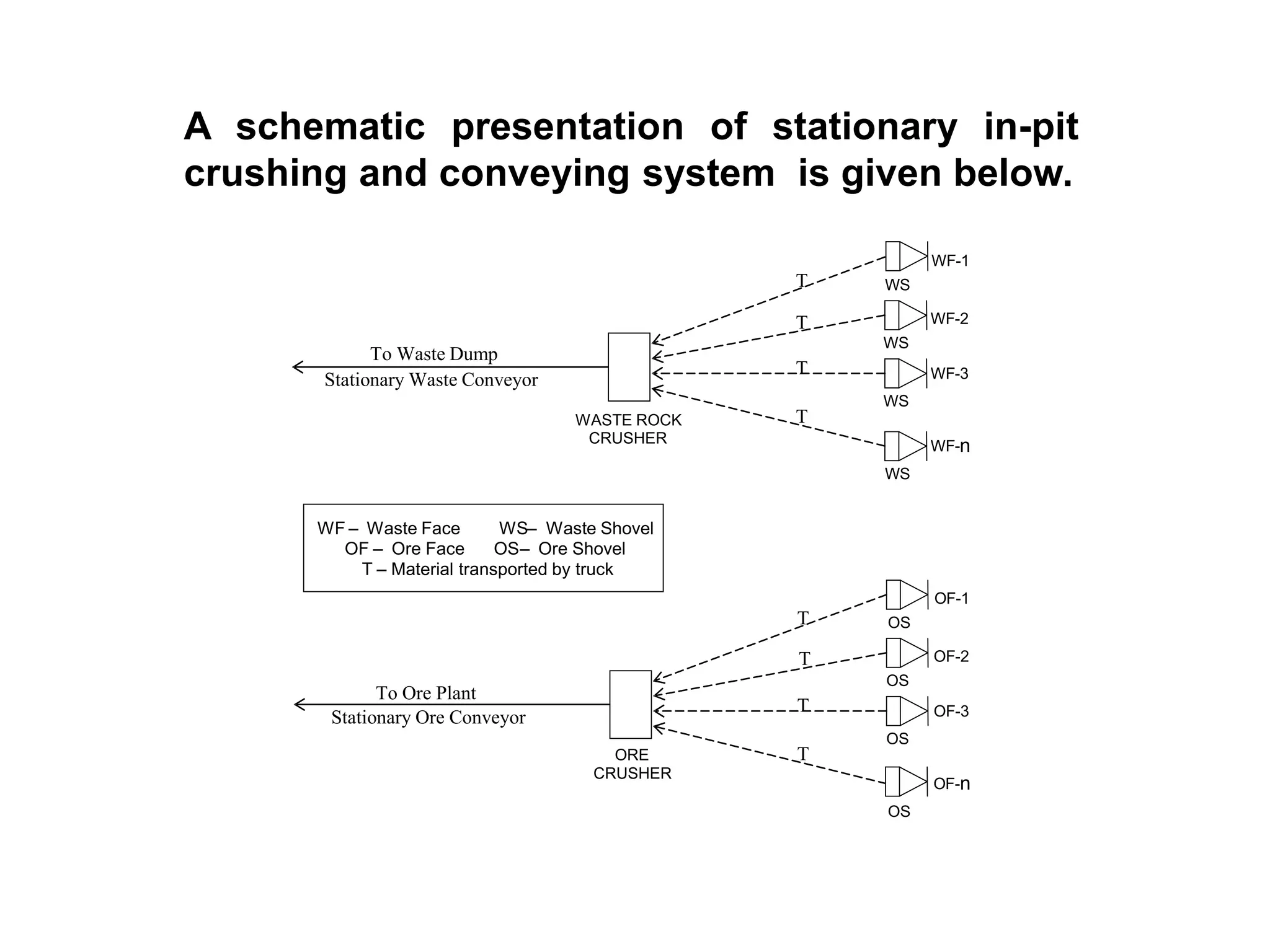

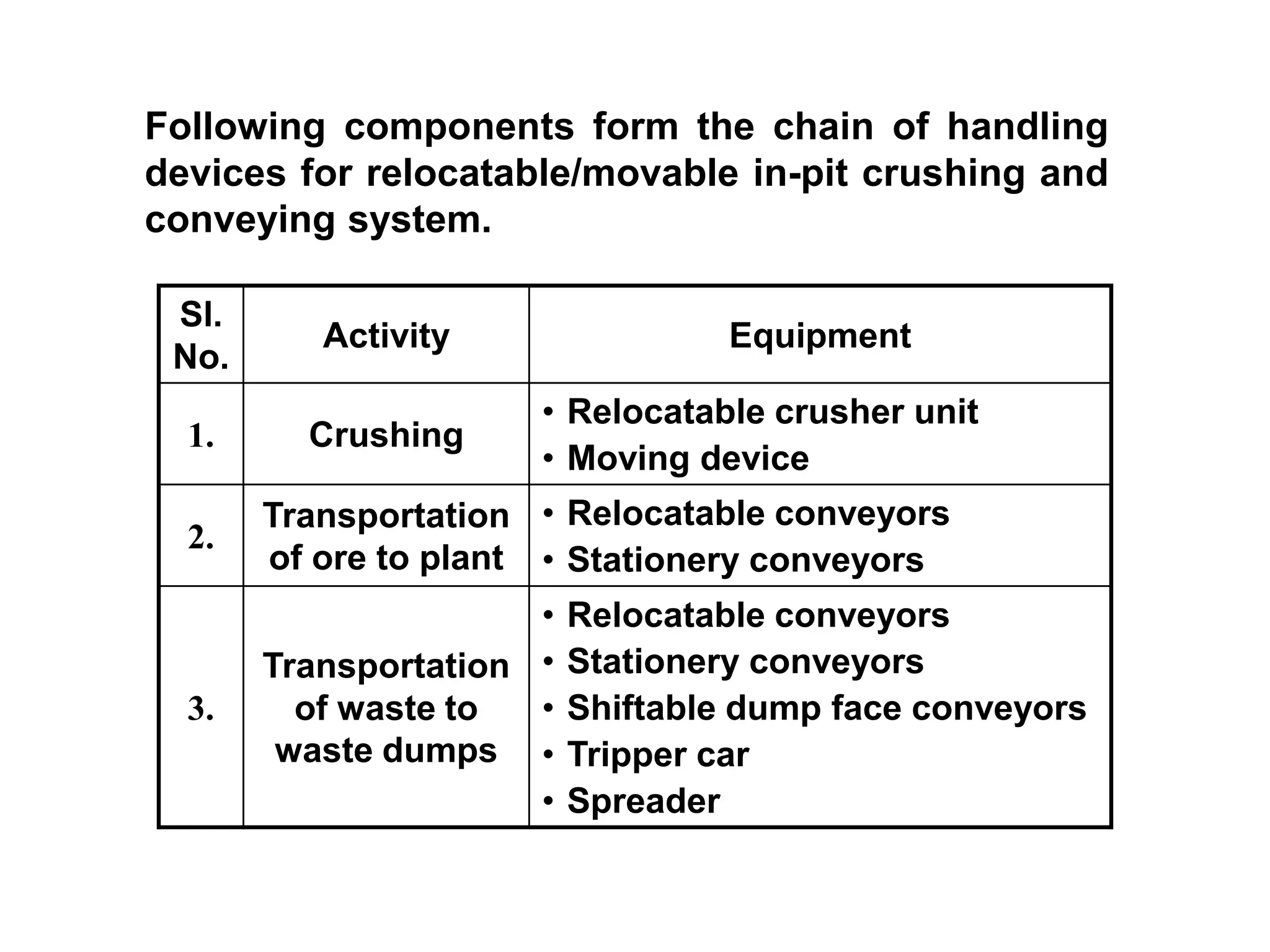

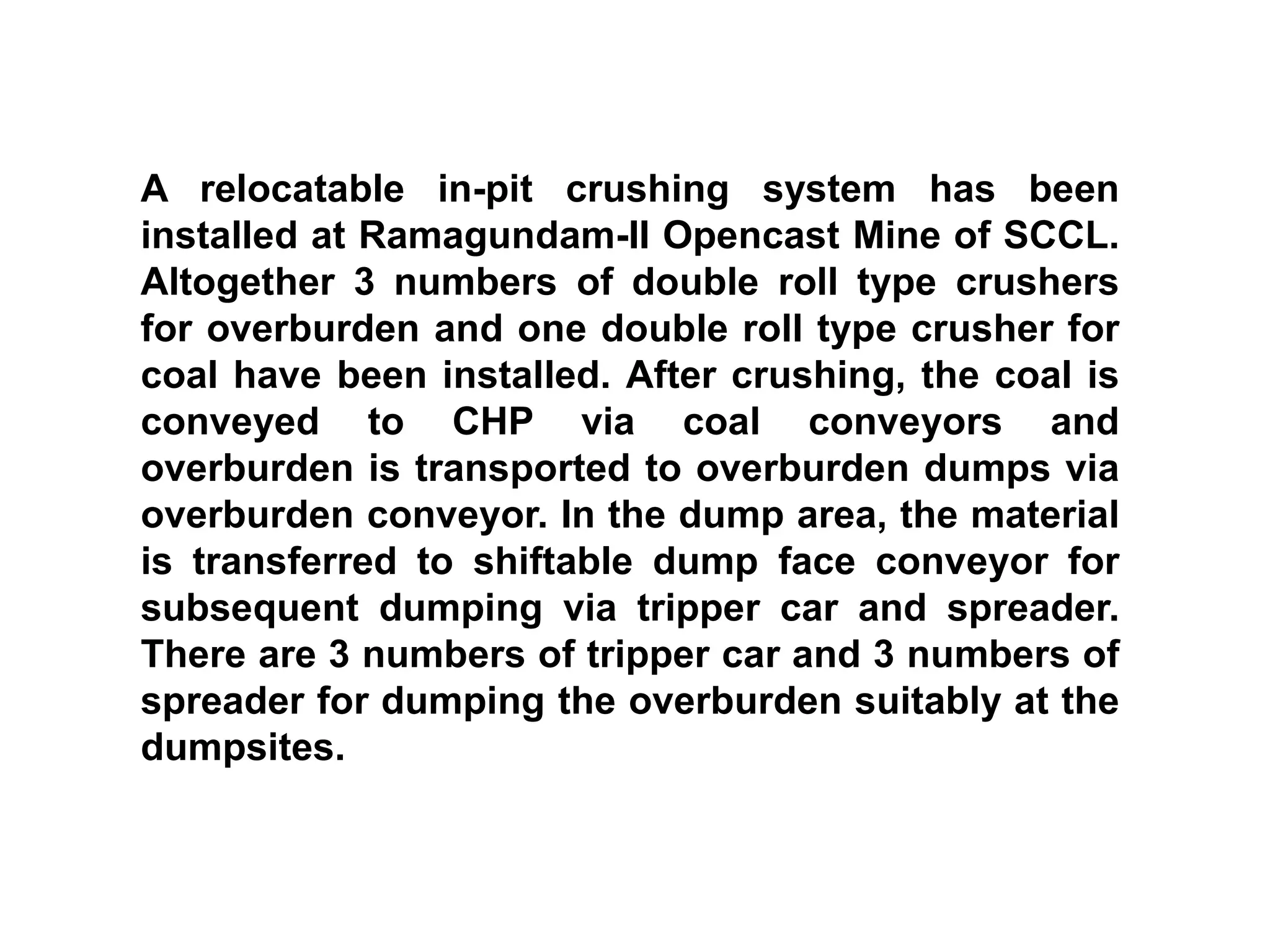

