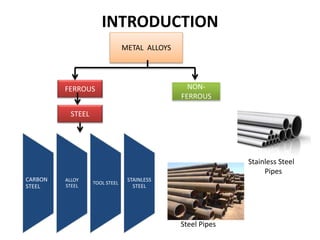

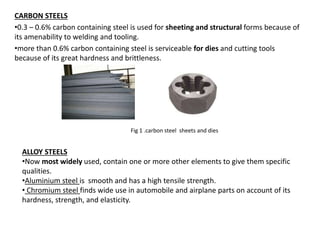

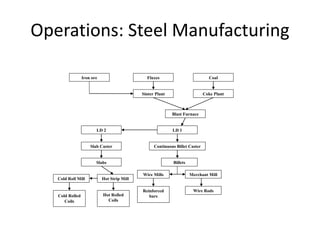

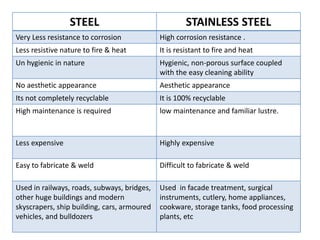

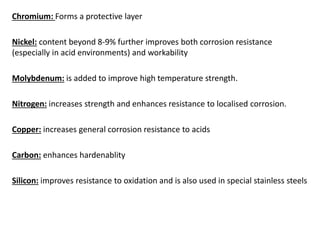

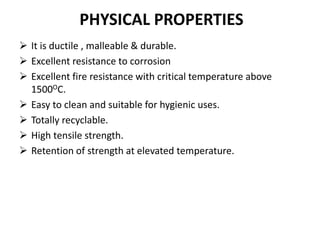

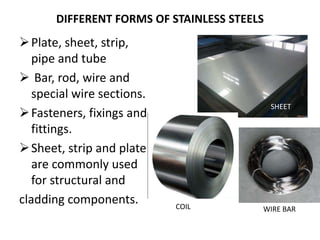

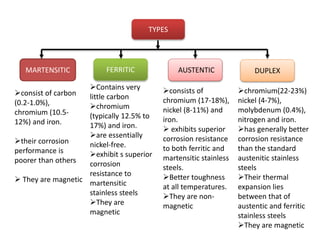

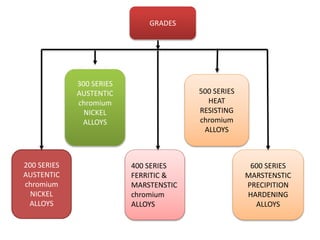

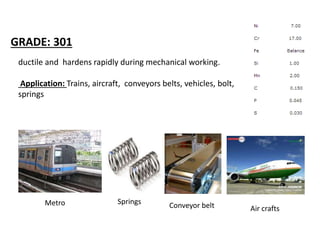

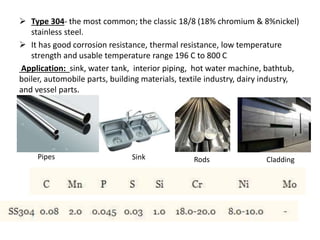

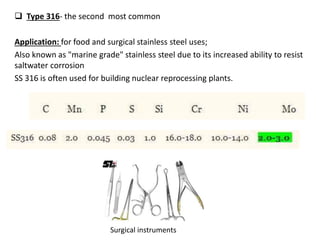

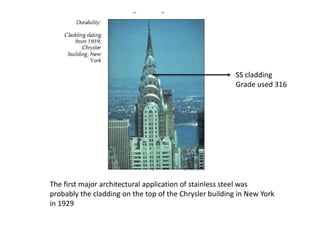

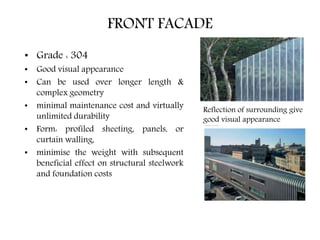

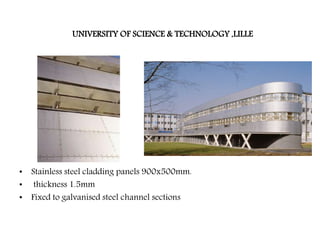

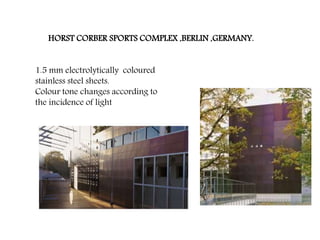

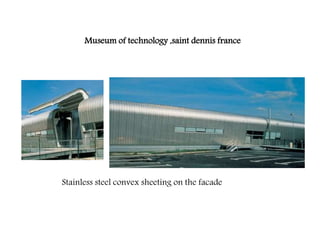

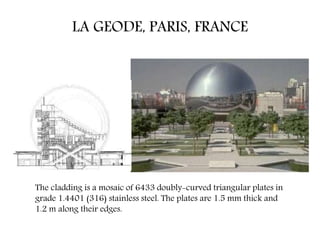

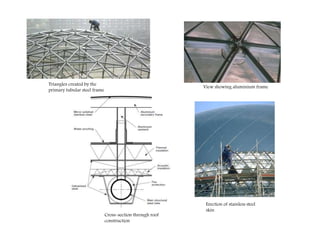

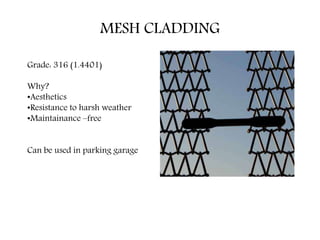

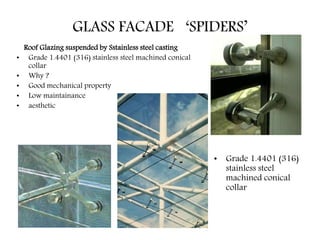

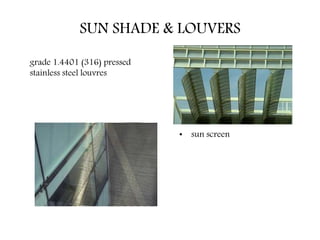

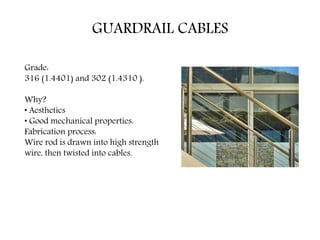

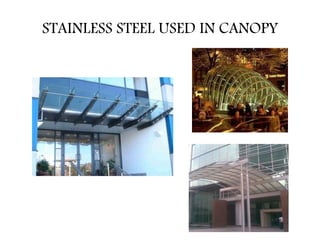

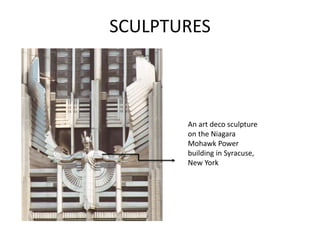

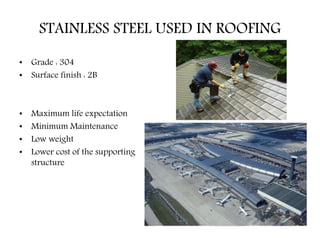

