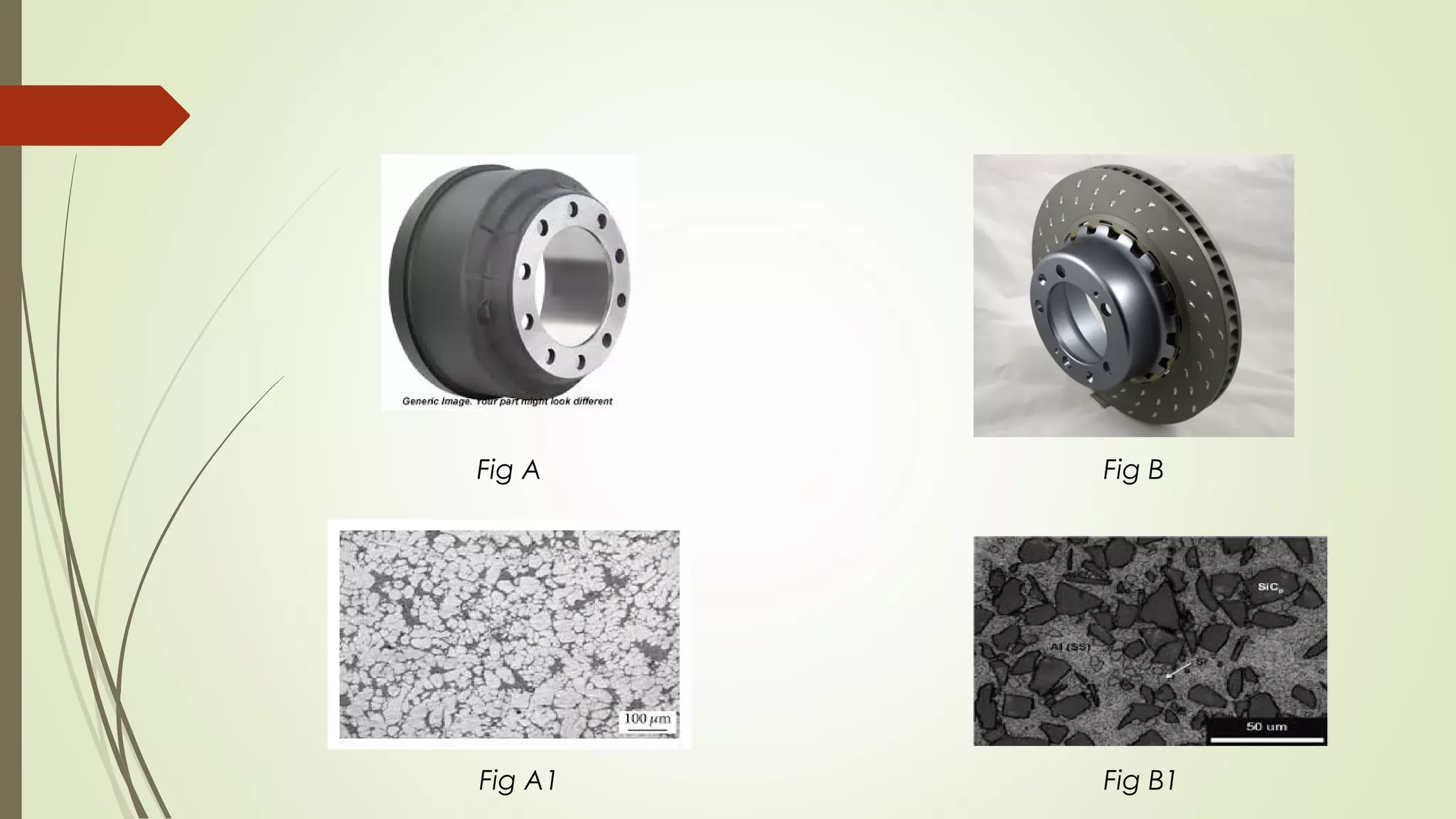

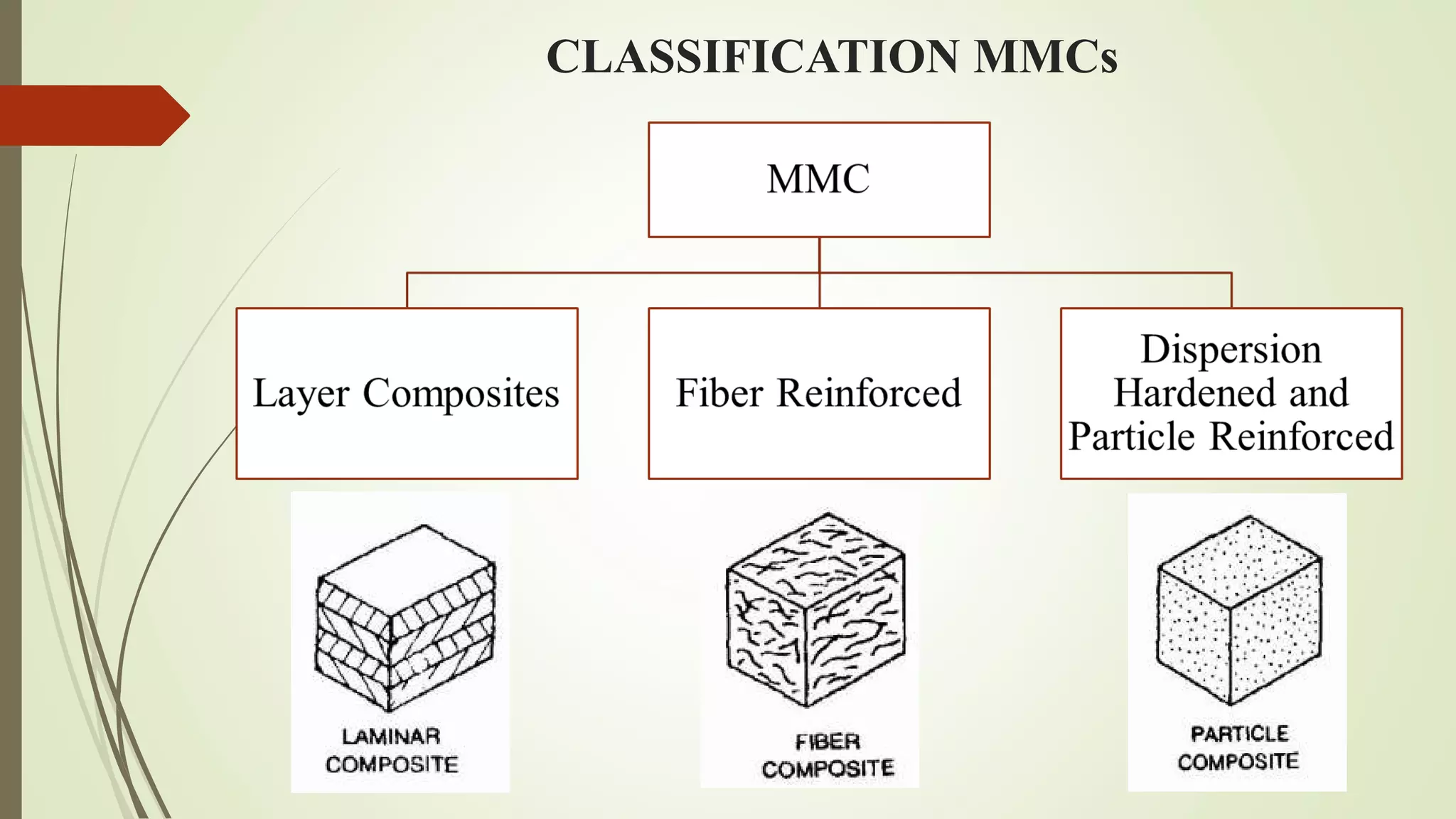

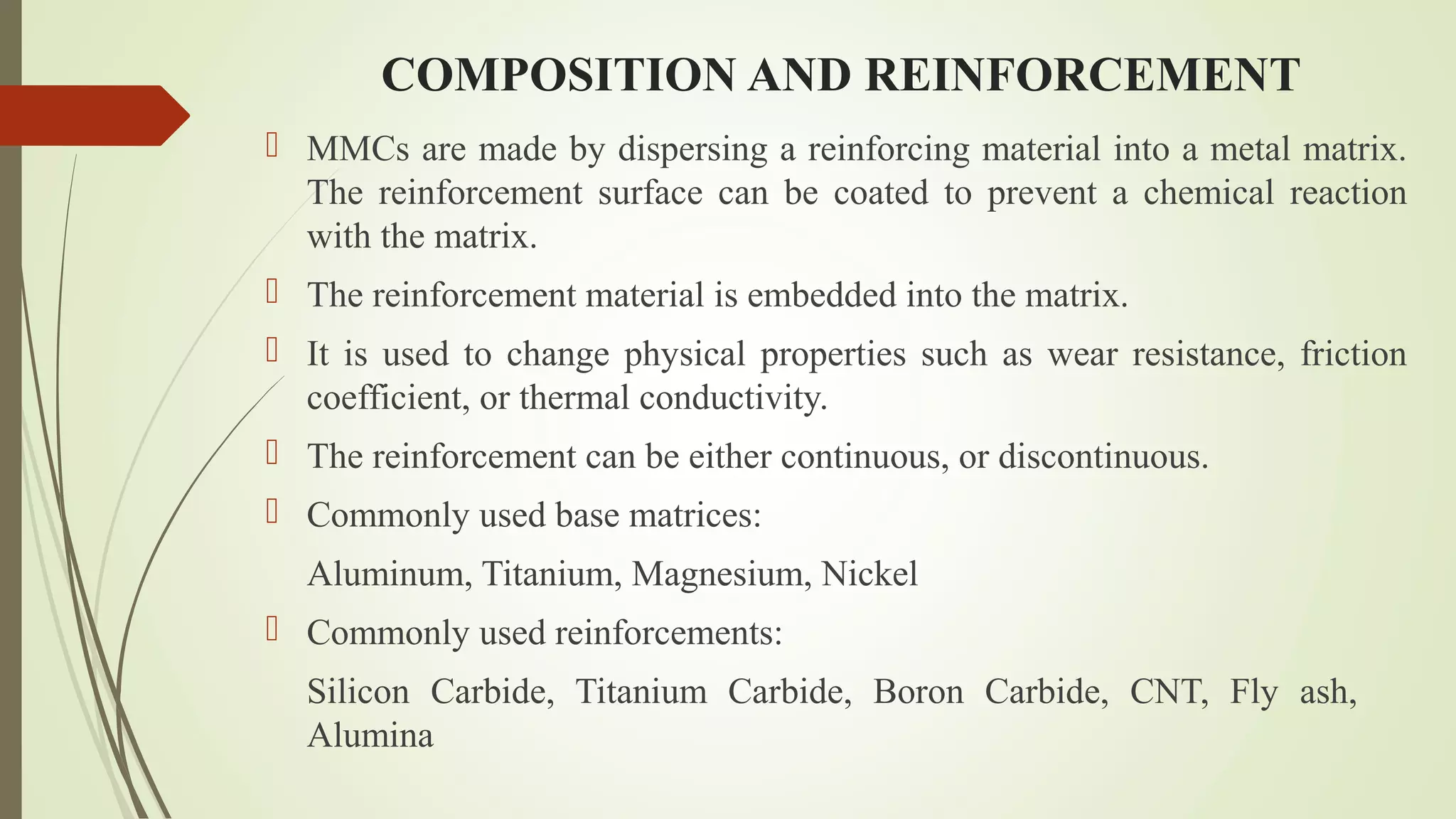

