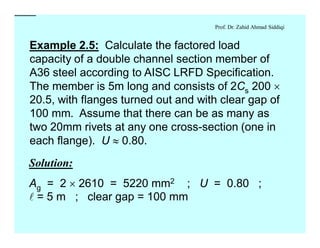

The document discusses the design procedure for selecting structural steel members according to the Load and Resistance Factor Design (LRFD) method. It provides examples of calculating the load capacity of angle sections, double channel sections, and W-sections. General considerations for selecting sections are also outlined, such as compatibility with connections, minimizing weight, and checking slenderness ratios. Members that experience stress reversal are discussed, outlining three cases to determine whether to consider tensile or compressive forces in design.

![Prof. Dr. Zahid Ahmad Siddiqi

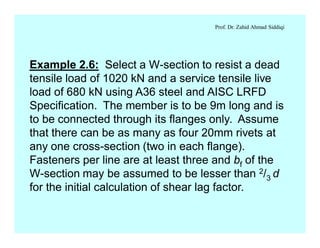

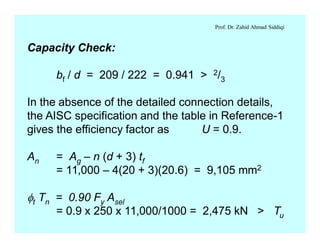

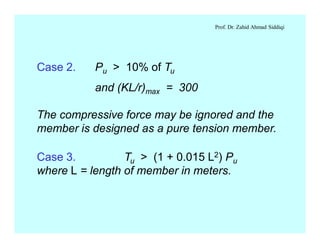

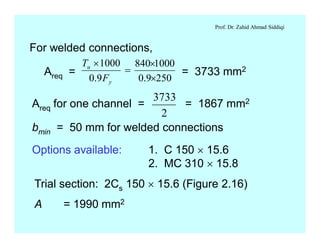

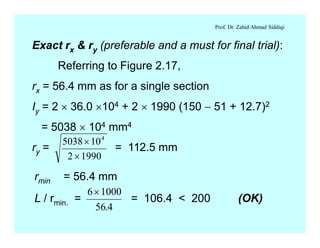

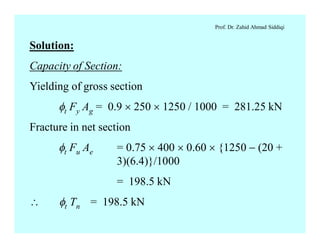

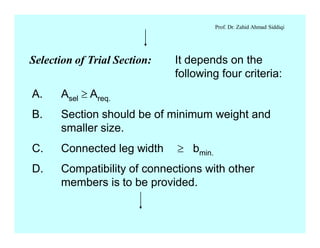

Block Shear Failure Along Path a-b-c:

Agv = (76 + 76 + 38)(6.4) = 1216 mm2

Anv = 1216 – (2.5)(20 + 3)(6.4) = 848 mm2

Ant = 243.2 – (0.5)(20 + 3)(6.4) = 169.6 mm2

Ubs = 1.0

f Rn = lesser of

1. 0.6 Fu Anv + Ubs Fu Ant

= 0.75/1000 [0.6 ´ 400 ´ 848 + 1.0 ´ 400 ´ 169.6]

= 203.52 kN](https://image.slidesharecdn.com/steelstrucurelec5-200810021432/85/Steel-strucure-lec-5-3-320.jpg)

![Prof. Dr. Zahid Ahmad Siddiqi

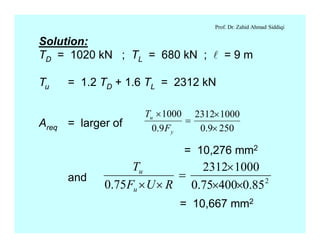

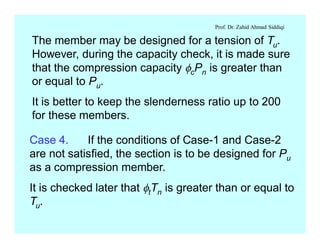

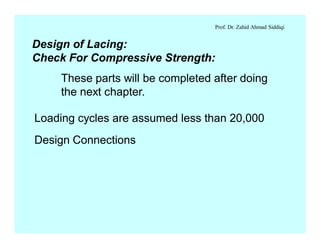

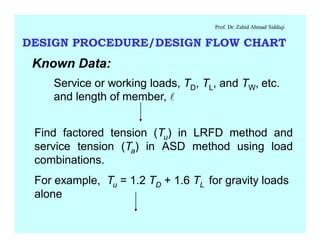

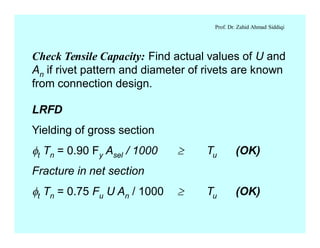

2. 0.6 Fy Agv + Ubs Fu Ant

= 0.75/1000 [0.6 ´ 250 ´ 1216 + 1.0 ´ 400

´ 169.6]

