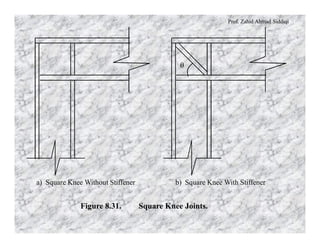

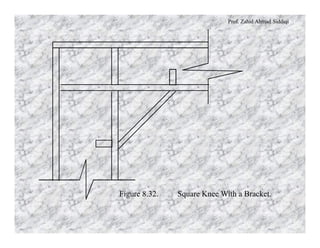

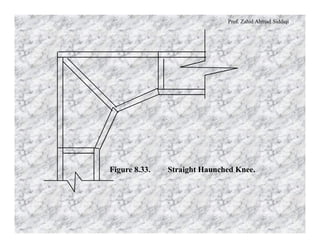

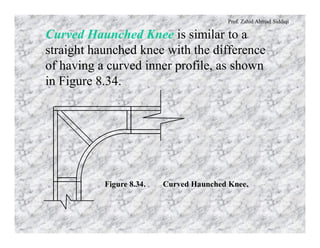

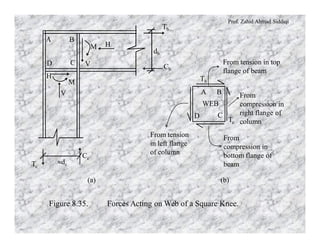

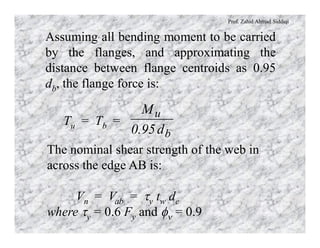

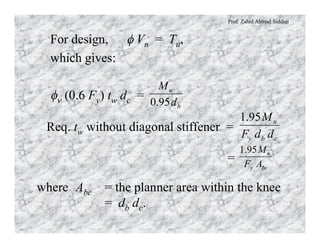

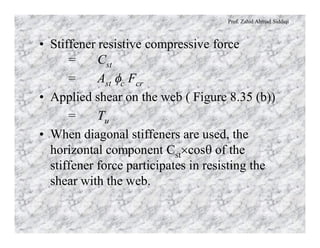

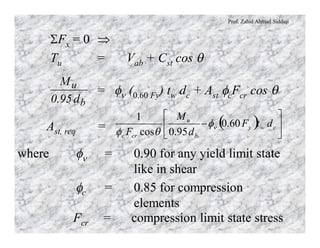

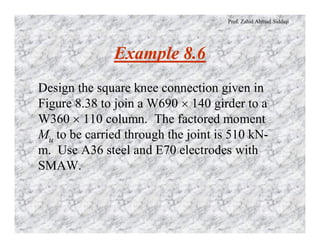

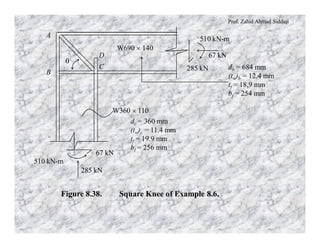

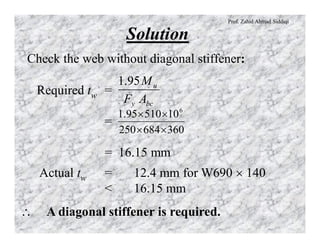

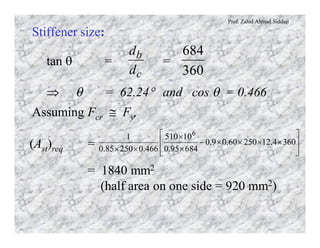

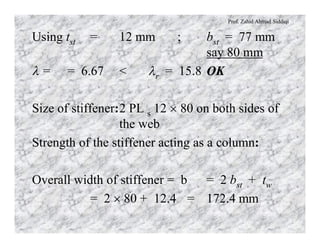

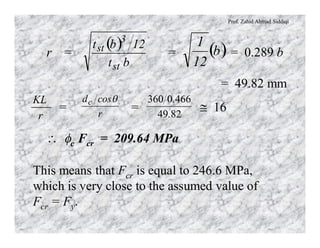

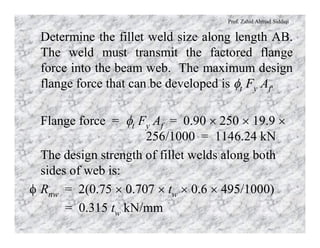

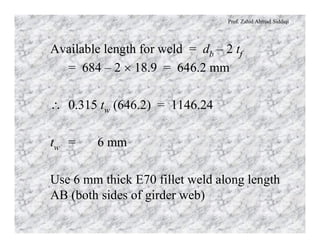

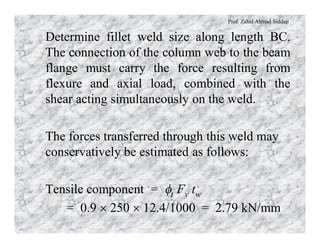

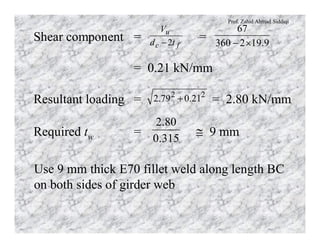

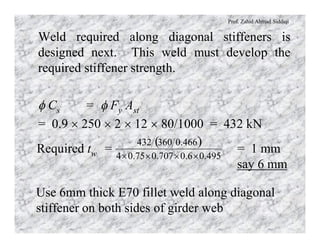

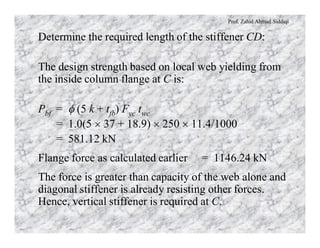

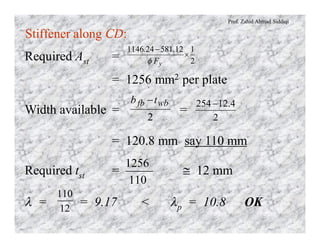

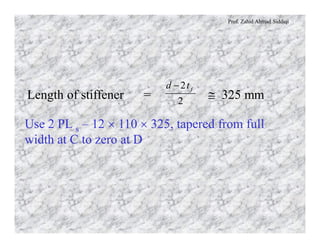

This document discusses different types of rigid frame knee connections used to join beams and columns. Square knee joints are described, with and without diagonal stiffeners. Other knee types include square knees with brackets, straight haunched knees, and curved haunched knees. Straight haunched knees provide reasonable stiffness and rotation capacity at a lower cost than other options. The document provides design procedures and an example problem for sizing the components of a square knee connection between a W690×140 beam and W360×110 column.