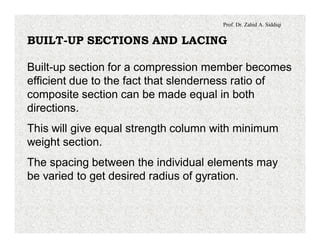

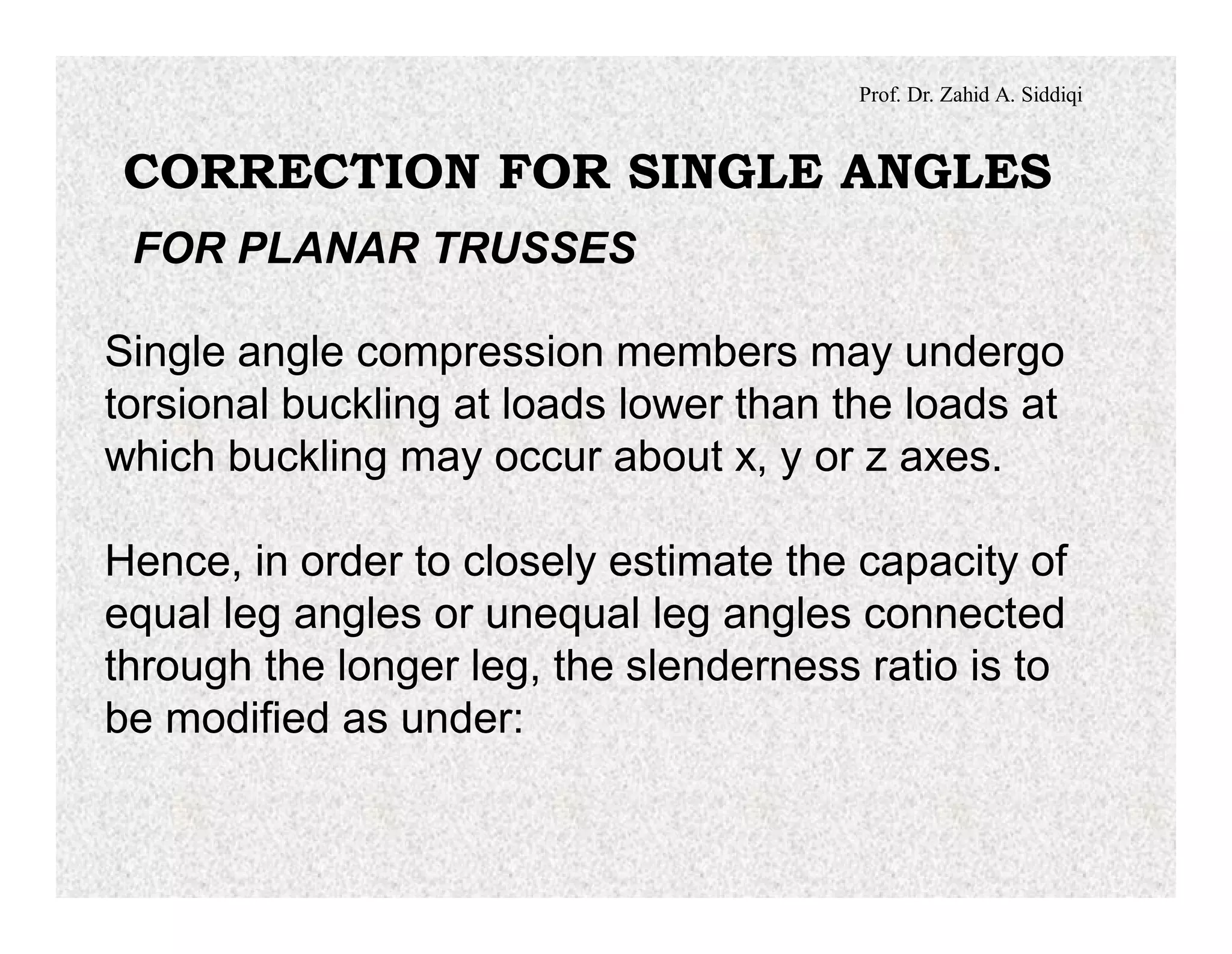

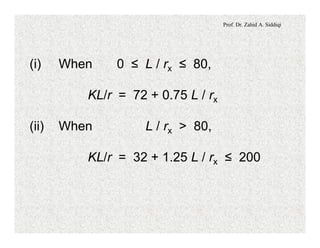

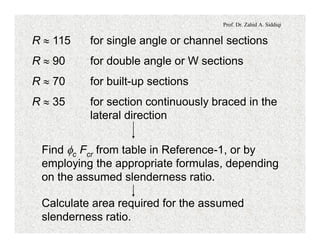

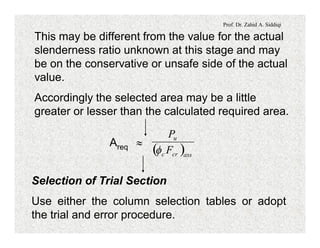

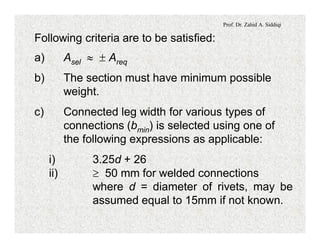

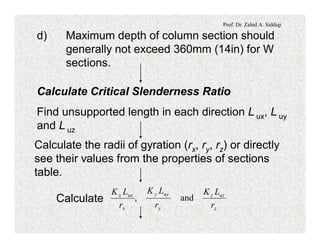

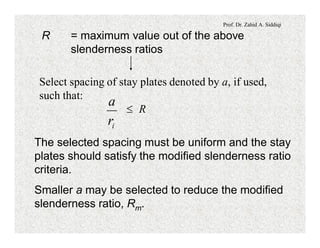

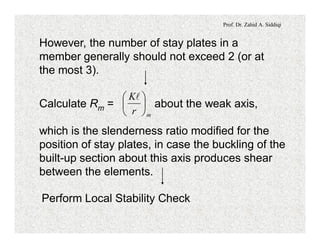

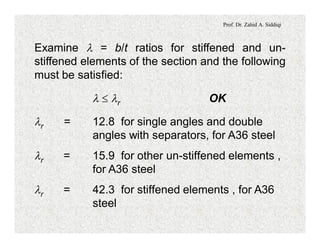

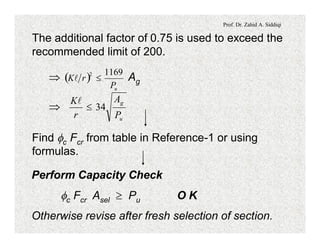

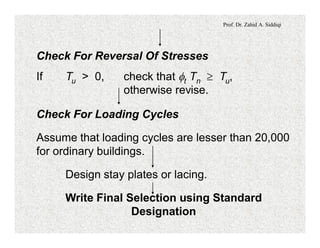

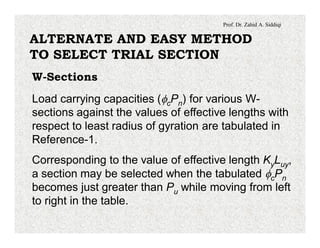

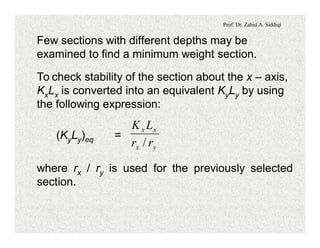

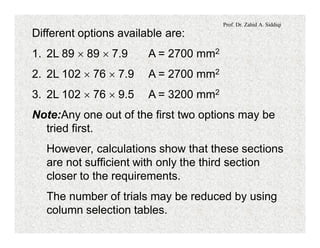

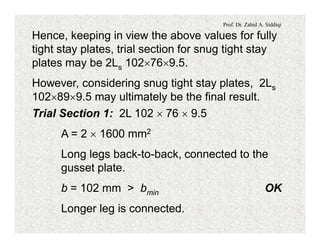

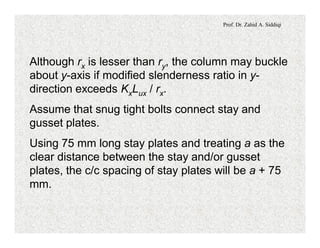

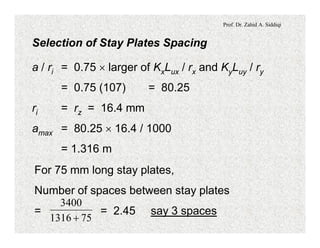

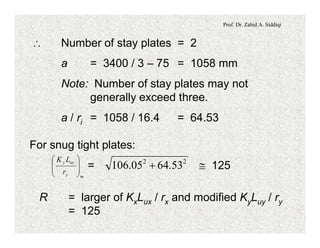

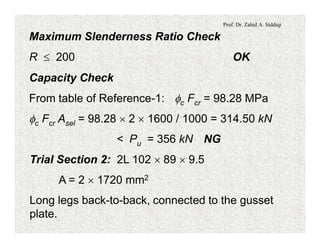

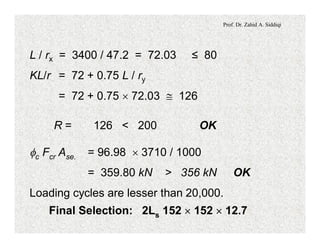