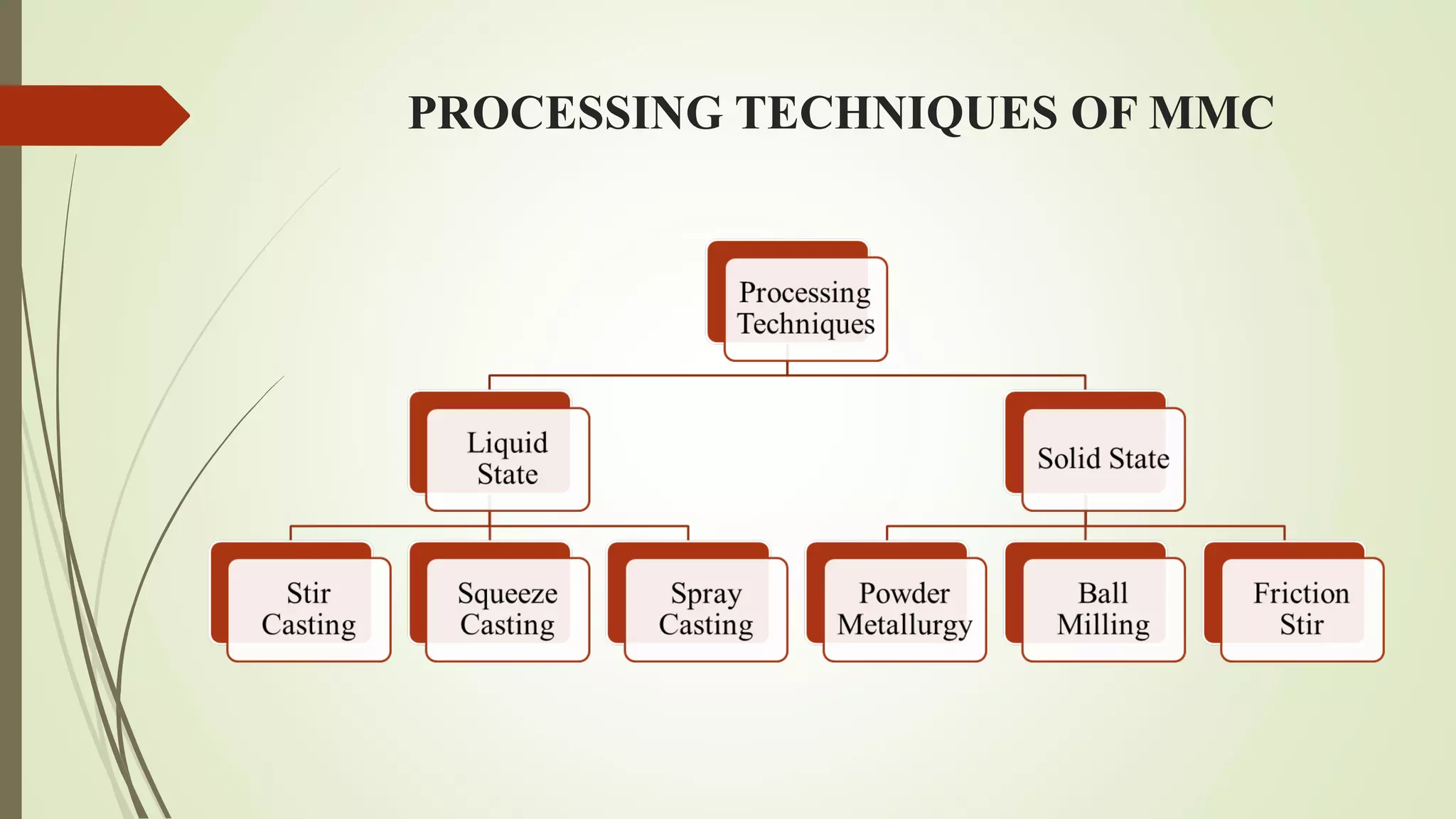

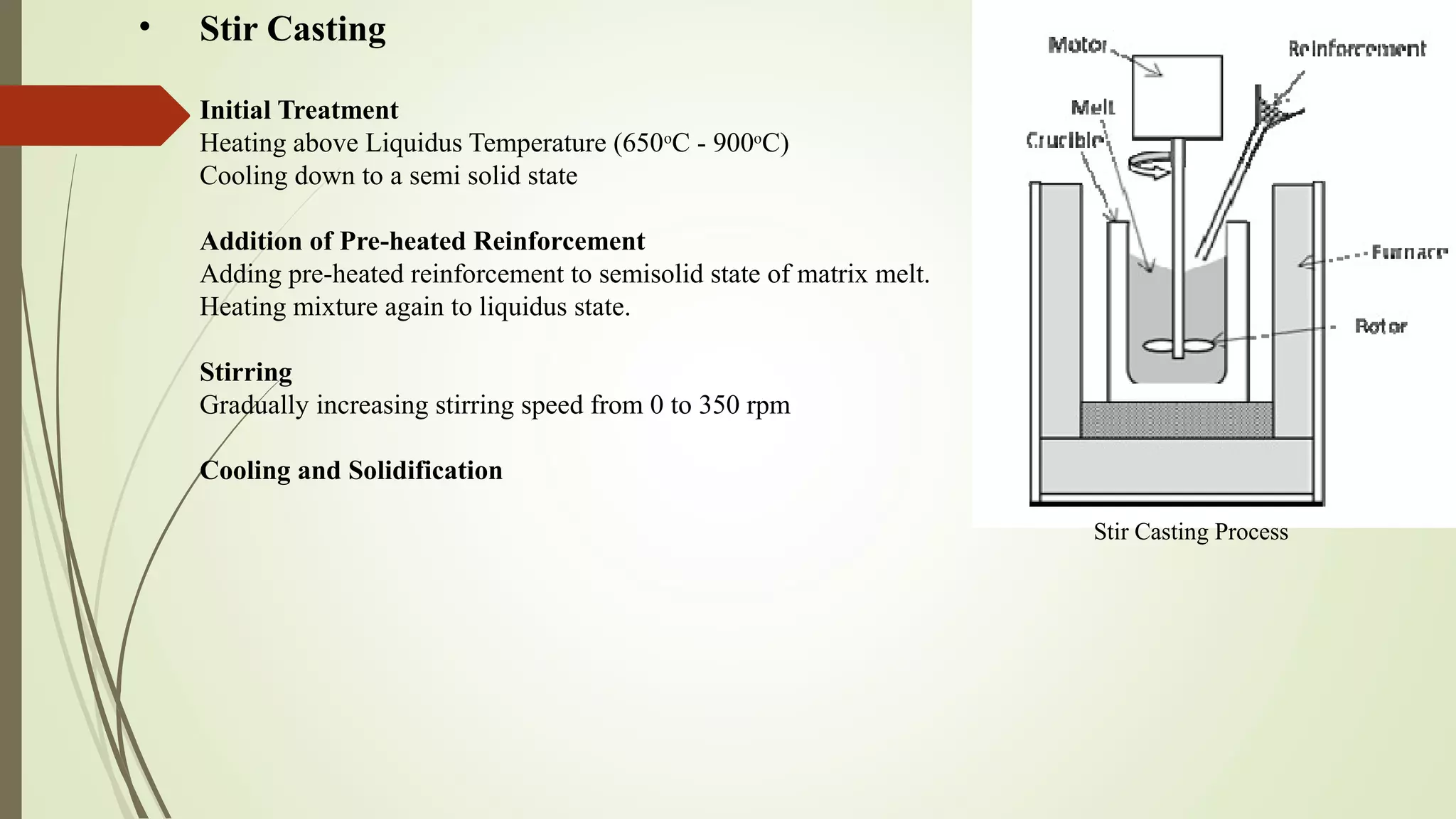

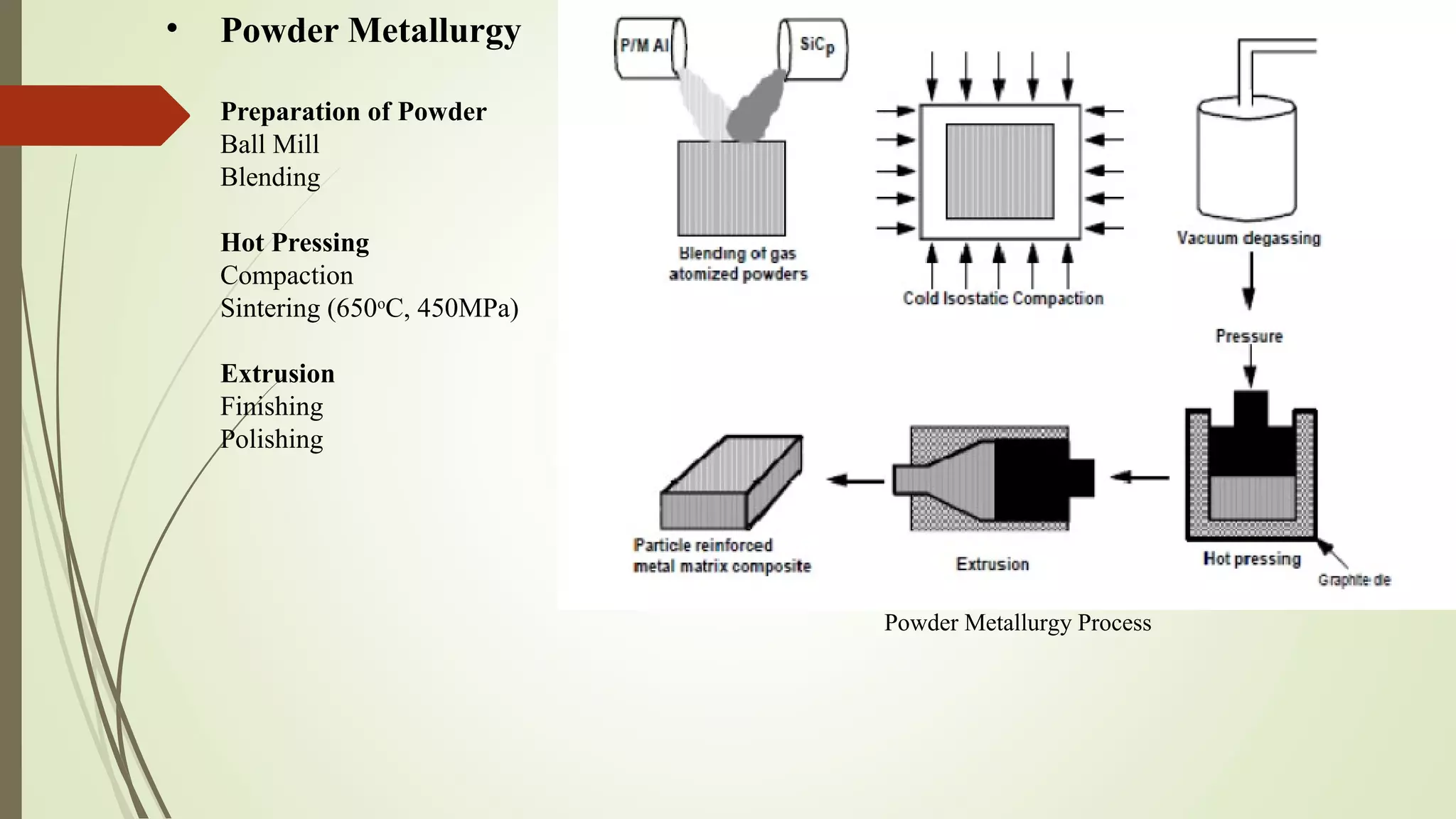

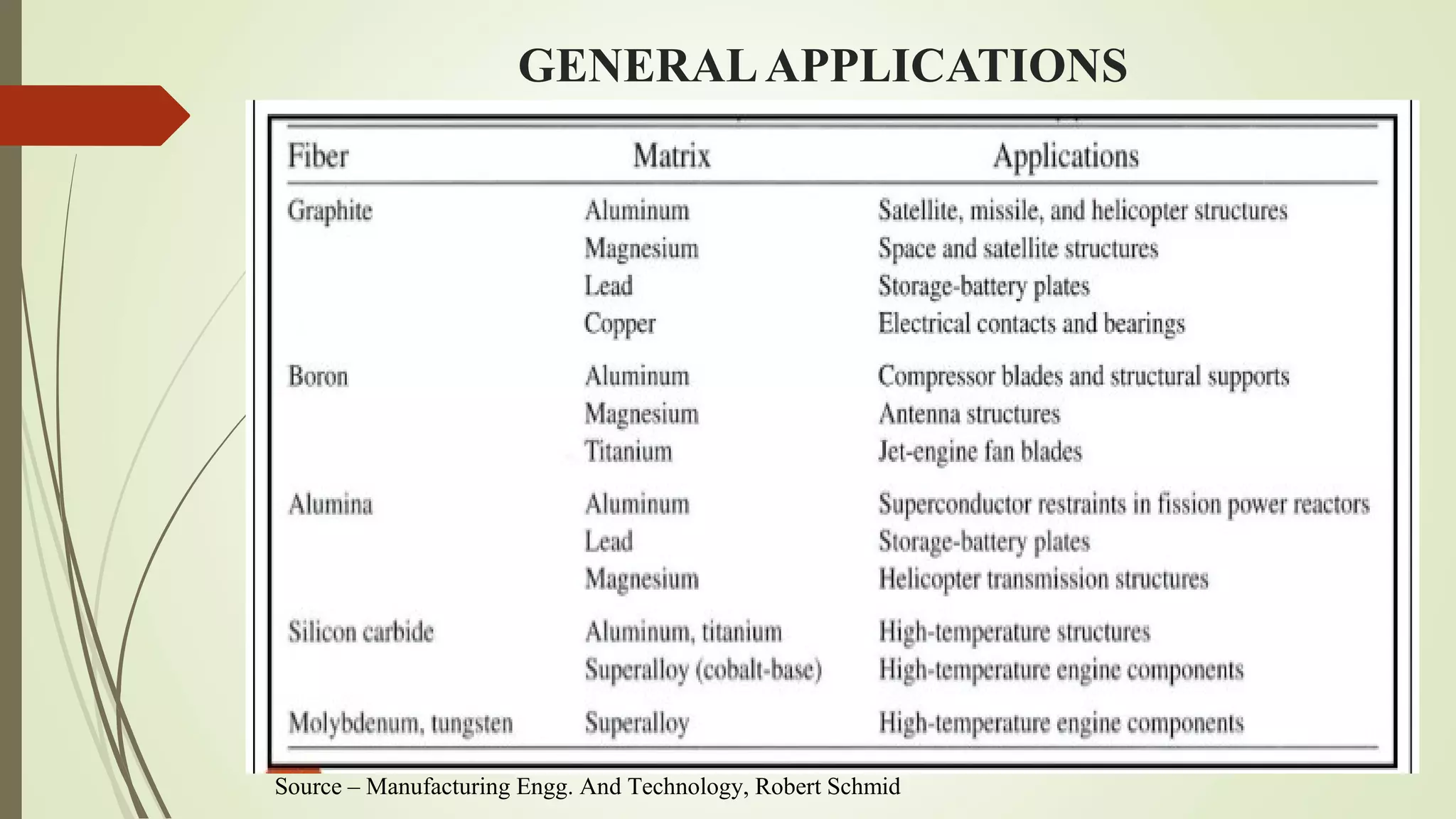

