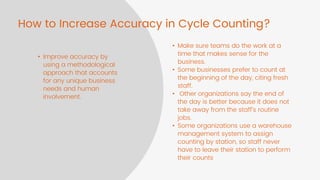

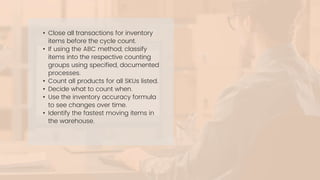

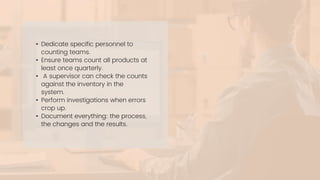

The document provides an overview of inventory cycle counting, detailing best practices, benefits, and methods for effective implementation. It distinguishes between physical inventory and cycle counting, outlines strategies for performing counts, and explains the role of software like NetSuite in enhancing inventory accuracy. Key topics include methods of cycle counting, the importance of inventory accuracy, and recommendations for optimizing the cycle counting process through automation.

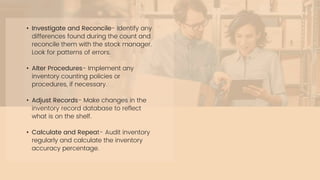

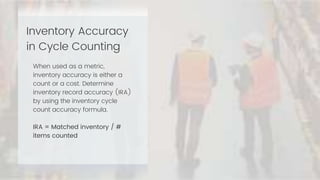

![• The goal of cycle counting is to

identify and rectify any inventory

record discrepancies.

• As with any process, it is helpful to

understand your performance, if it is

improving, and how you perform

compared to industry benchmarks. A

common KPI for this is the IRA

number. You can adapt this formula

for either the number of units or a

dollar total.

• For dollars/units, use the formula:

IRA = [ 1-the sum of the absolute

variance / # the sum of the total

inventory ] x 100](https://image.slidesharecdn.com/inventorycyclecounting101-211215112050/85/Inventory-cycle-counting-101-12-320.jpg)