The document discusses the design of compression members in planar trusses. It provides modifications to the slenderness ratio that must be applied when designing single angle compression members to account for potential torsional buckling. It then outlines a design flow chart for selecting compression member sections, including calculating required member capacity and area, selecting a trial section, and performing various checks related to stability, slenderness ratio and member capacity. An alternate method for selecting W-sections or double angle sections using column selection tables is also described.

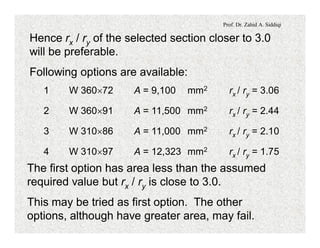

![Prof. Dr. Zahid A. Siddiqi

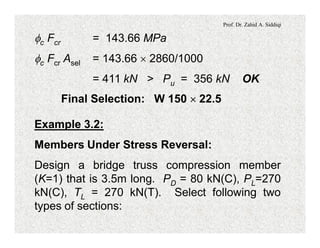

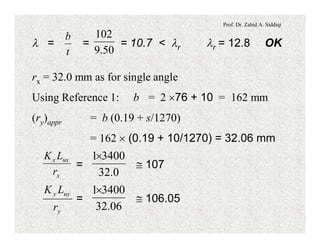

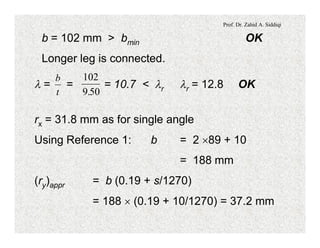

Exact calculations for ry (to be made only for the

last trial):

Iy = 2 ´ [123 ´ 104 + 1720 ´ (24.3 + 5)2]

= 541.3 ´ 104 mm4

