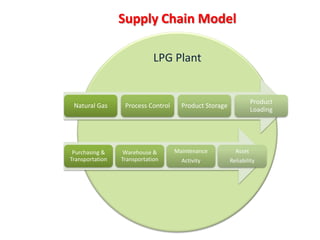

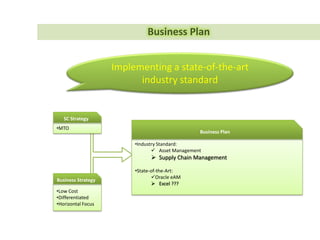

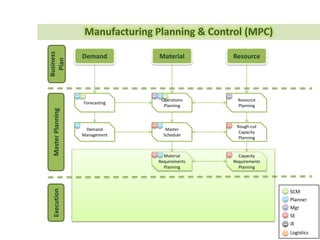

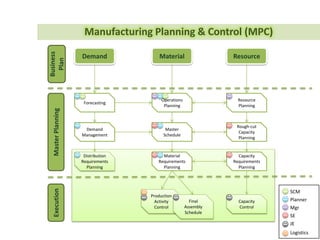

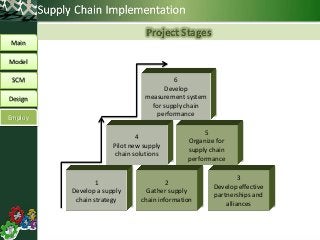

- The document discusses the implementation of an enterprise asset management (EAM) and supply chain management (SCM) system for an LPG plant.

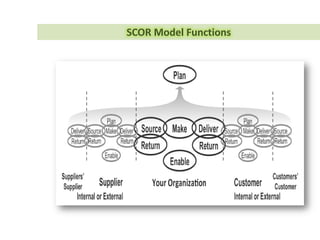

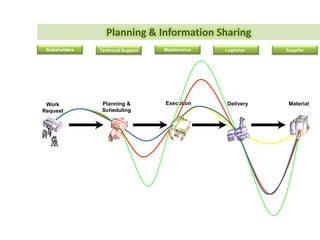

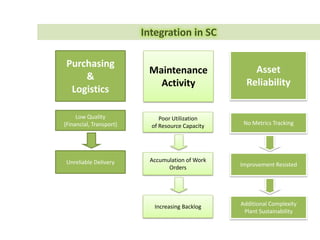

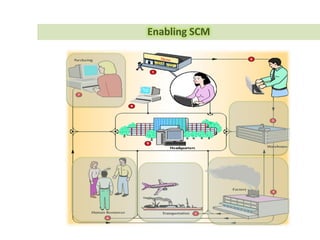

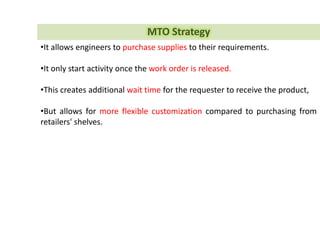

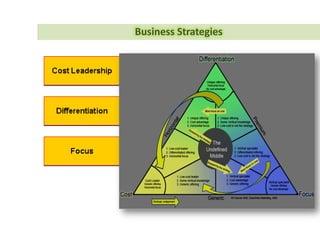

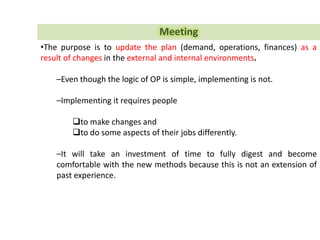

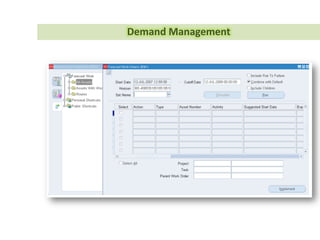

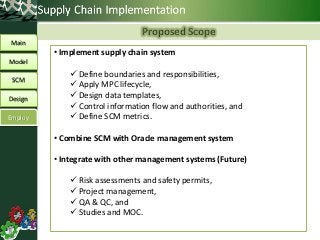

- It proposes implementing a state-of-the-art EAM system like Oracle eAM and integrating it with an industry standard SCM system to improve asset integrity and supply chain functionality.

