This document discusses lap joints, bolted connections, and riveted connections. It provides details on:

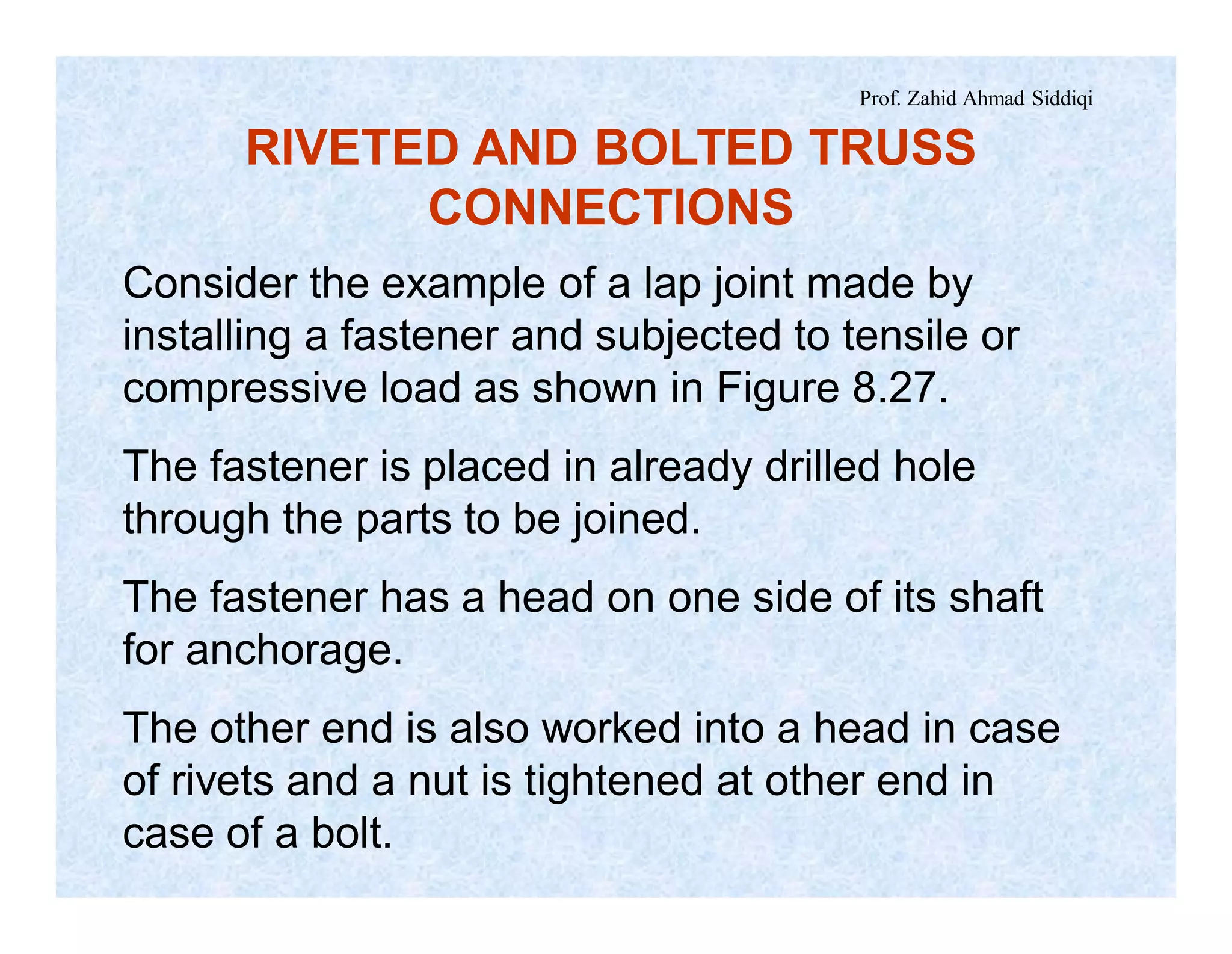

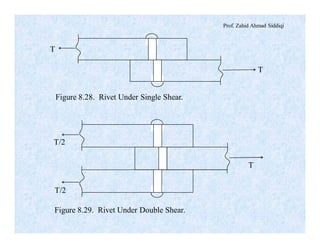

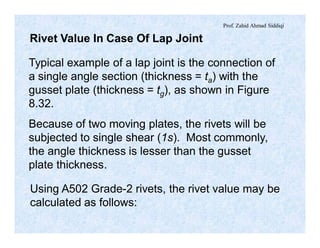

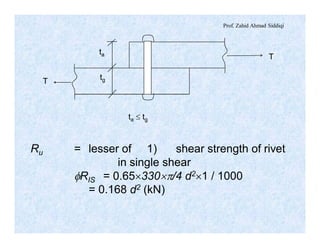

- The components and stresses involved in a basic lap joint using a single fastener under tension or compression.

