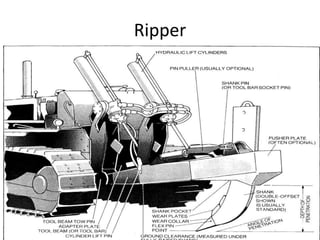

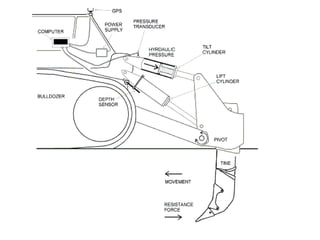

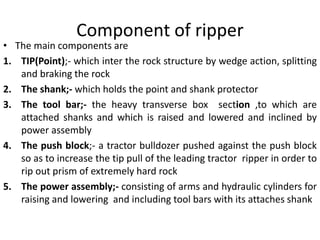

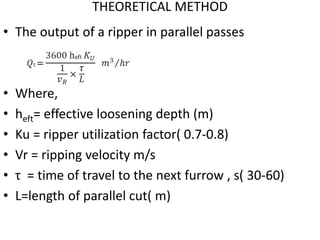

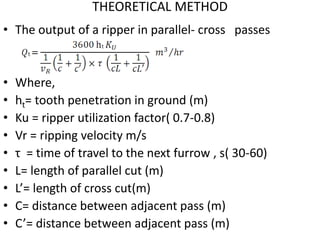

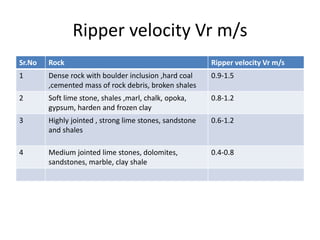

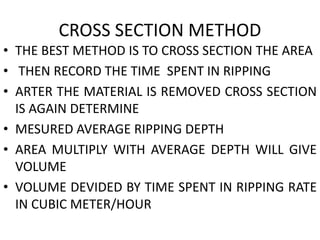

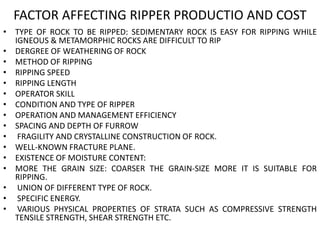

The document discusses ripper production, including the components of a ripper, methods for calculating ripper production rates, factors affecting ripper production, and suggestions for efficient ripping. The main components of a ripper are the tip, shank, tool bar, push block, and power assembly. Methods for calculating ripper production rates include the theoretical method, cross section method, time spent method, and field procedure. Factors like rock type, weathering, ripper type, and operator skill can impact ripper production rates and costs.