= 187.68 kN

f Rn = 187.68 kN

Hence, block shear failure is the governing limit state

and factored capacity of the member is reduced from

198.5 kN to 187.68 kN due to it.](https://image.slidesharecdn.com/steelstrucurelec5-200810021432/85/Steel-strucure-lec-5-4-320.jpg)

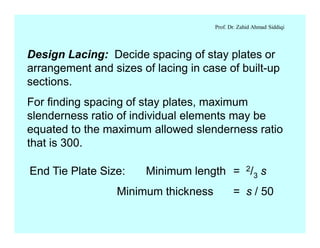

![Prof. Dr. Zahid Ahmad Siddiqi

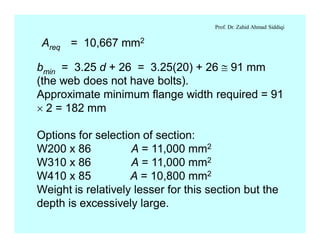

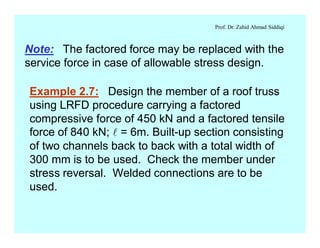

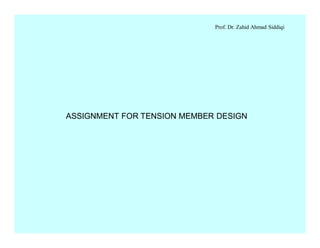

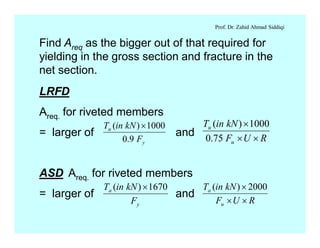

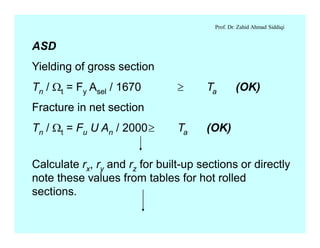

An = Ag - n(d + 3)tf

= 2 ´ [2610 - 2 (20 + 3) ´ 9.9]

= 4309.2 mm2

ftTn = lesser of

1. ft Fy Ag / 1000

= 0.90´250´2´2610 / 1000 = 1174.5 kN

2. ft Fu U An / 1000

= 0.75´400´0.80´4309.2/1000 = 1034.2 kN

= 1034.2 kN](https://image.slidesharecdn.com/steelstrucurelec5-200810021432/85/Steel-strucure-lec-5-15-320.jpg)