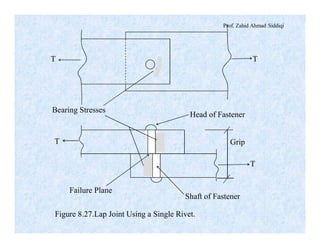

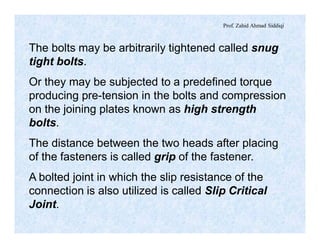

- Requirements for bolted connections including minimum pretension values for high-strength bolts and methods for measuring pretension.

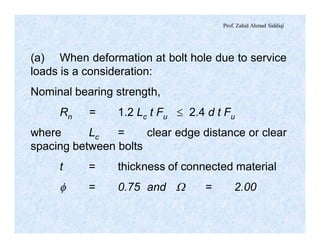

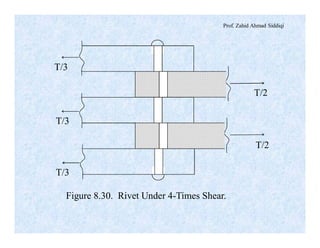

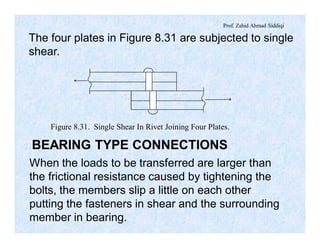

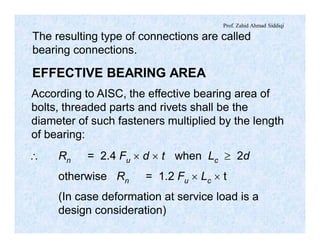

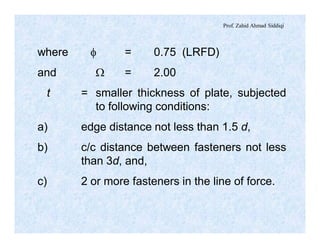

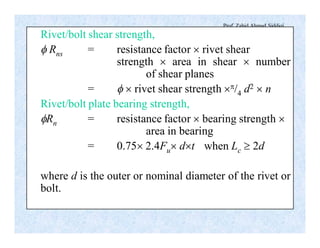

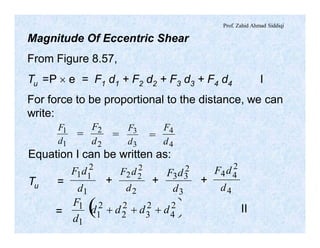

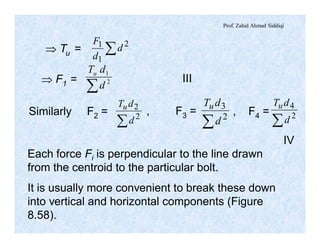

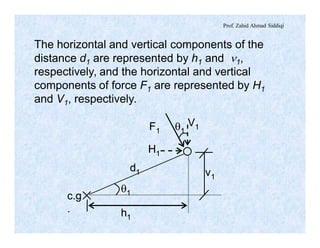

- Types of stresses fasteners experience including shear stresses at the interface of joined parts and bearing stresses transmitted into the surrounding plates.

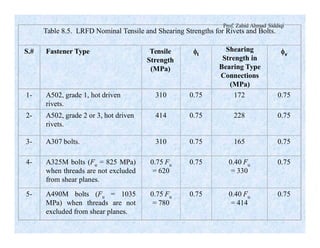

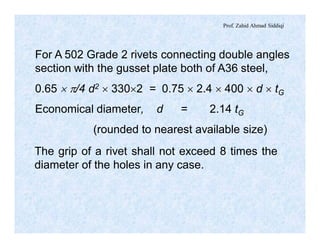

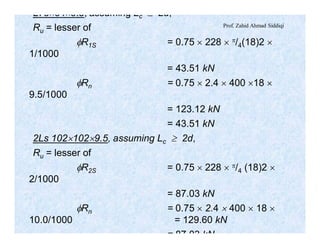

- Properties and grades of rivets commonly used in structural connections as well as their tensile and shear strengths.

