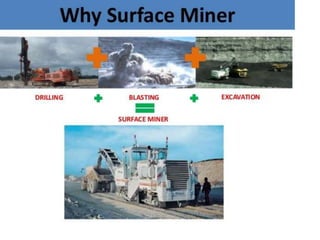

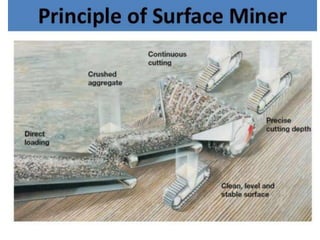

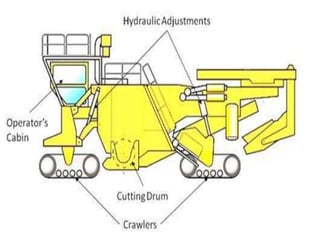

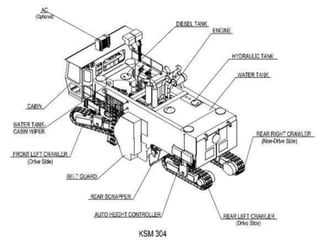

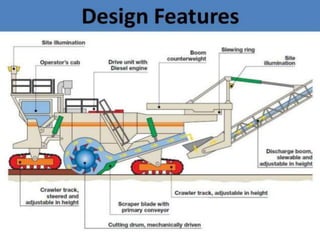

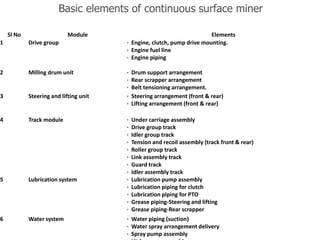

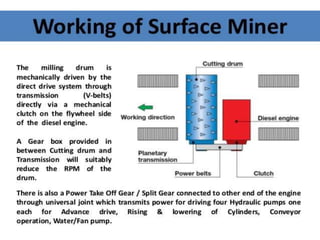

The continuous surface miner is a modular machine that operates by using a rotating cutting drum fitted with cutting tools to cut material from rock formations in layers. As the crawler-mounted machine moves forward, the cutting drum rotates against the direction of travel to cut the material. The cutting tools transport the mined material toward the center of the drum where it can then be loaded onto conveyors. The mined materials can be directly loaded onto trucks, discharged to the side to be mixed, or deposited as a windrow between the miner's crawler tracks.