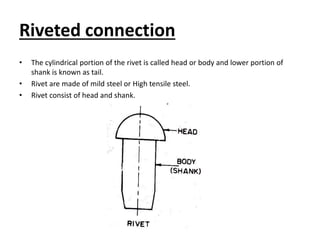

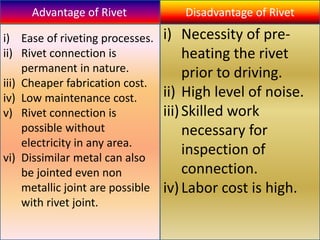

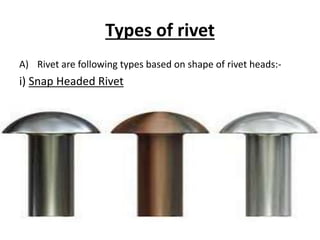

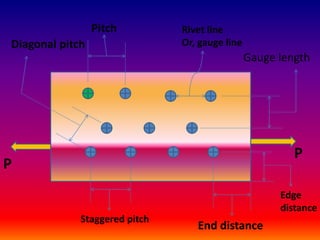

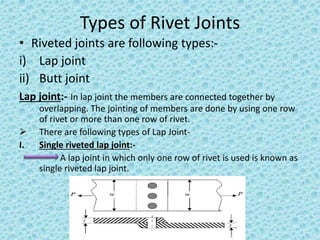

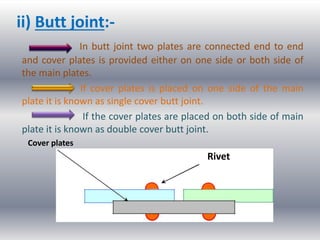

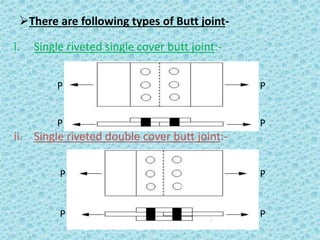

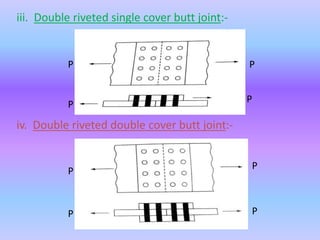

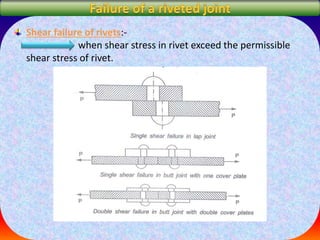

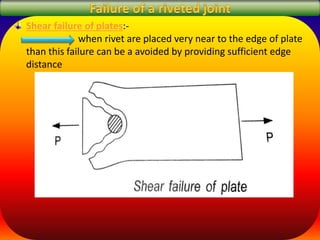

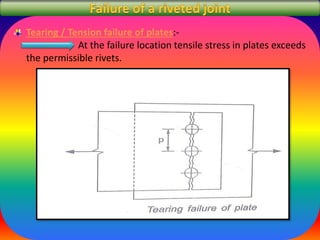

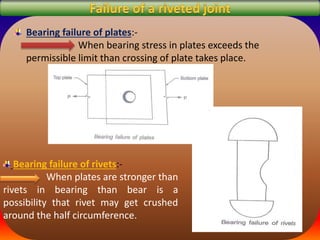

This document discusses riveted connections in steel structures. It describes the different types of rivets, including their shape and method of installation. Some key types are snap headed rivets, pan headed rivets, and flat counter sunk rivets. It also outlines the advantages and disadvantages of riveted connections. Advantages include ease of installation without electricity, while disadvantages include noise and required skilled labor. The document further explains different riveted joint configurations, including lap joints and butt joints, providing examples of single and double riveted versions of each. Finally, it briefly outlines potential failure modes of riveted connections, such as shear failure of rivets or plates, and bearing failure of plates or