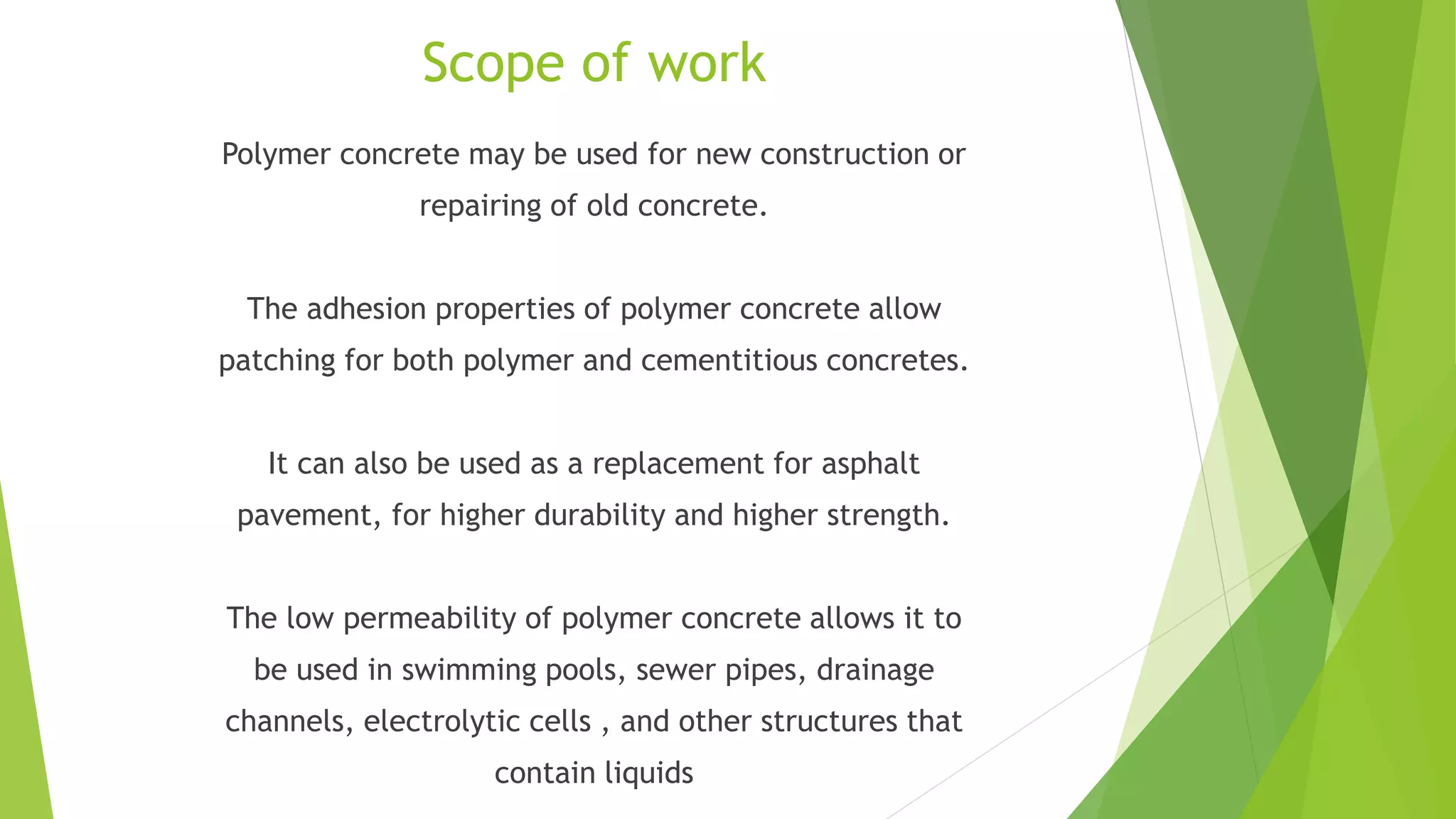

