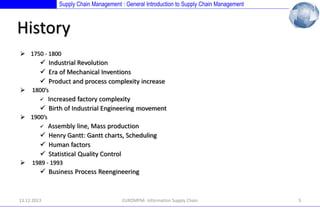

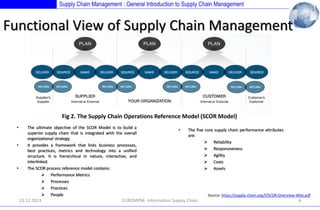

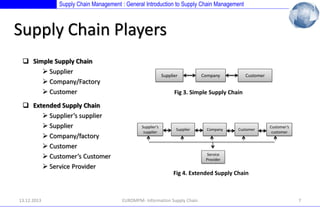

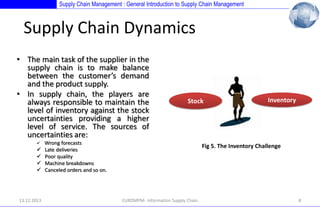

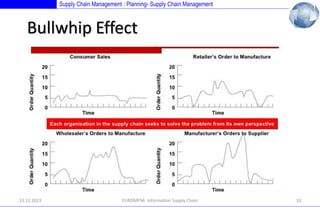

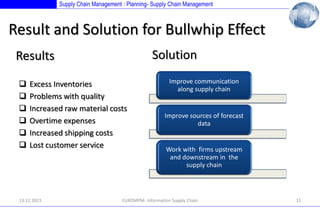

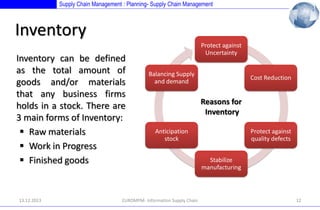

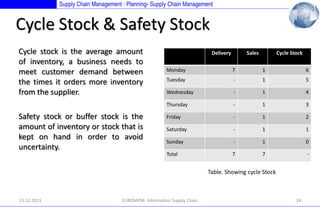

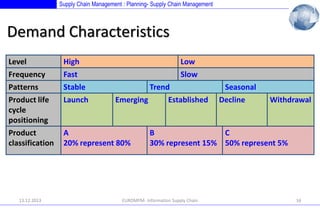

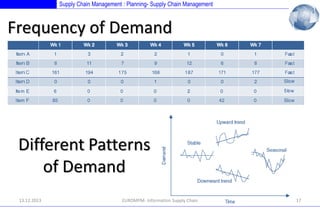

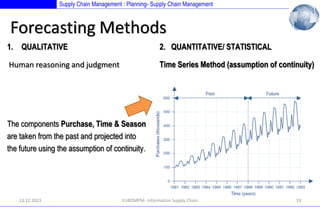

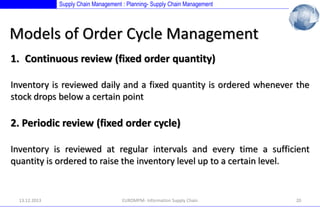

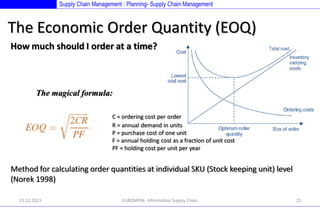

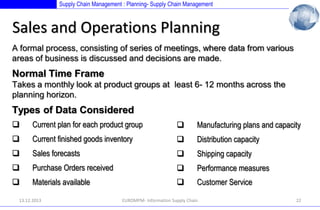

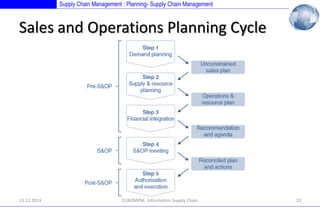

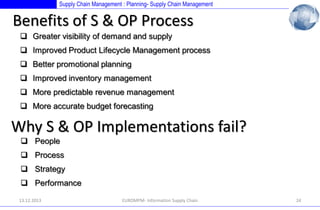

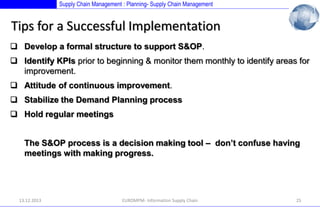

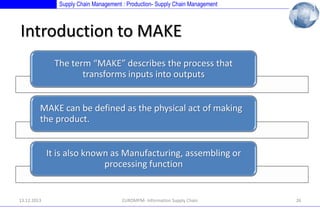

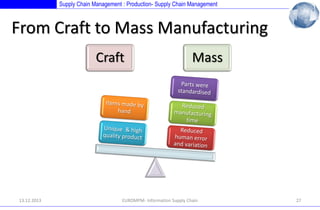

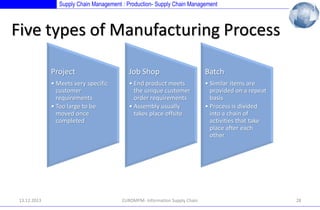

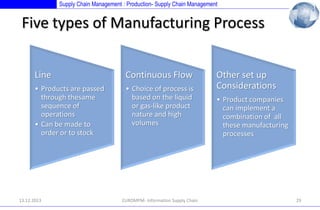

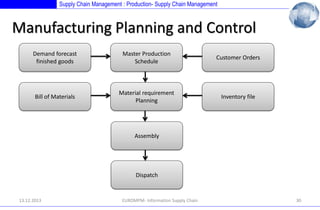