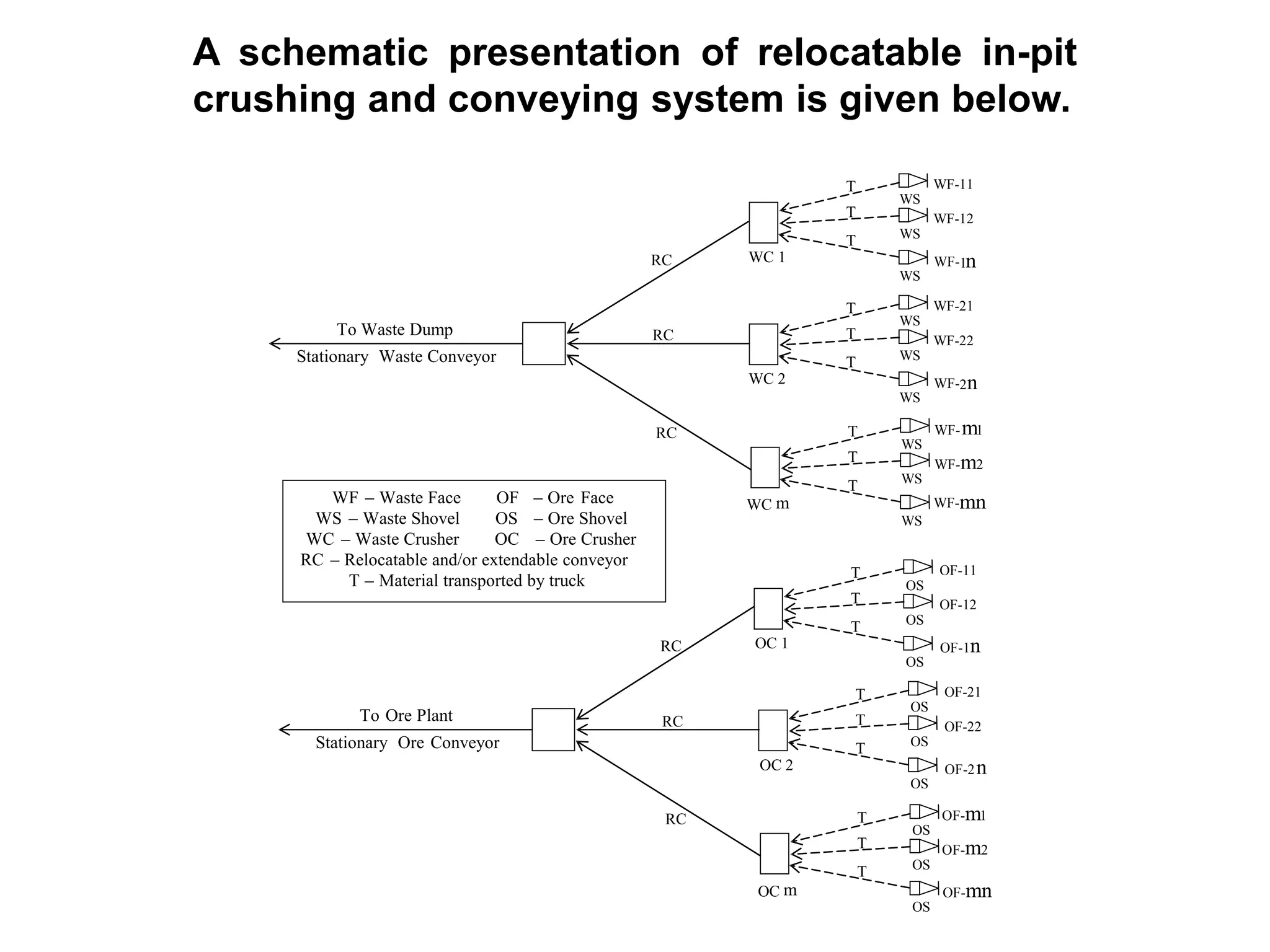

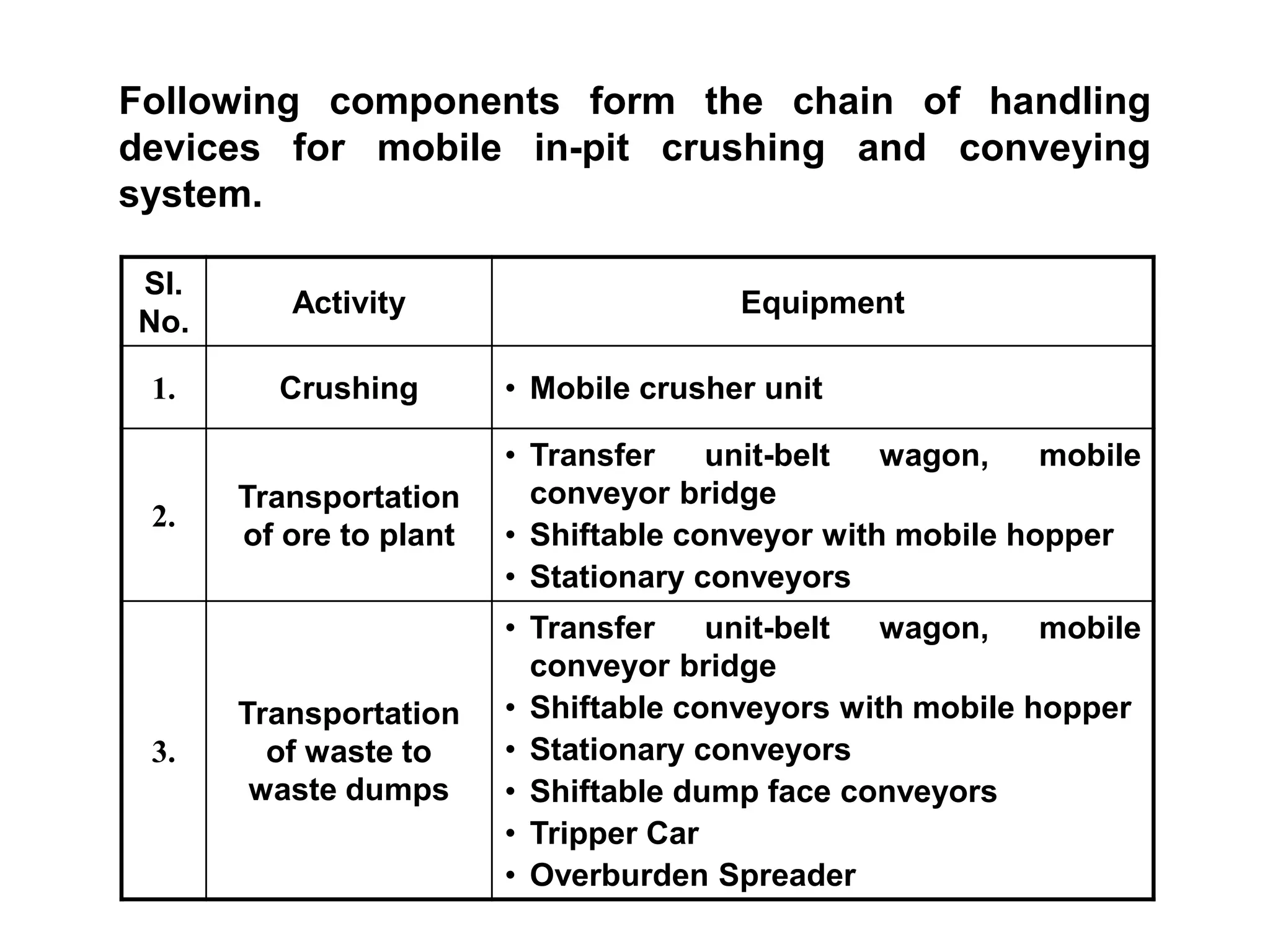