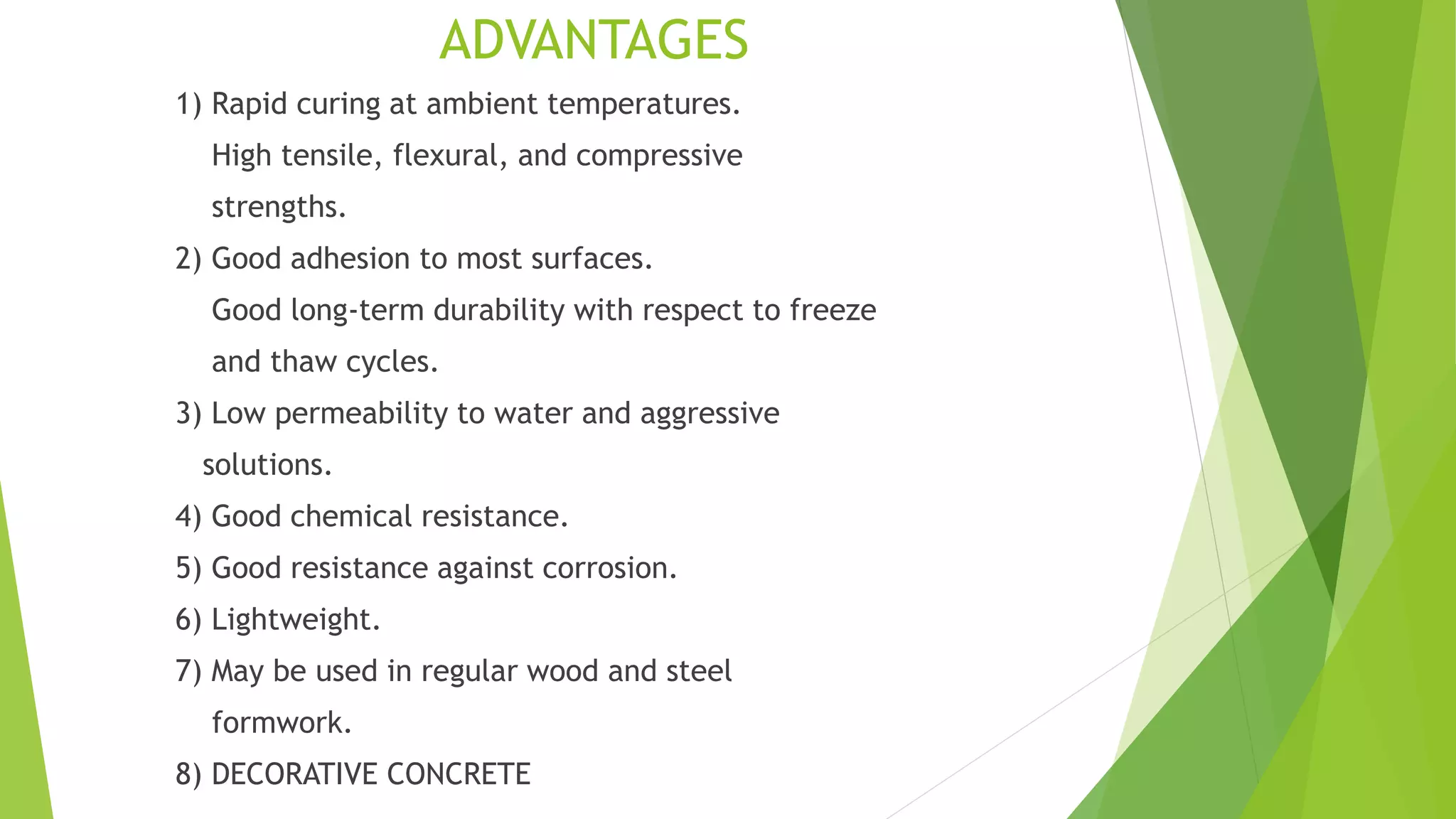

