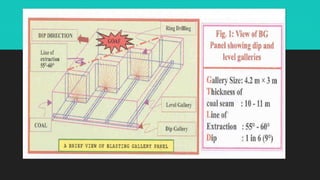

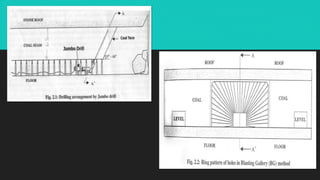

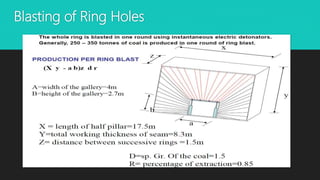

The document discusses the blasting gallery method of underground coal mining, which is effective for extracting thick seams of coal (8-11 meters). It outlines the principle, advantages such as increased extraction rates (75-85%) and safety, as well as limitations including unsuitability for gassy mines. Key operational details include drilling techniques, support systems, ventilation requirements, and methane testing procedures prior to blasting.