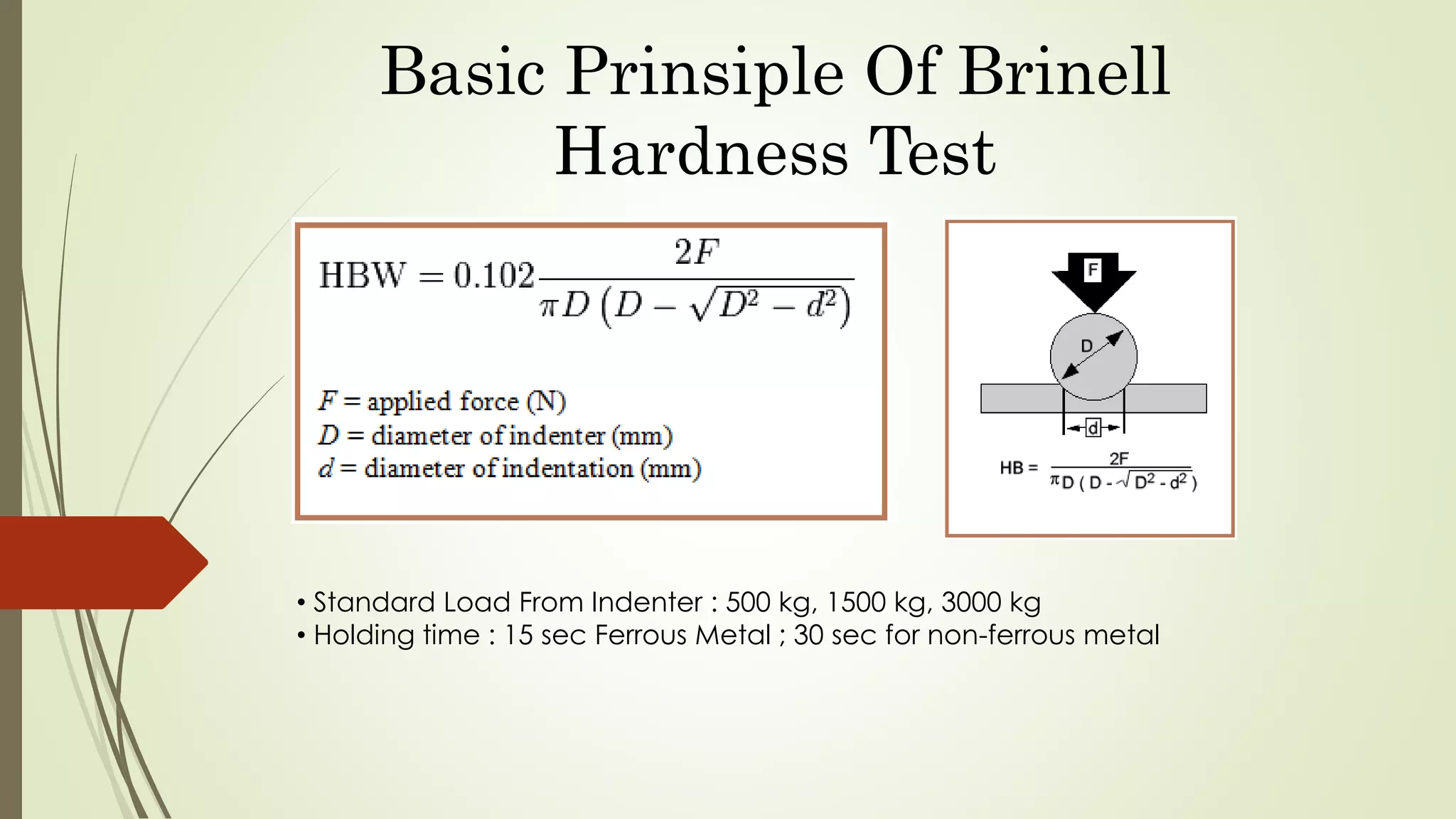

The document discusses two common hardness tests: the Brinell hardness test and the Rockwell hardness test. The Brinell hardness test uses a spherical indenter that is pressed into the material under a load. The size of the indentation is then measured and correlated to a Brinell hardness number. The Rockwell hardness test uses different indenters and loads depending on the scale being used. It measures the increase in depth of an indentation to determine the Rockwell hardness number. Both tests provide a measure of a material's resistance to plastic deformation and can indicate its wear properties.