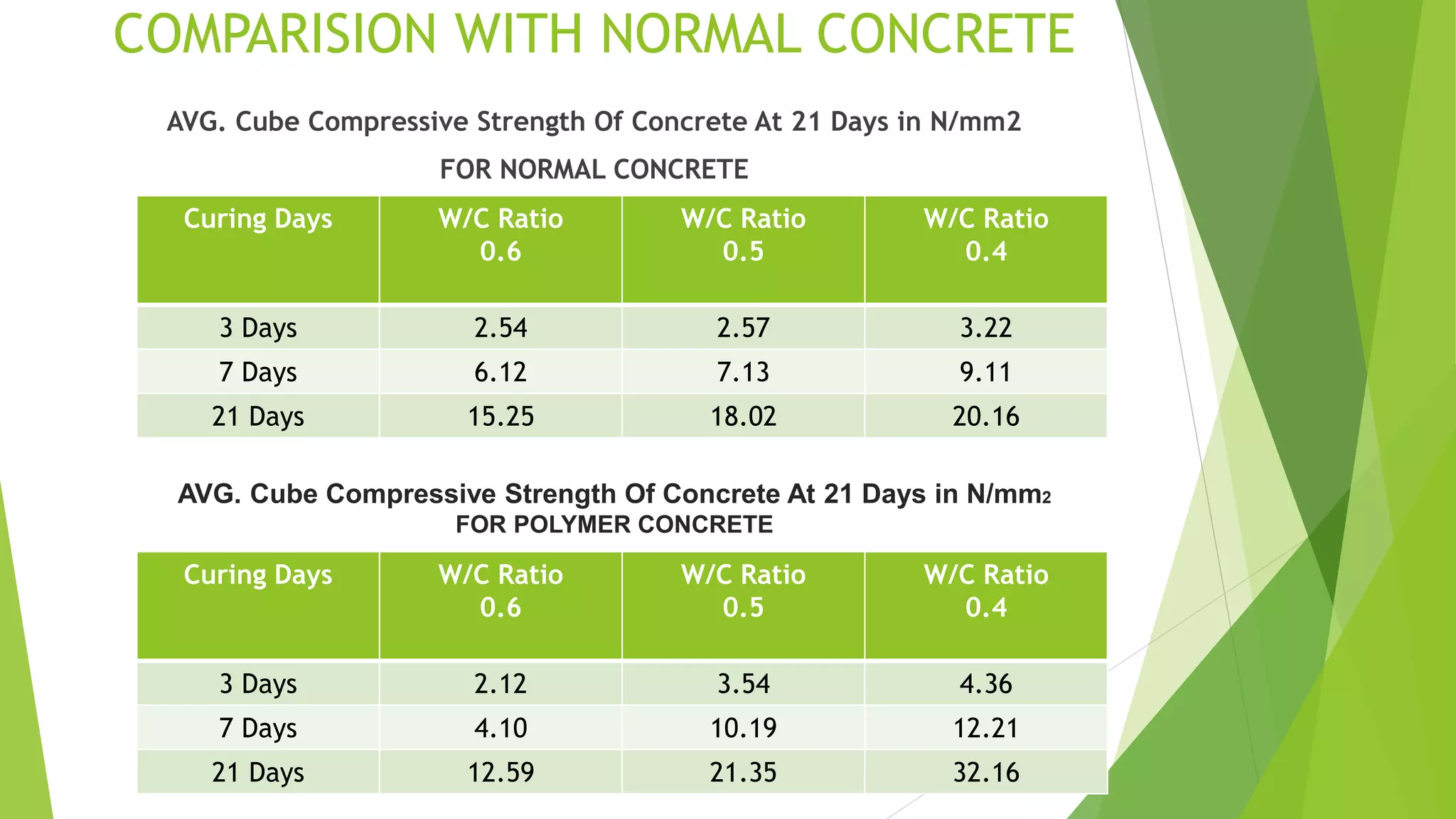