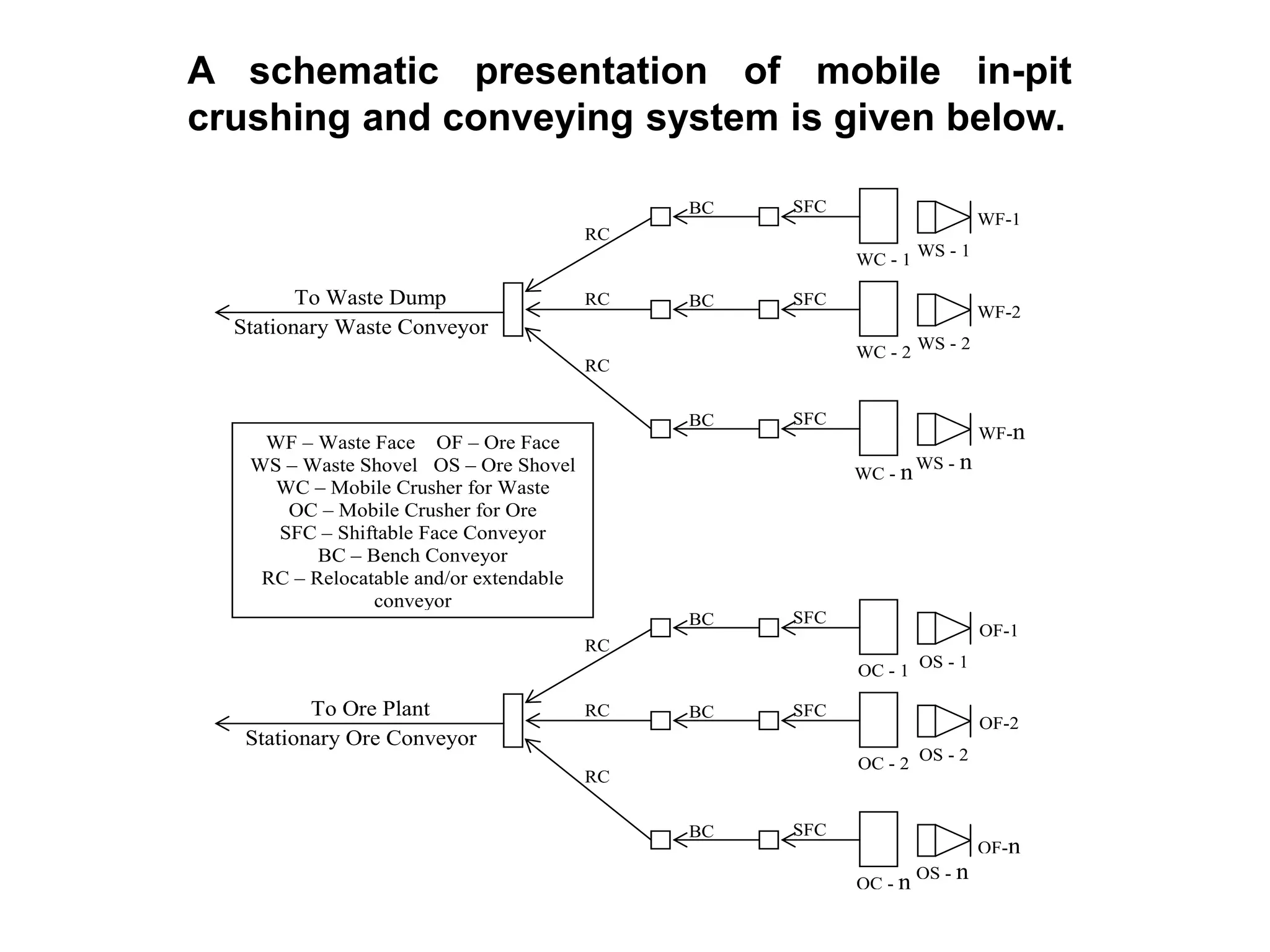

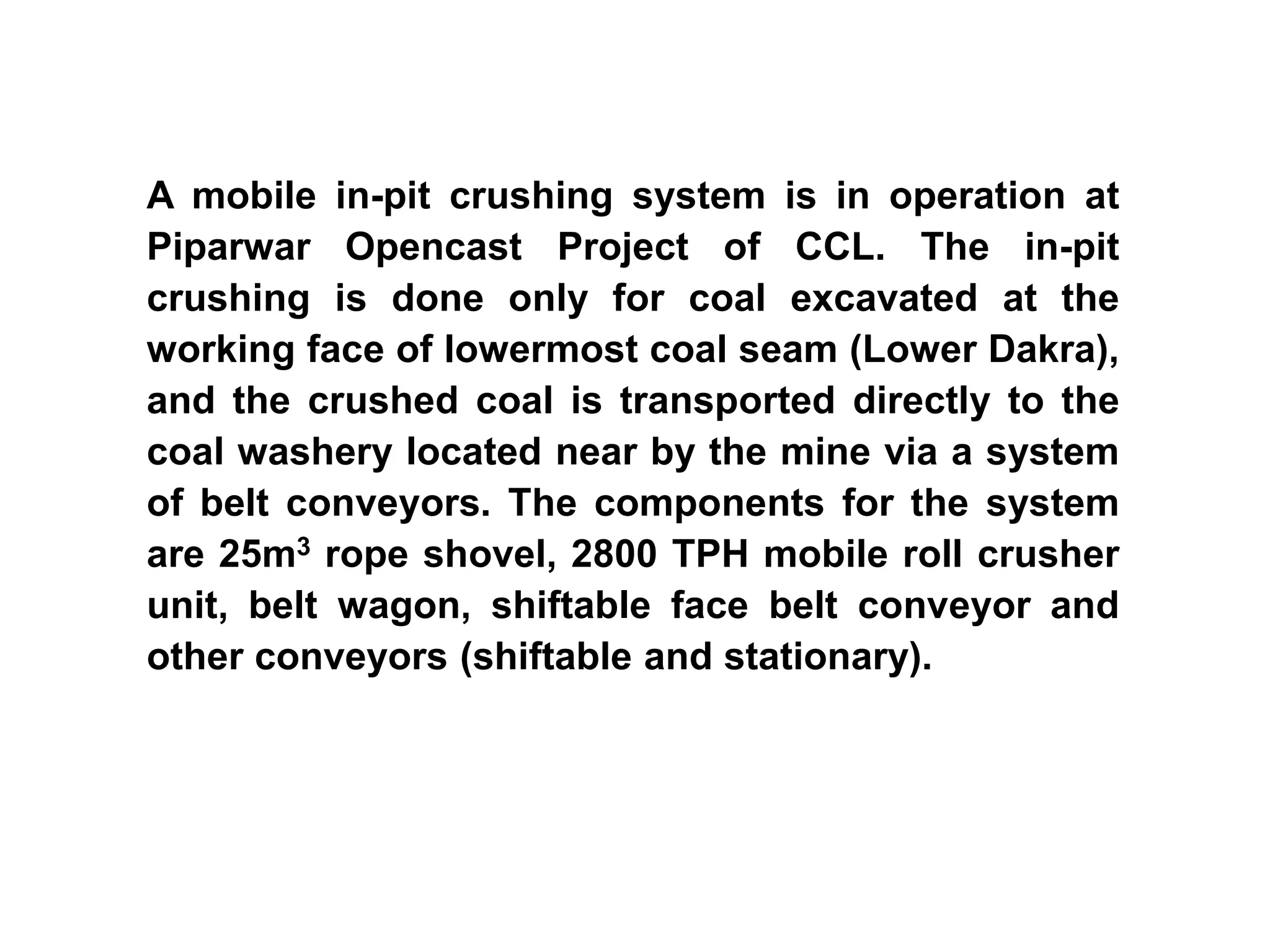

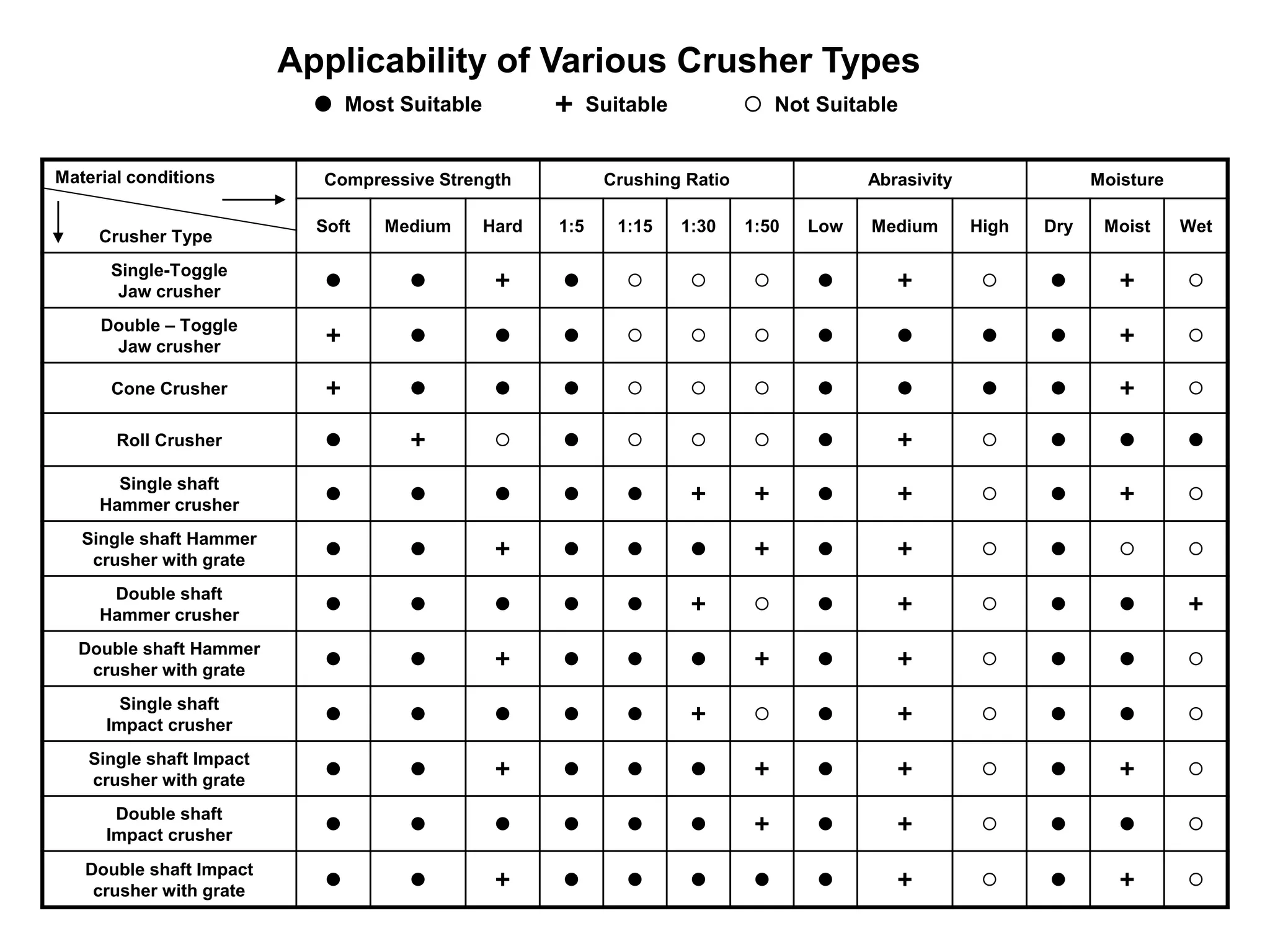

This document discusses in-pit crushing and conveying systems used in surface mines. It describes how stationary, movable, and mobile in-pit crushing systems work, with material excavated from the mine pit brought to large crushers by trucks and then transported via conveyor belts to processing plants or waste dumps. In-pit crushing and conveying systems allow for material transport via more energy efficient conveyor belts instead of diesel trucks, reducing transportation costs, especially for moving large volumes of material over long distances or heights.