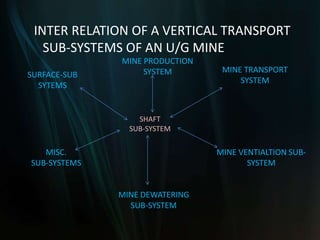

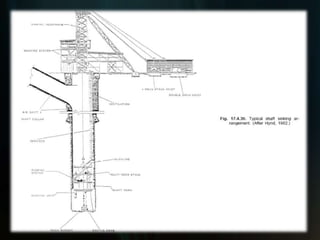

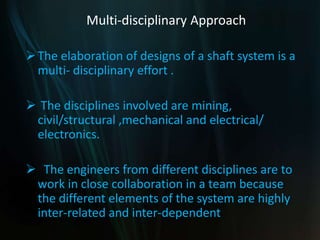

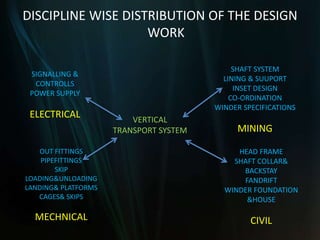

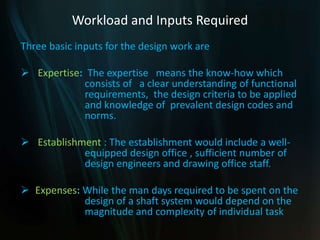

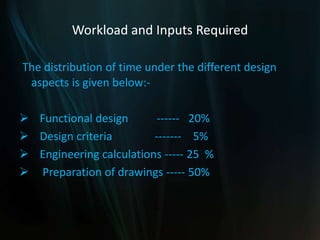

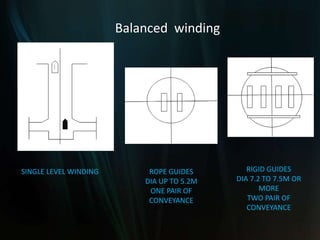

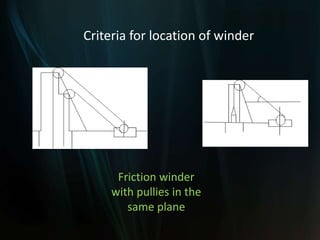

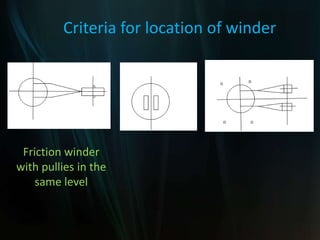

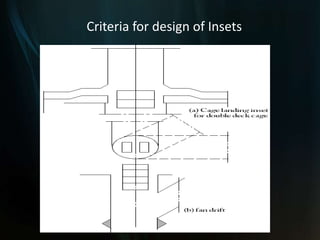

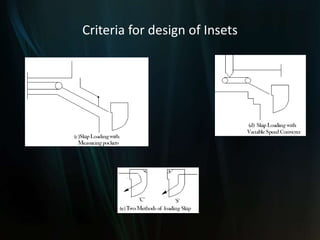

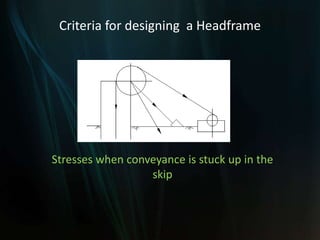

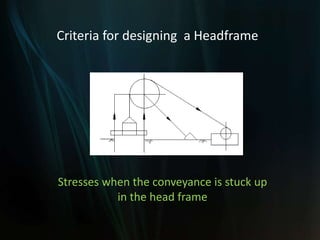

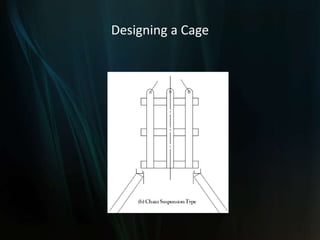

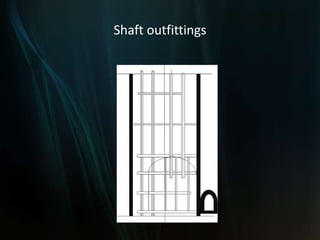

The document discusses key considerations for designing a shaft system for an underground mine. It addresses the interrelation of the shaft subsystem with other mine systems like ventilation, dewatering, and transport. The main elements of a shaft system include the headframe, winder house, shaft collar, fan drift, fittings and conveyances. Designing the shaft requires a multidisciplinary approach and consideration of functional requirements, geological conditions, operational parameters, and statutory regulations. Choice of the winding system, conveyance type, and winder location are important design decisions.