This document summarizes a presentation given by Vincent McGrath on supply chain management. It discusses:

- Exertis Group, which provides distribution and supply chain services, managing over $4 billion annually for more than 10,000 employees globally.

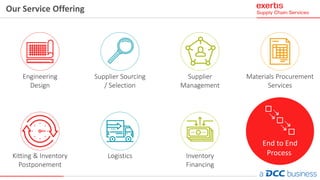

- Exertis Supply Chain Services designs and operates materials supply chains to optimize costs, capital, and complexity for clients.

- Trends impacting supply chain management, like offshoring, globalization, cost management, and the use of technology and data analytics.

- How supply chain management can reduce costs through activities like procurement, inventory management, and vendor consolidation while improving information flow and reducing complexity.