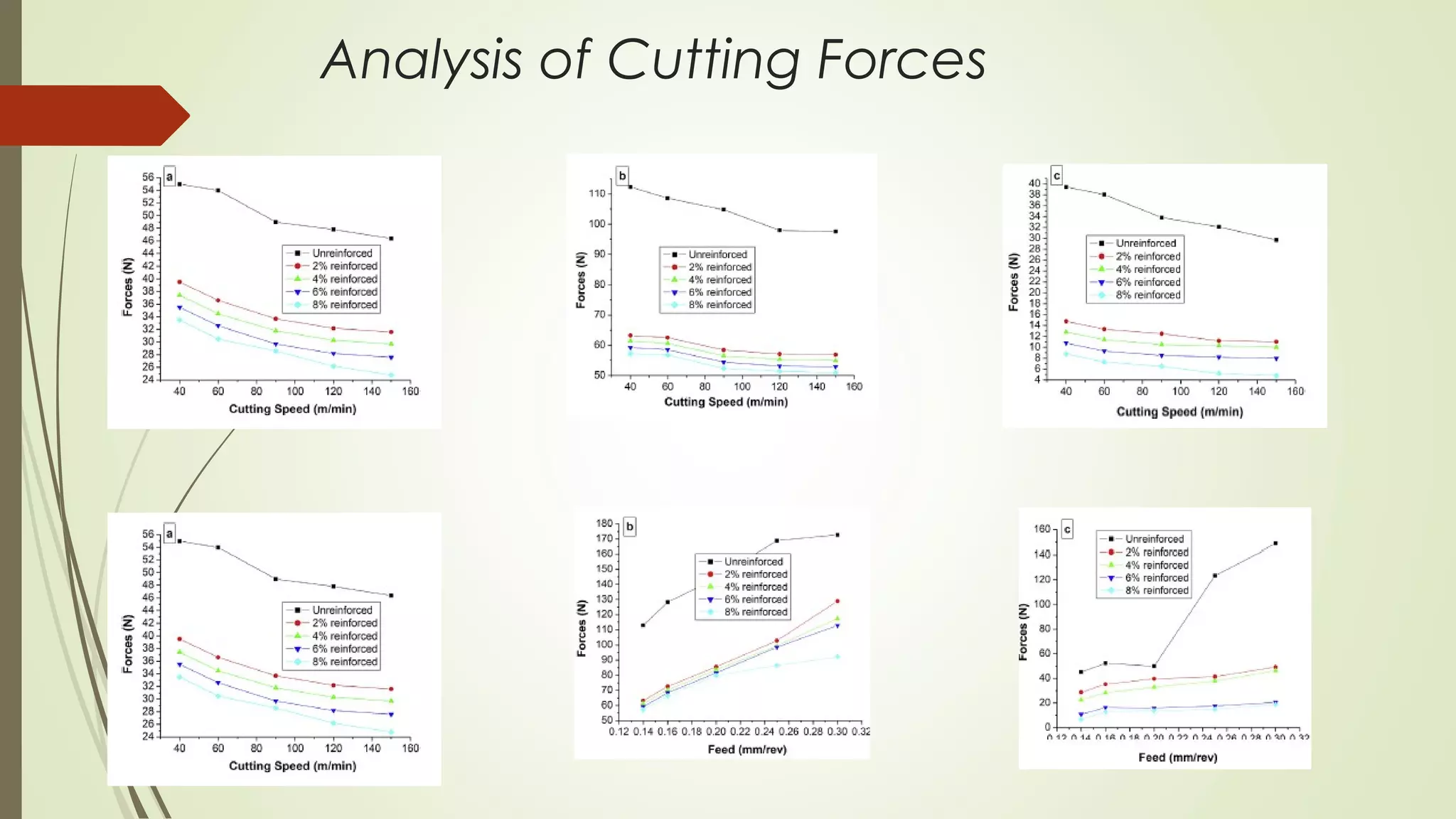

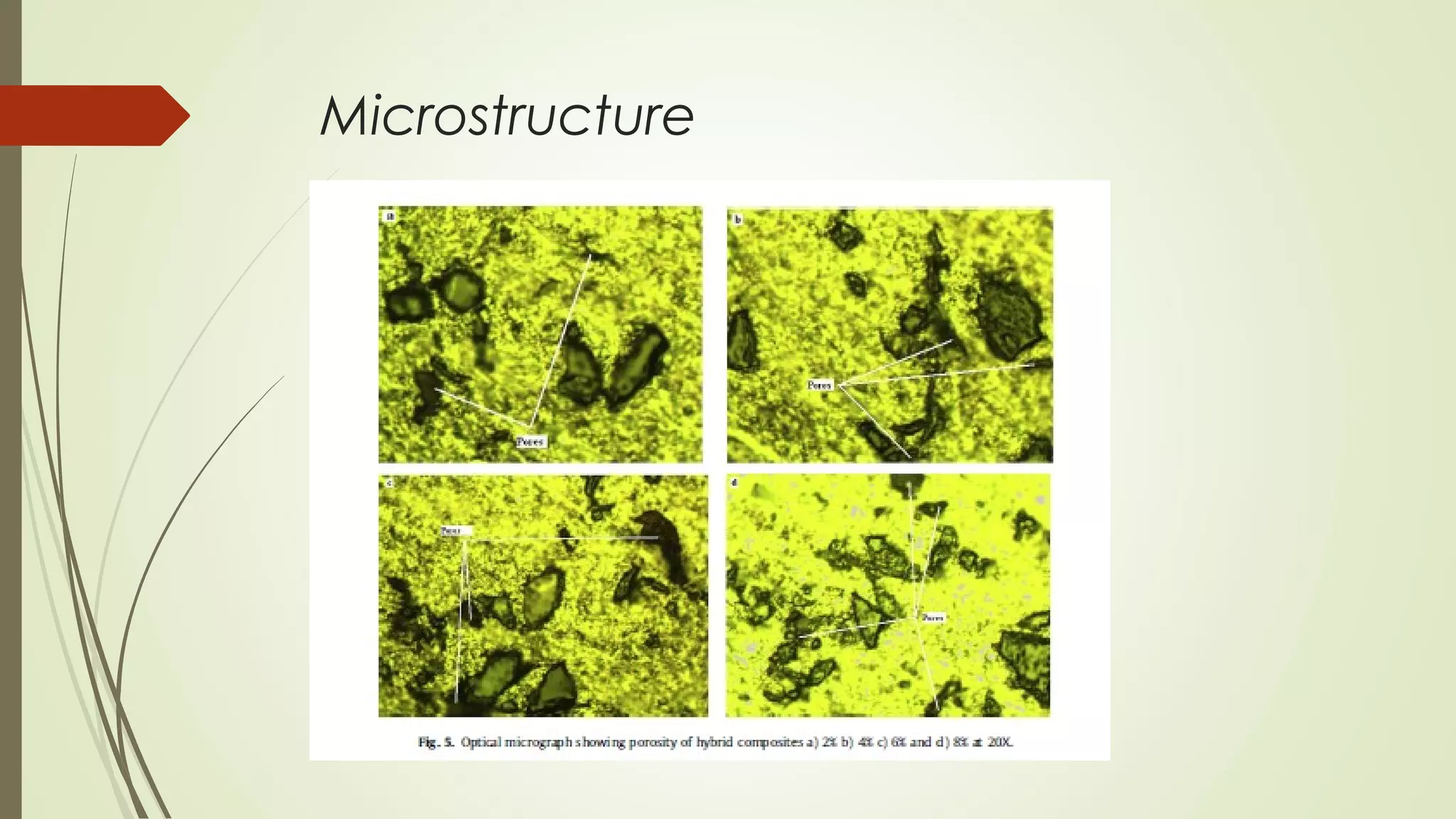

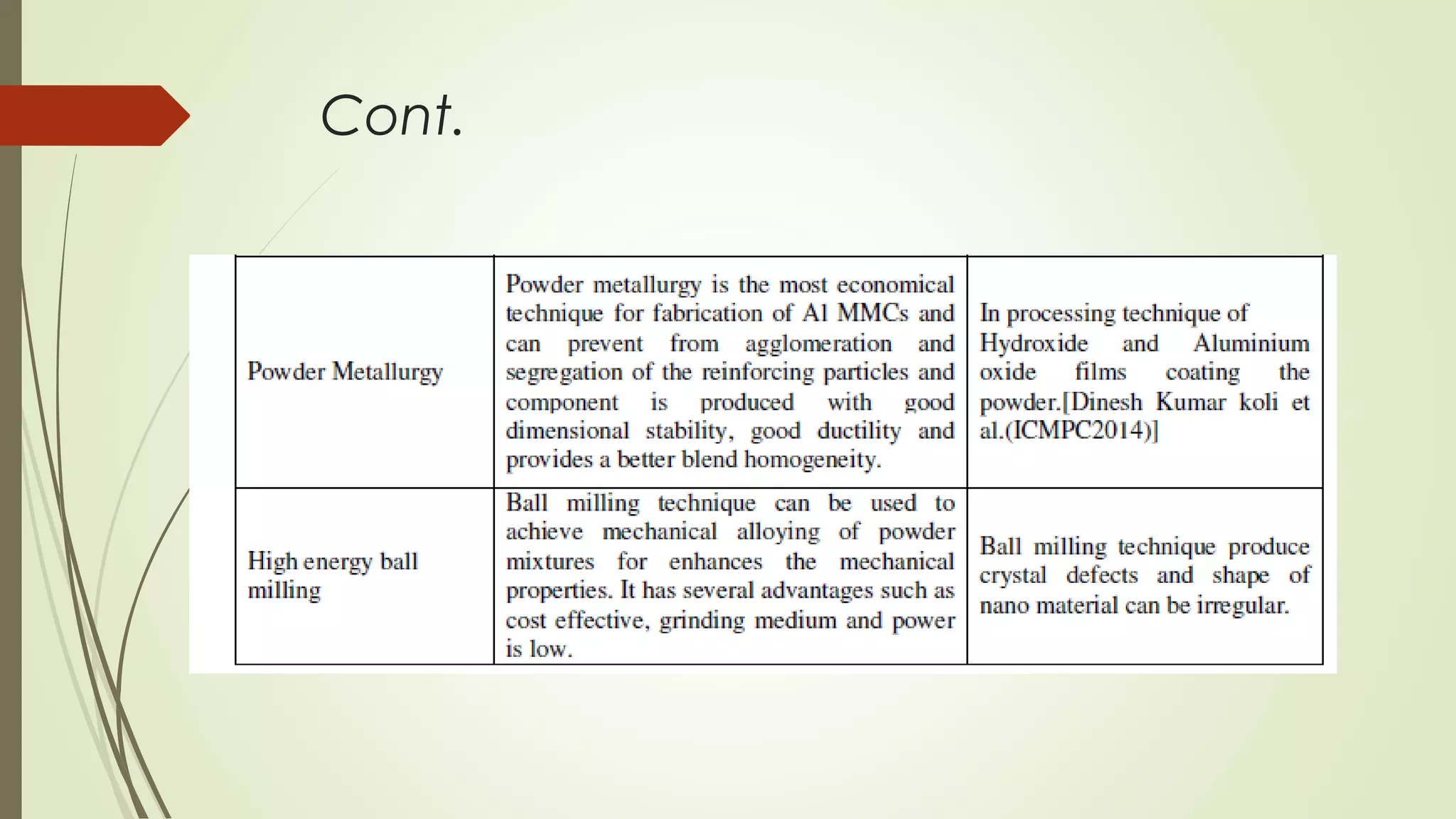