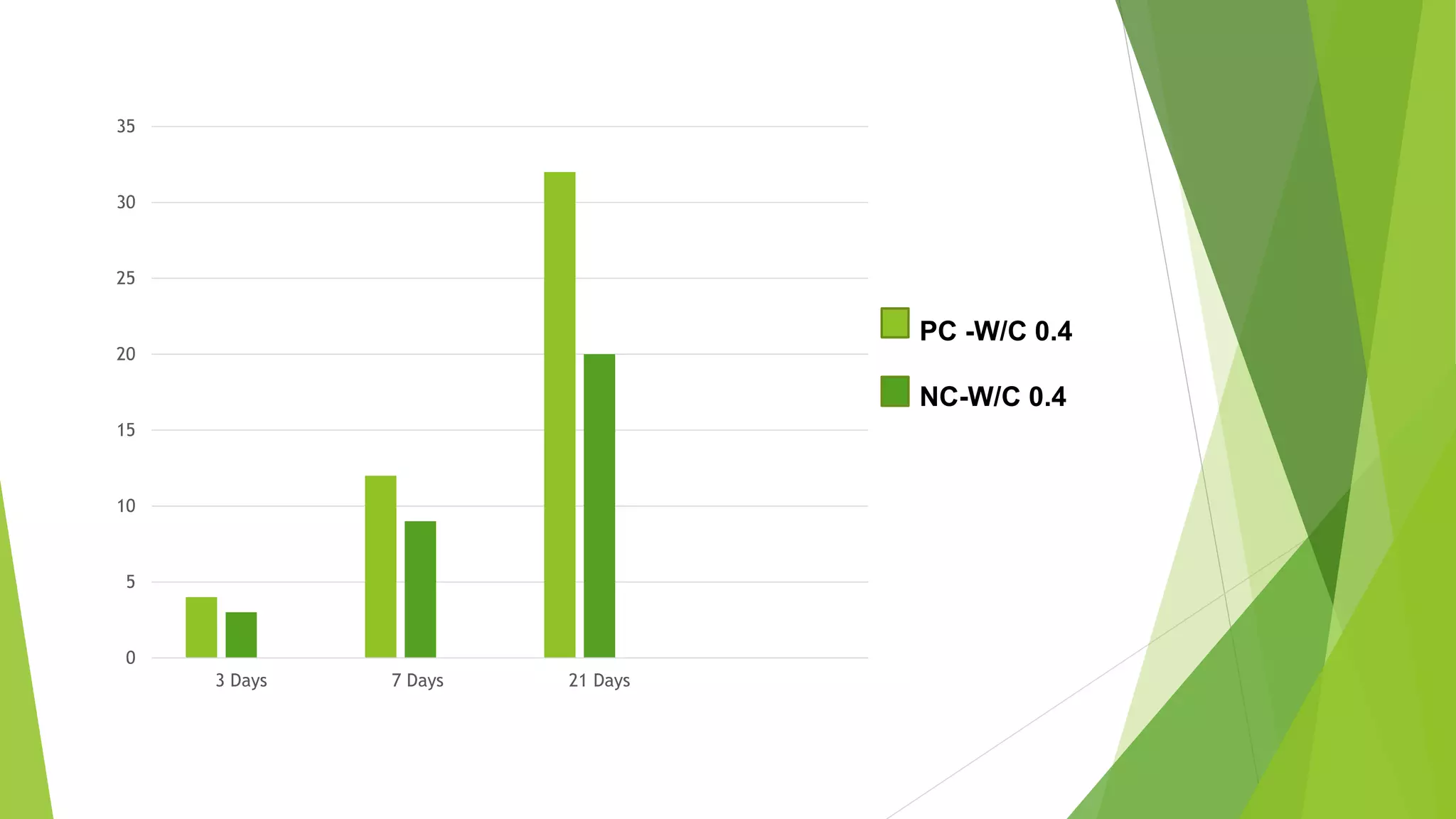

