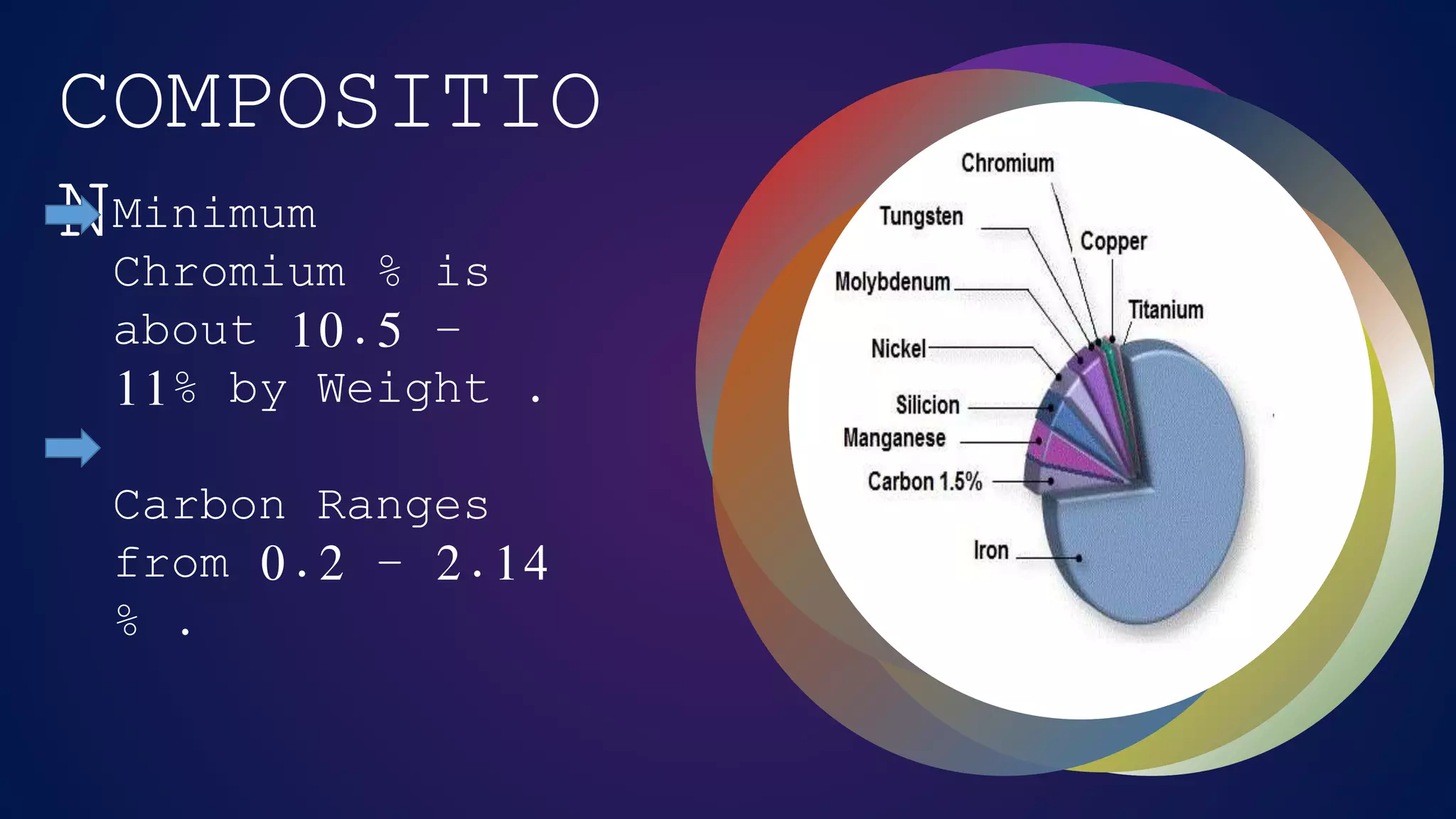

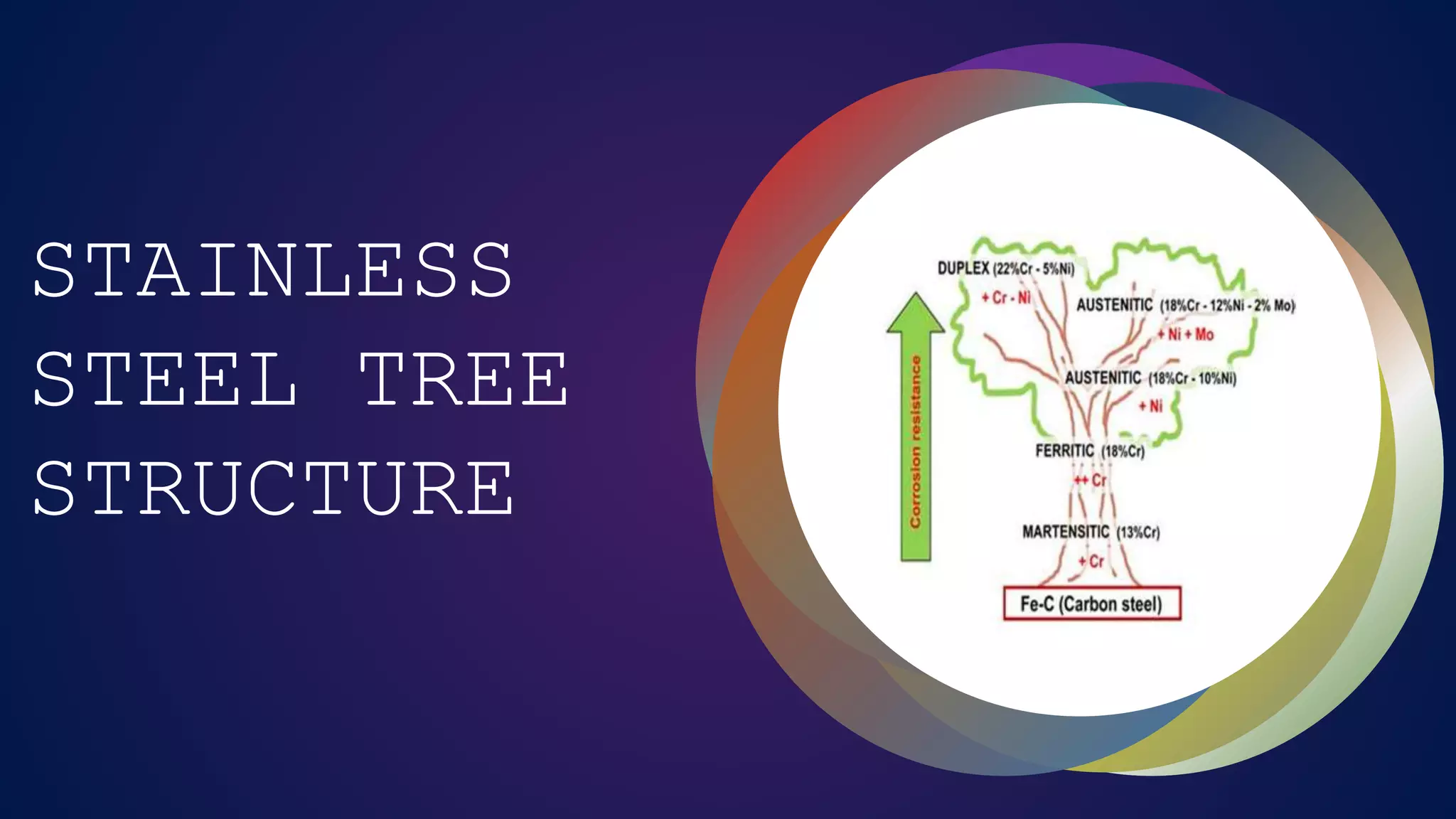

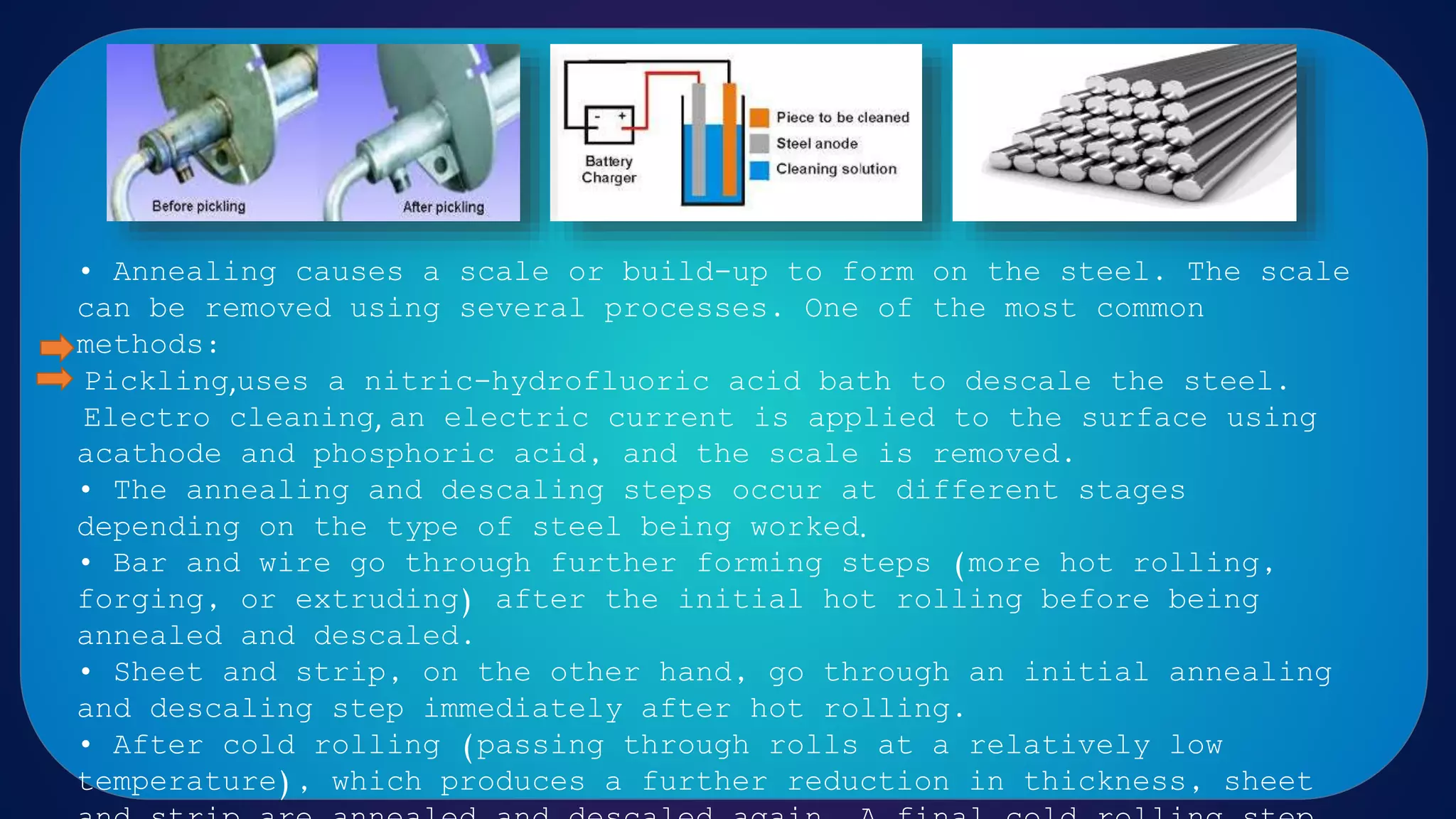

Stainless steel is an alloy of iron, chromium, and sometimes nickel that is known for its corrosion resistance and strength. It requires a minimum of 10.5-11% chromium content to give it good corrosion resistance through the formation of a passive chromium oxide layer. There are several types of stainless steel including austenitic, ferritic, martensitic, duplex, and precipitation hardening grades, each with different microstructures and properties. Stainless steel finds wide application in industries such as medical, chemical processing, marine, and automotive due to its corrosion resistance.