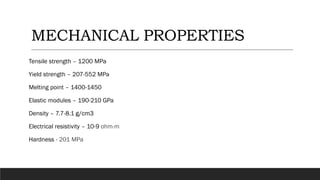

The document provides an in-depth overview of stainless steel, covering its manufacturing processes, properties, types, and applications. It details various grades such as ferritic, austenitic, martensitic, and duplex stainless steels, highlighting their respective advantages, disadvantages, and specific uses in industries such as construction and manufacturing. Additionally, the document includes a market survey with references to suppliers and industry standards.