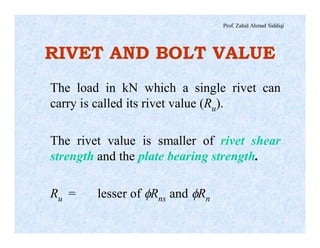

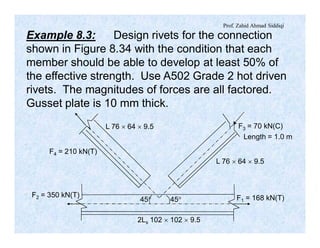

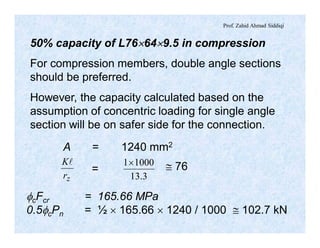

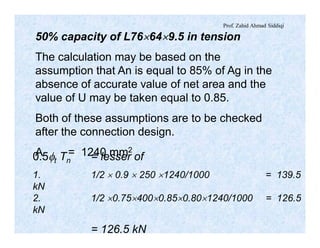

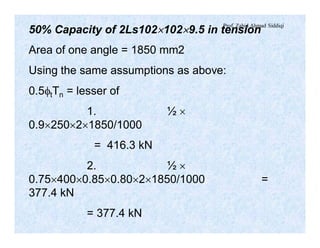

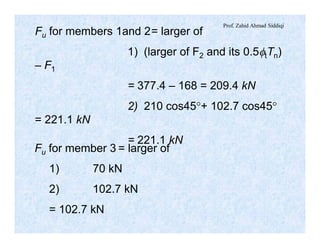

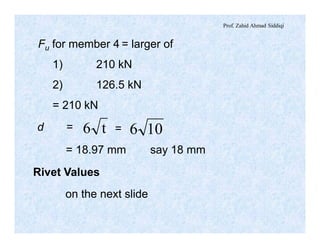

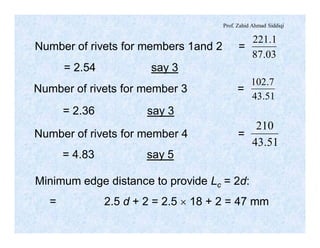

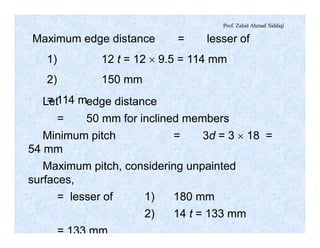

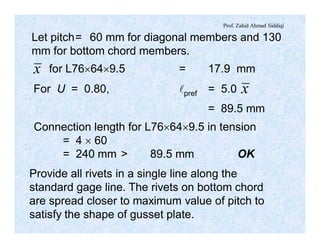

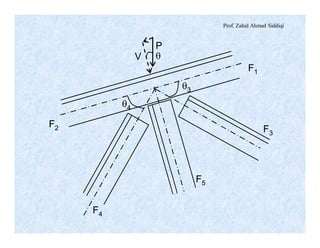

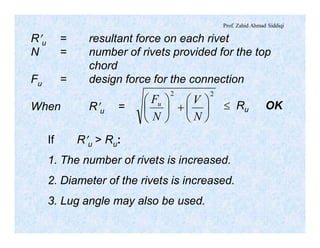

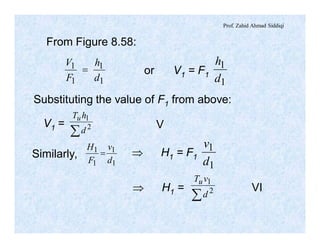

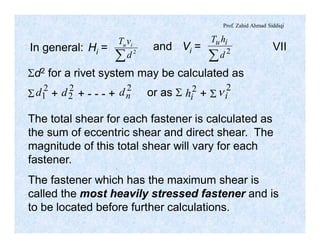

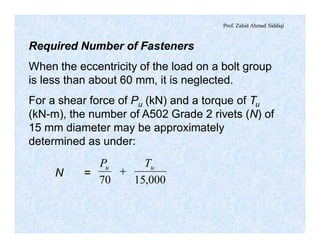

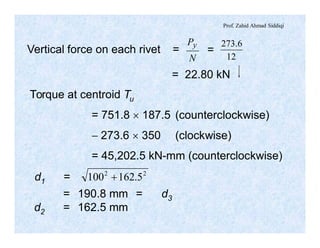

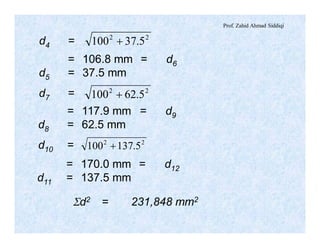

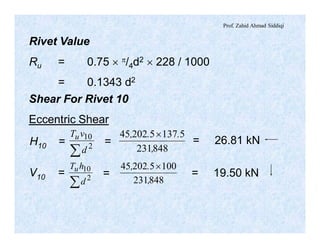

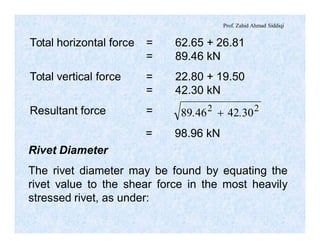

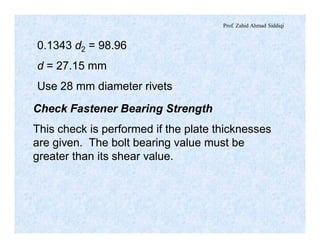

- Methods for calculating the load capacity ("rivet value") of single rivets in lap joints