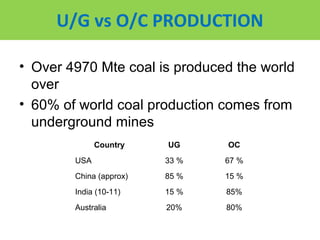

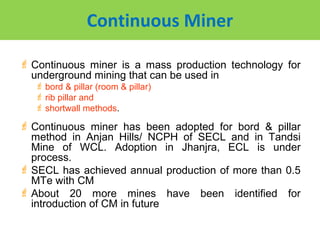

This document discusses continuous miners, an underground coal mining technology. Some key points:

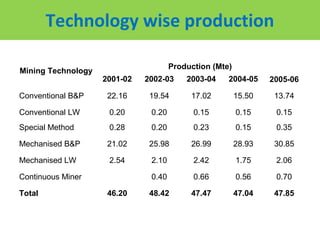

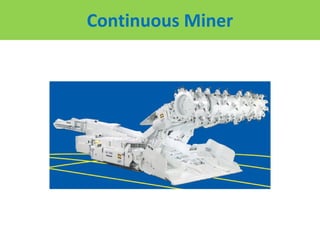

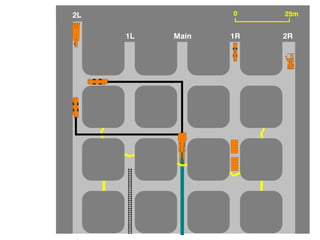

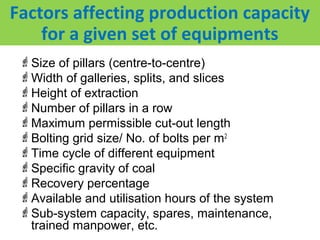

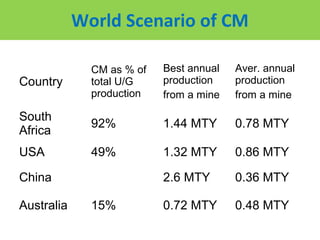

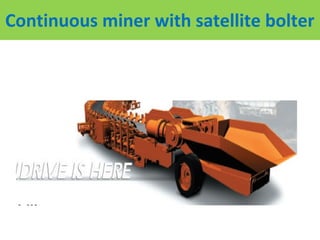

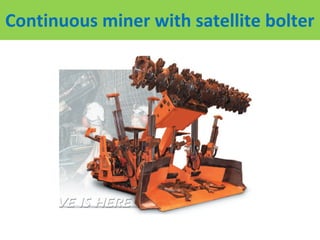

1) Continuous miners use a mass production method and can be used for room and pillar and shortwall mining. Their use has increased production at some CIL mines in India to over 0.5 Mte annually.

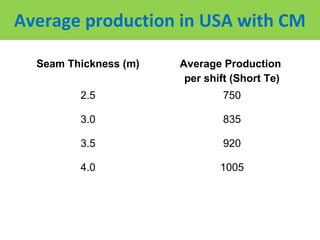

2) Ideal conditions for continuous miners include seam thickness of 1.8-5m, gradients less than 1 in 8, and hard, dry floor conditions. Several CIL mines have been identified to introduce the technology.

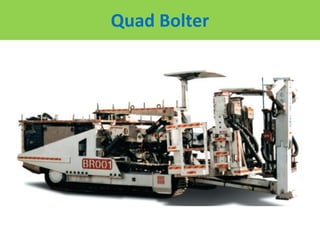

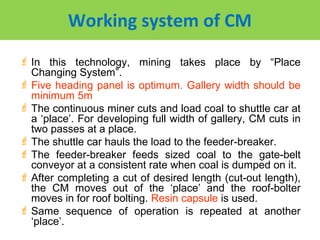

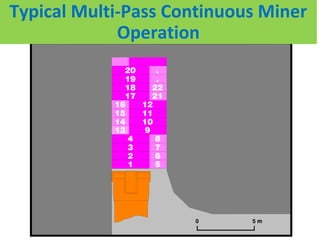

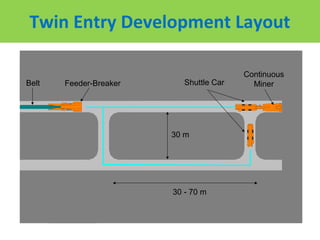

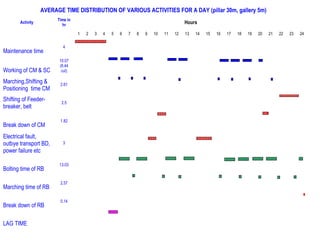

3) The technology involves a continuous miner cutting coal which is loaded onto shuttle cars and transported to a feeder breaker. Roof bolting then occurs before the min