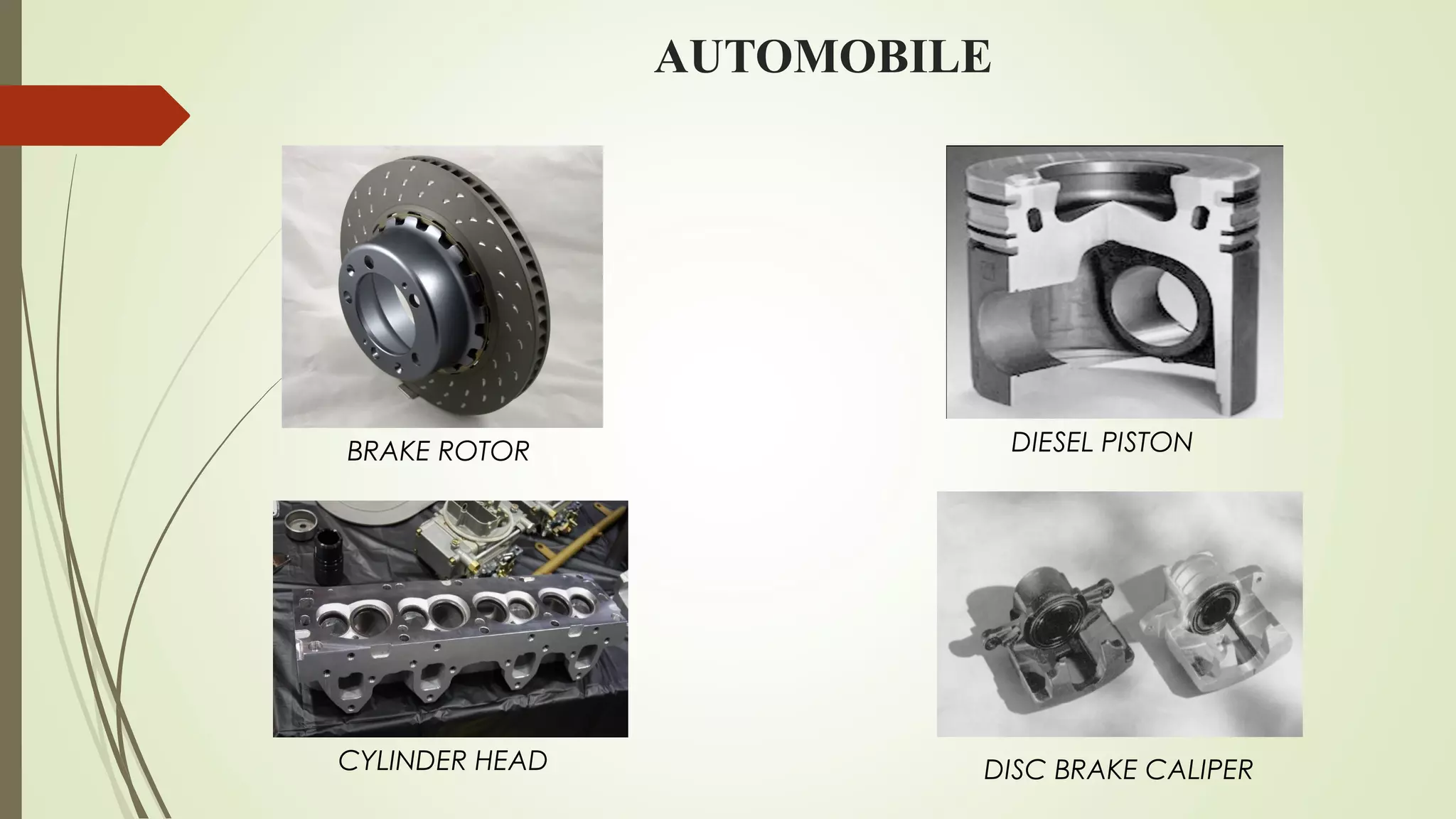

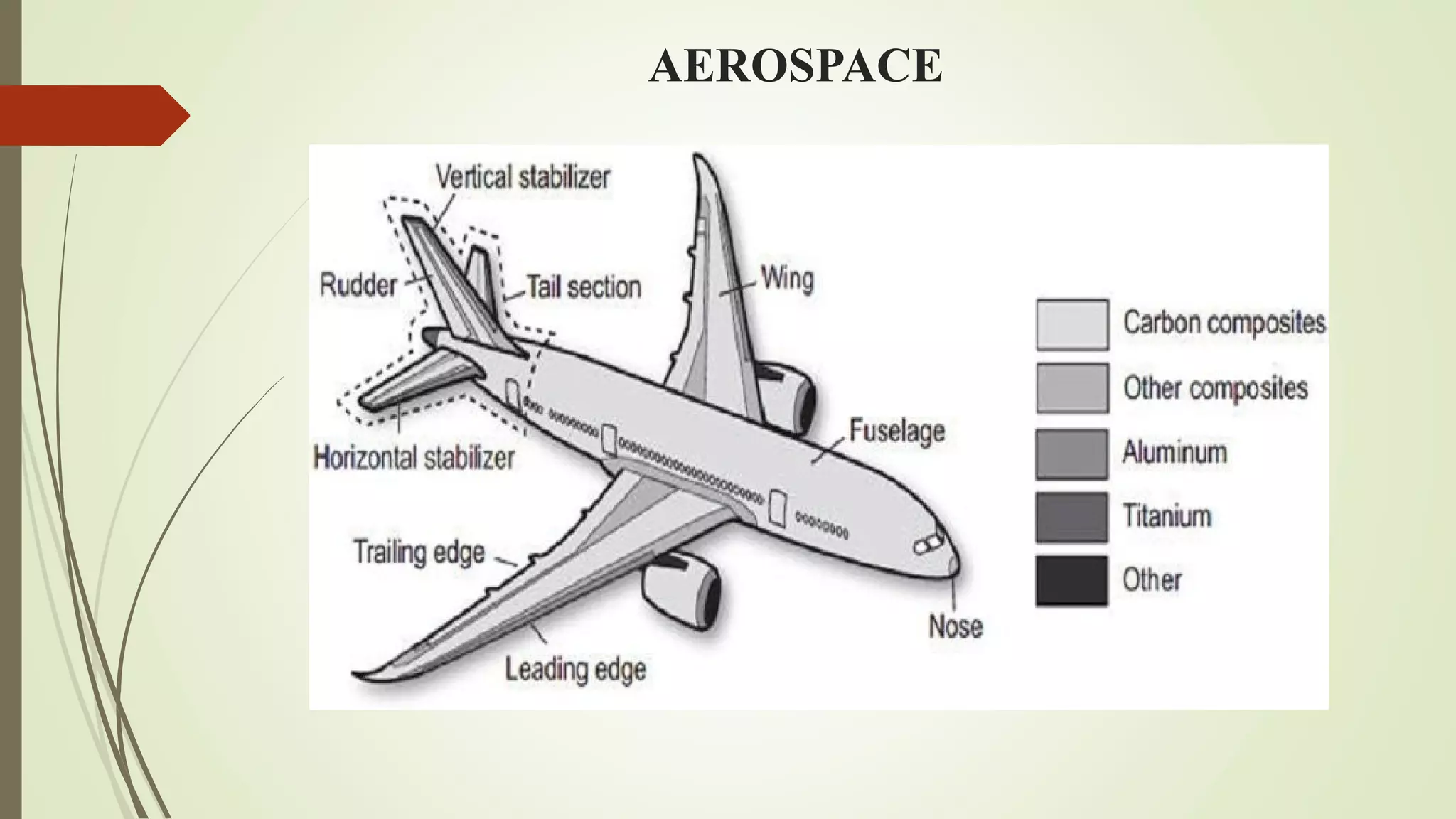

This document discusses metal matrix composites (MMCs), which are composite materials with at least two constituent parts including a metal. MMCs can be classified based on their composition and reinforcement materials. Common reinforcement materials include silicon carbide, titanium carbide, and carbon nanotubes. Production methods for MMCs include stir casting and powder metallurgy. MMCs exhibit improved properties over unreinforced metals like high strength and stiffness. Applications of MMCs span aerospace, automotive, and other industries. The document outlines advantages like heat resistance and disadvantages like higher cost compared to unreinforced metals.