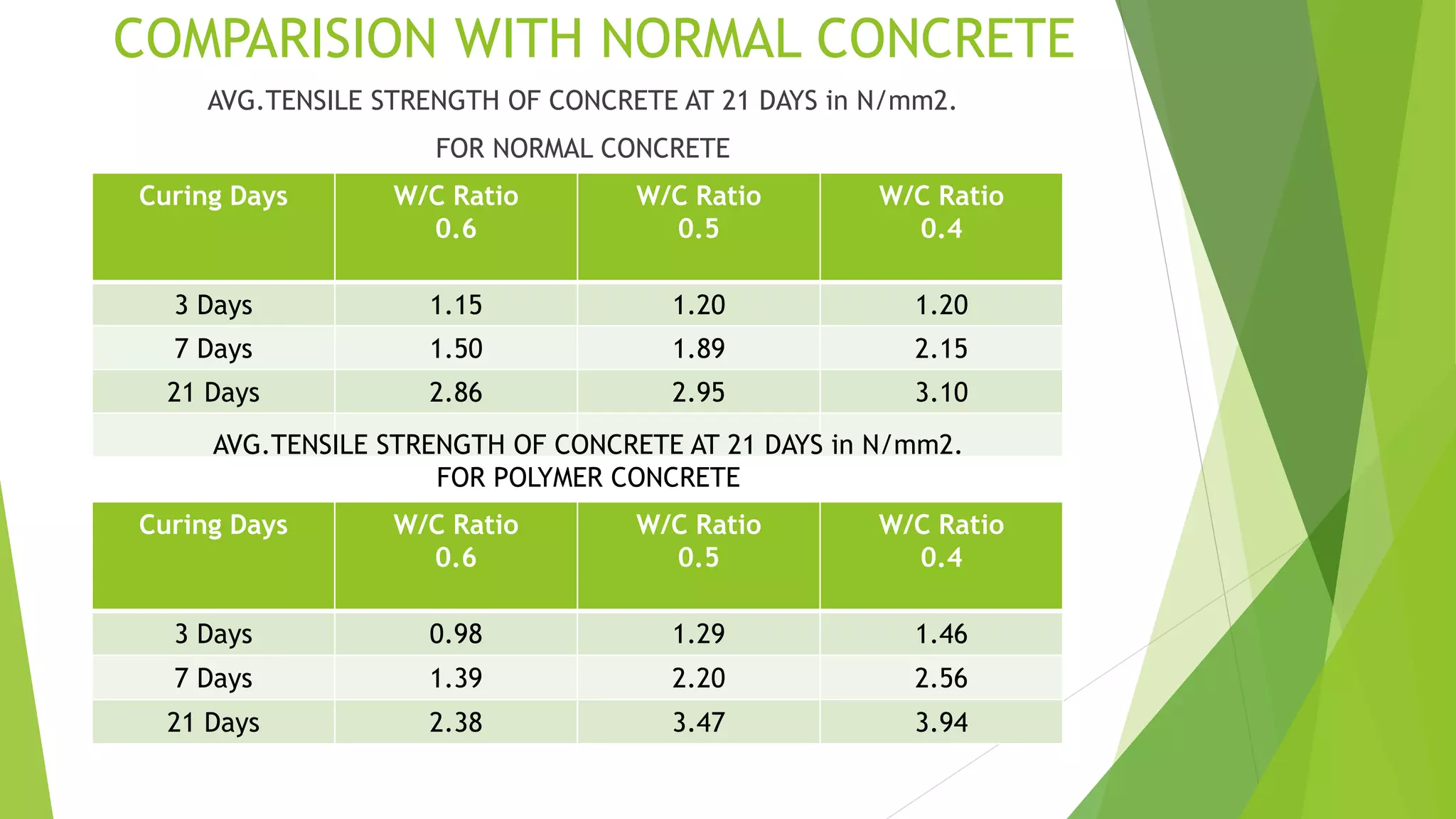

