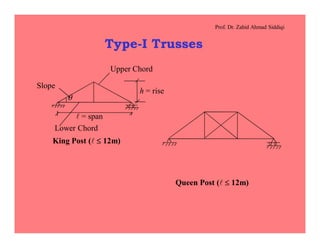

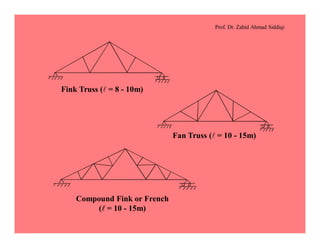

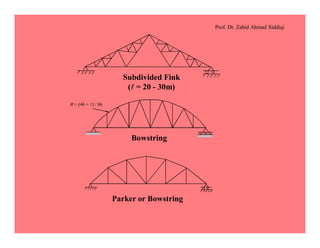

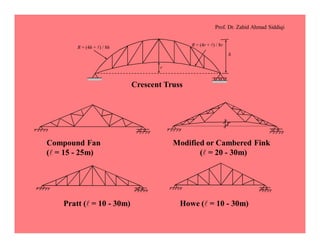

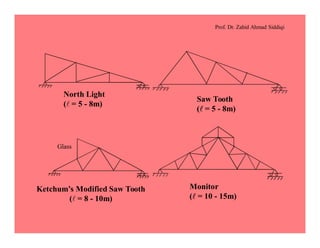

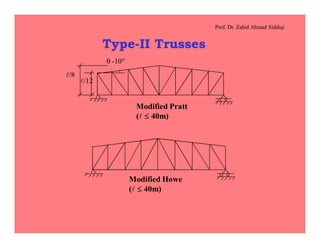

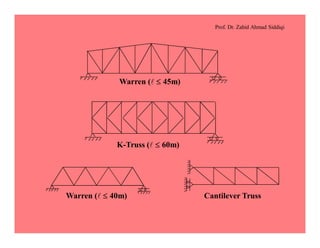

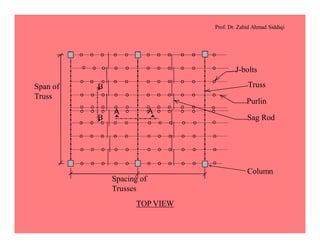

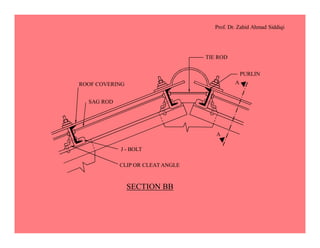

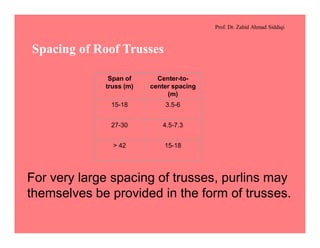

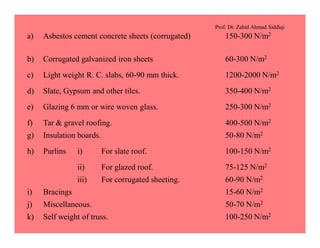

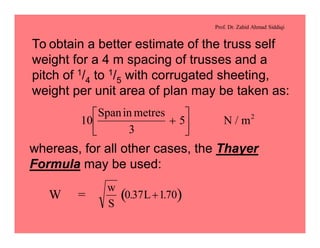

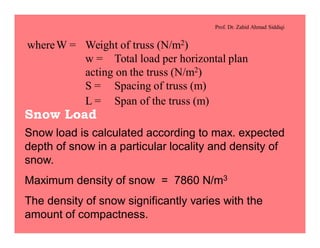

This document discusses the properties and analysis of trusses. It defines a truss as a frame structure where all members experience axial forces. Trusses are analyzed as pin-jointed frames if the joints intersect at a single point and loads are only applied at panel points. The document compares trusses to rigid frames and outlines various truss types including common roof trusses like the Howe, Pratt, Fink and Warren trusses. It also defines related terms like pitch, rise, purlins and loads on truss roofs.