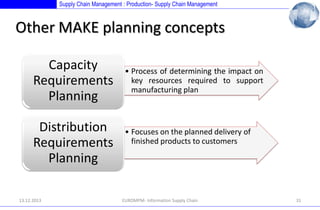

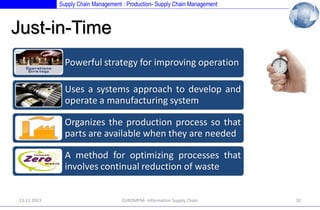

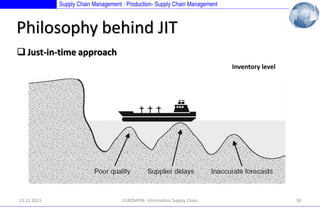

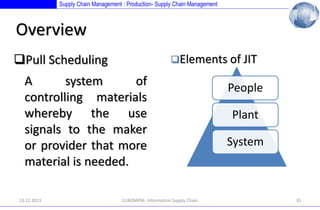

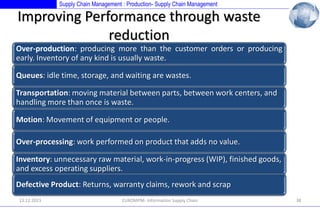

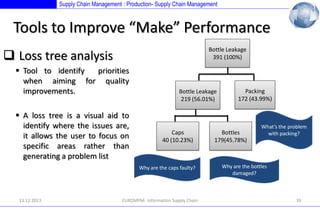

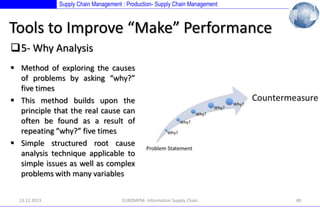

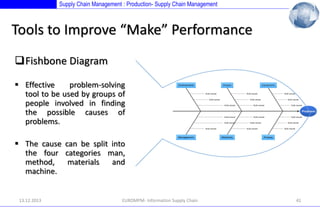

The document provides an overview of supply chain management, detailing its integration of key business processes that deliver products, services, and information to customers and stakeholders. It discusses the historical evolution of supply chain management, key dynamics among supply chain players, inventory management, and planning strategies such as sales and operations planning. Furthermore, it highlights tools for improving production processes, including just-in-time and lean manufacturing strategies, while emphasizing the importance of forecasting, process efficiency, and waste reduction.