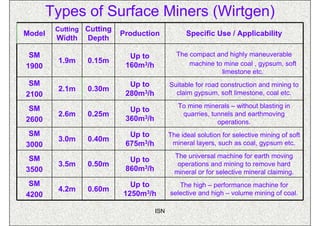

Surface miners are continuously operating mobile machines that cut consolidated soils and semi-solid rocks without drilling or blasting. They have a central cutting drum located between two crawler tracks that can be raised and lowered hydraulically. As the drum cuts the material, it is loaded onto on-board conveyors for transport and loading onto trucks. Surface miners allow for selective mining of coal seams and partings with less dilution and higher quality coal. They are well-suited for mining areas where blasting is prohibited and improve coal recovery.