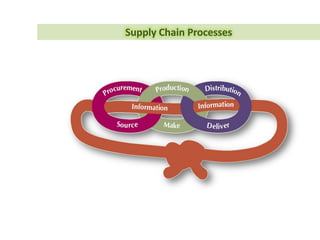

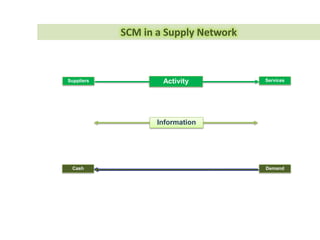

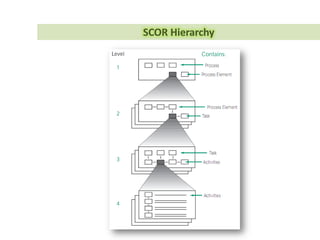

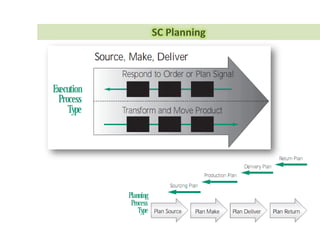

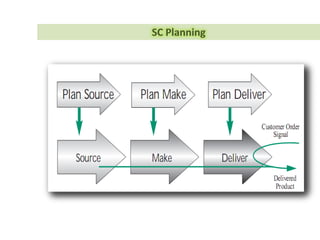

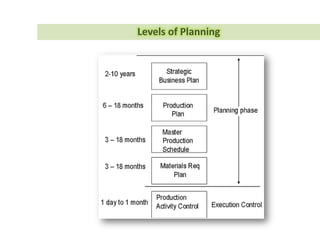

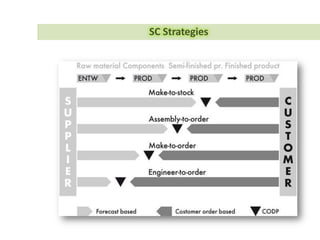

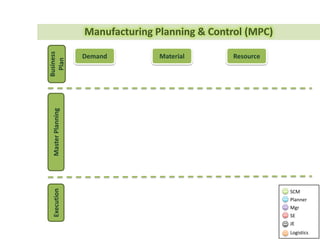

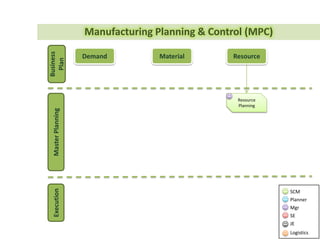

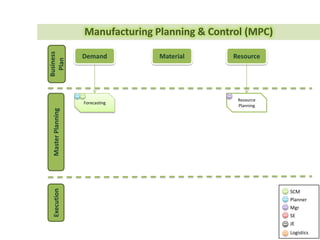

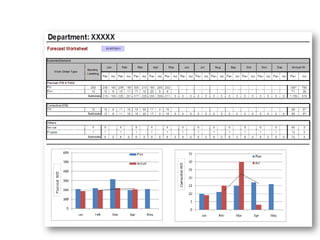

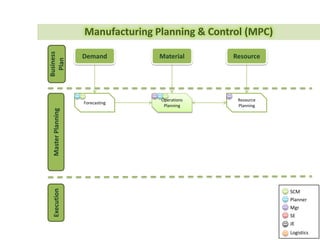

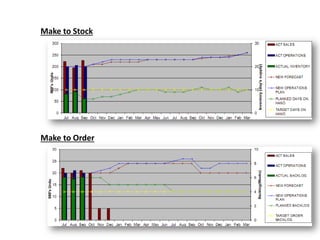

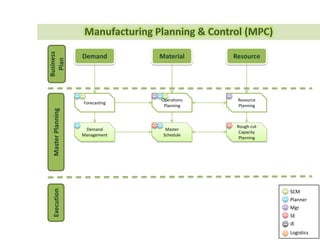

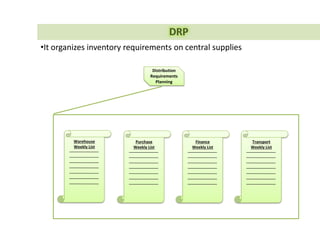

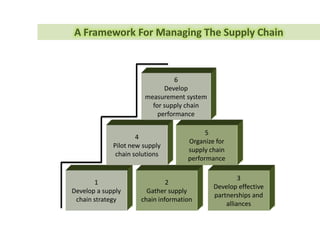

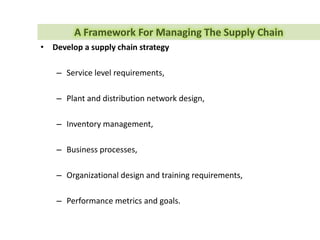

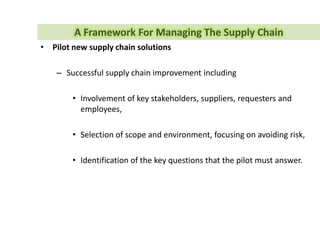

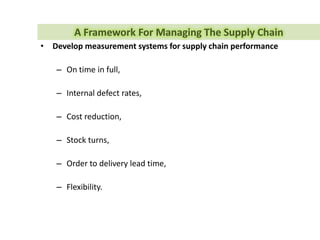

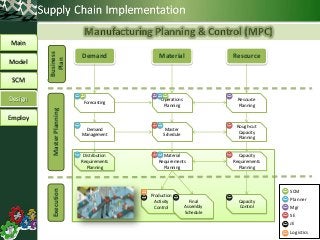

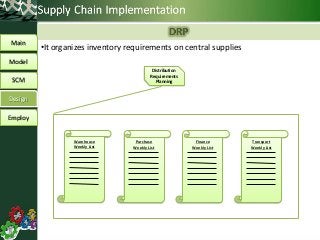

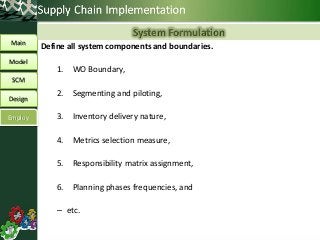

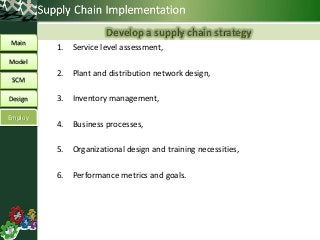

- The scope of work includes defining system boundaries, applying the manufacturing planning and control lifecycle, designing data templates, and establishing metrics to control the information flow and measure SCM performance.