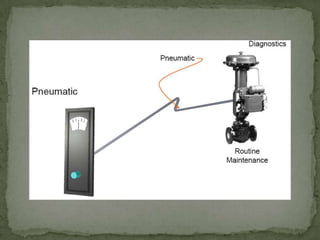

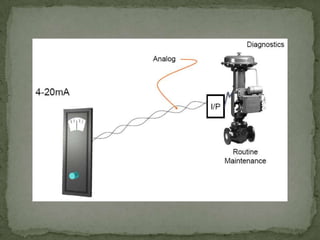

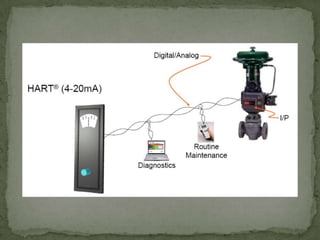

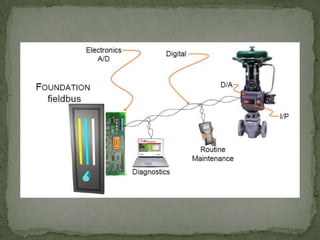

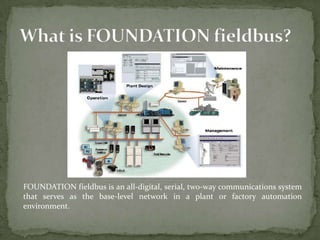

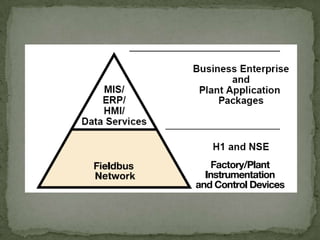

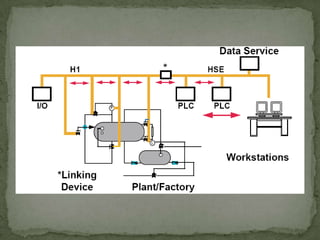

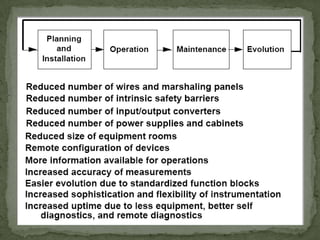

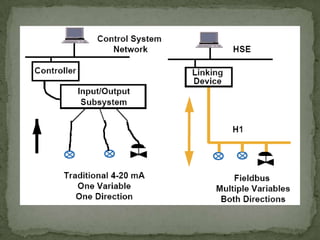

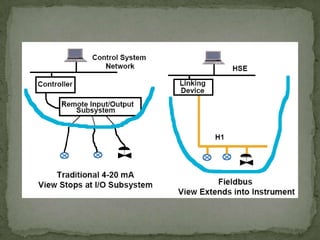

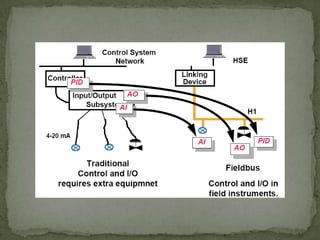

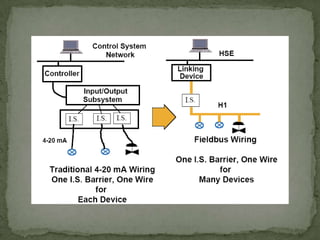

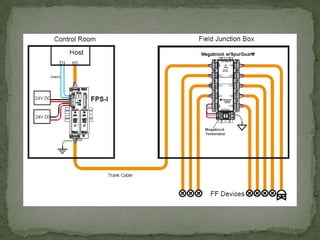

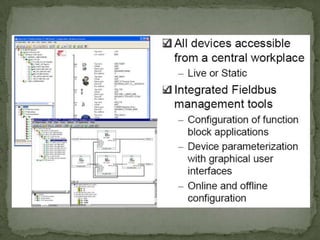

FOUNDATION fieldbus is a digital, two-way communication system used in industrial automation. It has two implementations: H1 operates at 31.25 Kbit/sec over twisted pair wiring to connect to field devices, while HSE operates at 100 Mbit/sec over Ethernet to connect subsystems. FOUNDATION fieldbus offers advantages over traditional analog wiring like supporting multiple devices on one cable pair and transmitting multiple process variables from one instrument. It also enables two-way communication, device diagnostics, and field-level control.