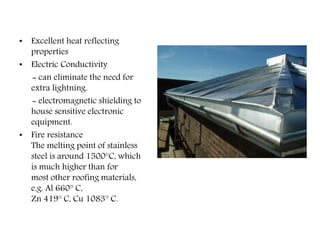

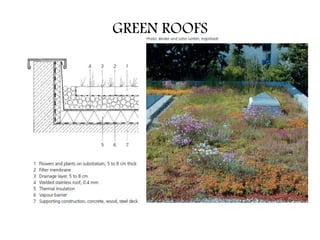

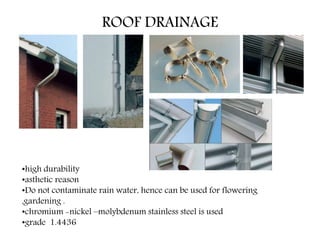

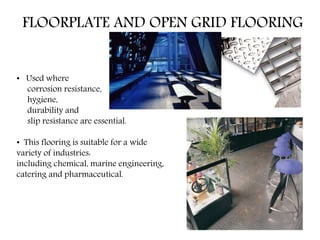

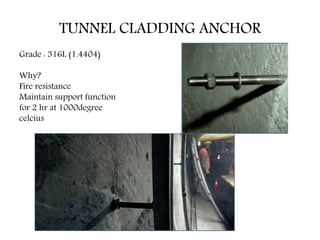

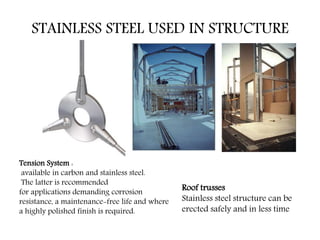

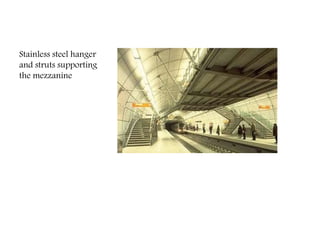

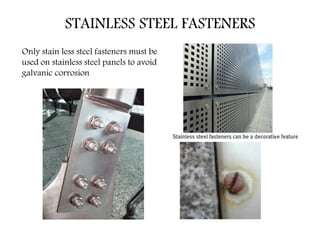

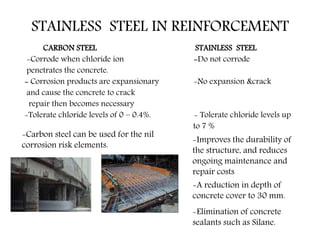

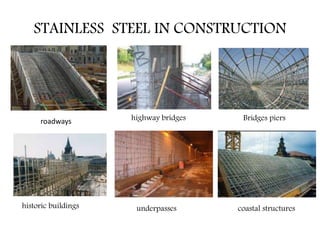

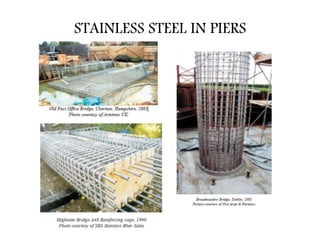

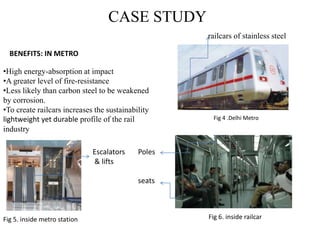

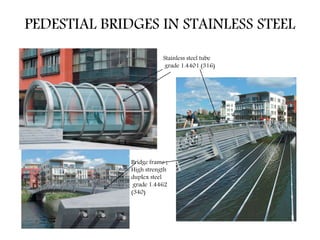

This document provides information on steel and stainless steel. It discusses the composition of steel as an alloy of iron and carbon, and stainless steel as containing a minimum of 10.5% chromium. It describes the properties and applications of different types and grades of steel and stainless steel, including in construction materials, appliances, transportation, infrastructure, and more. It also discusses the manufacturing process for steel and provides examples of architectural and structural uses of stainless steel.