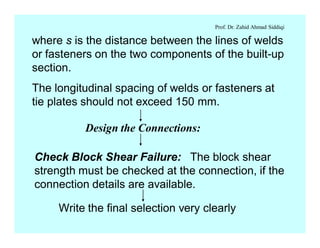

![Prof. Dr. Zahid Ahmad Siddiqi

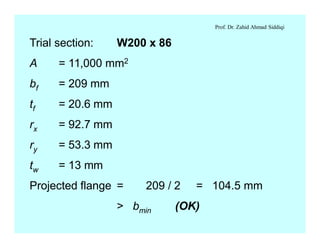

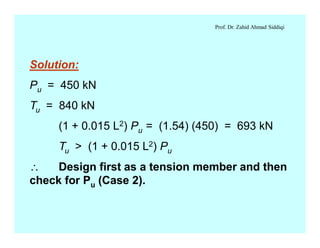

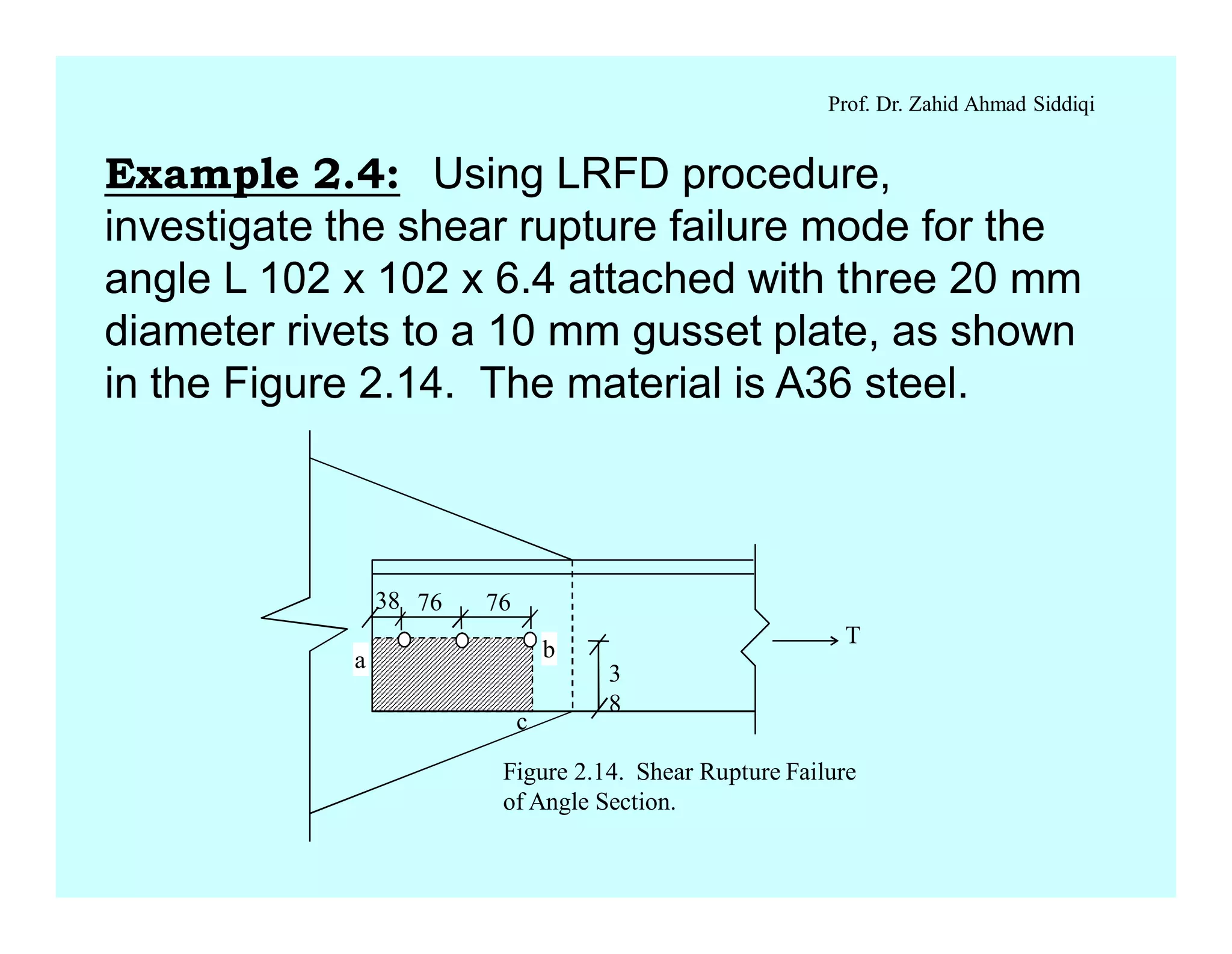

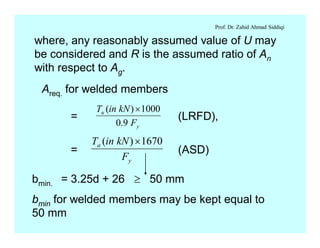

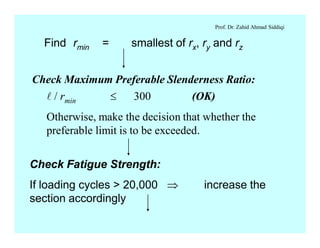

Iy about individual centroid = 63.7 ´ 104 mm4,

x = 14 mm

Iy (built-up) = [63.7 ´ 104 + 2610 (50 + 14)2] ´ 2

= 2265.5 ´ 104 mm4

rmin = ry = 65.88 mm

L / r = 5000 / 65.88 = 75.9 < 300 (OK)

Loading cycles are assumed to be less than

20,000 and hence no reduction in strength due to

fatigue is considered.

The factored tensile capacity is 1034.2 kN

ry =

26102

105.2265 4

´

´

= 65.8 mm](https://image.slidesharecdn.com/steelstrucurelec5-200810021432/85/Steel-strucure-lec-5-16-320.jpg)