(ry)exact = = 39.7 mm

17202

103.541 4

´

´

= @ 107

x

uxx

r

LK

8.31

34001´

= @ 85.64

y

uyy

r

LK

7.39

34001´](https://image.slidesharecdn.com/steelstrucurelec7-200810021452/85/Steel-strucure-lec-7-33-320.jpg)

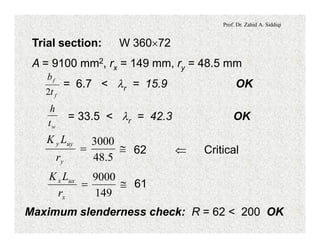

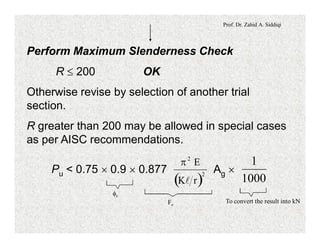

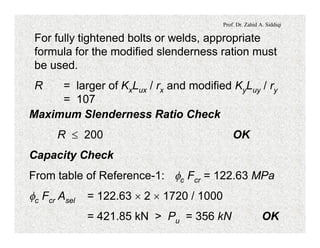

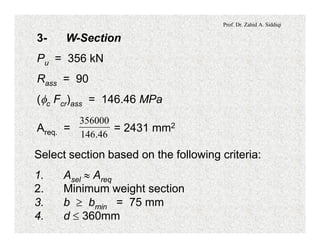

![Prof. Dr. Zahid A. Siddiqi

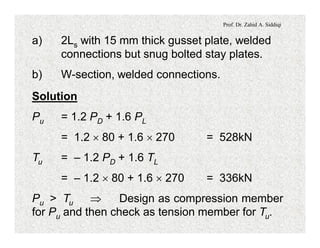

Using the W-shape selection tables of Reference-1

for Pu = 356 kN, KyLy = 3.4m, following option is

obtained [(KyLy)eq is not critical]:

Trial Section: W150 ´ 22.5

rx = 65 ; ry = 37.1 ; A = 2860 mm2

bf / 2 = 152 / 2 = 76 mm > bmin OK

l = = 11.5 < lr = 15.9 OK

f

f

t

b

2

l = = 21.6 < lr = 42.3 OK

wt

h

R = = @ 92 < 200 OK

.minr

Kl

1.37

3400](https://image.slidesharecdn.com/steelstrucurelec7-200810021452/85/Steel-strucure-lec-7-42-320.jpg)