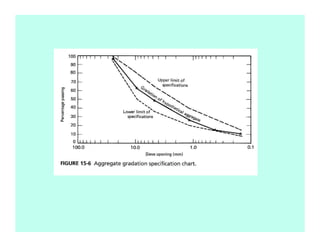

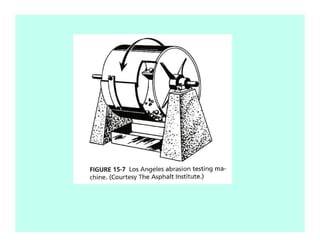

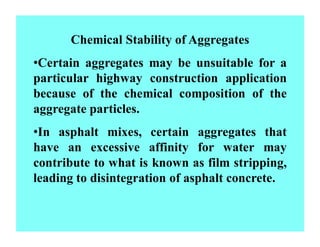

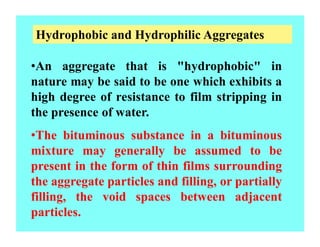

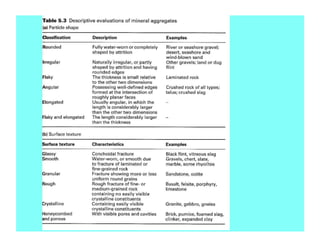

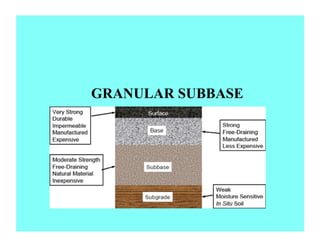

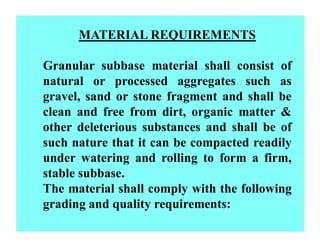

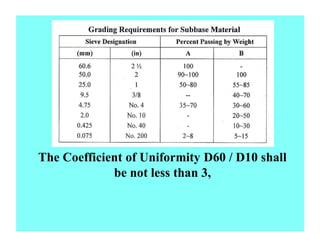

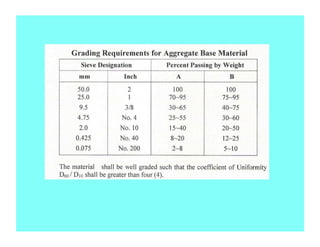

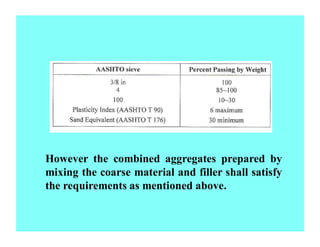

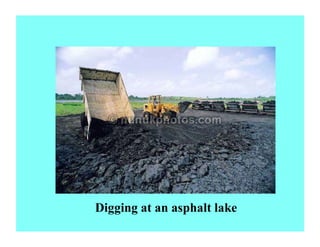

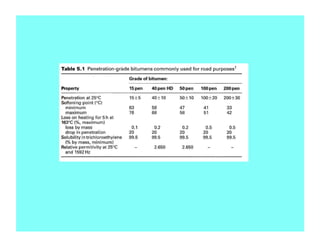

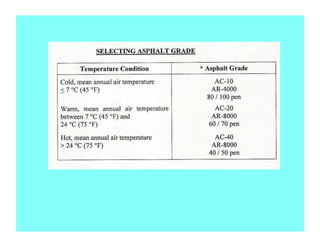

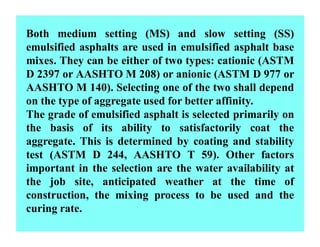

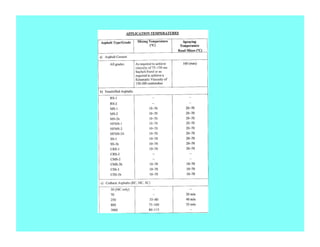

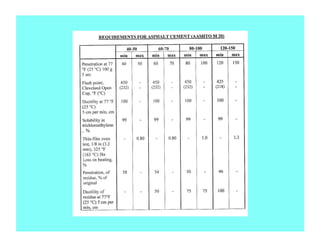

This document discusses various materials used in highway construction. It describes aggregates, which are granular materials used in bases, subbases and backfill. Important properties of aggregates include particle size and hardness. Particle size distribution is determined through grain-size analysis and sieving. Hardness is measured using tests such as the Los Angeles abrasion test. Bituminous materials, commonly known as asphalt, are also discussed. Types of asphalt include asphalt cement and cutback asphalt. Specifications and tests for aggregates and asphalt are provided according to standards like AASHTO and ASTM.