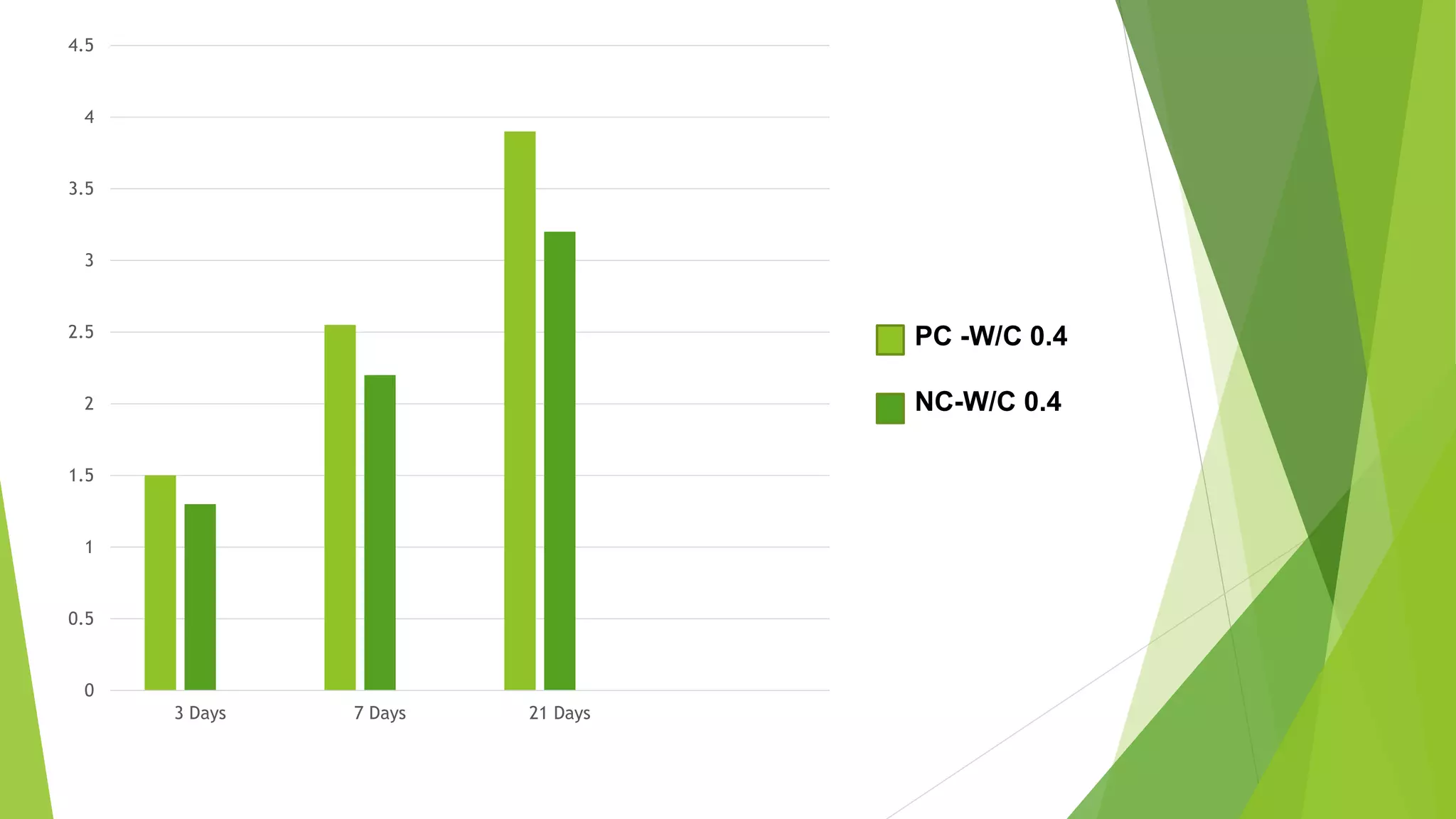

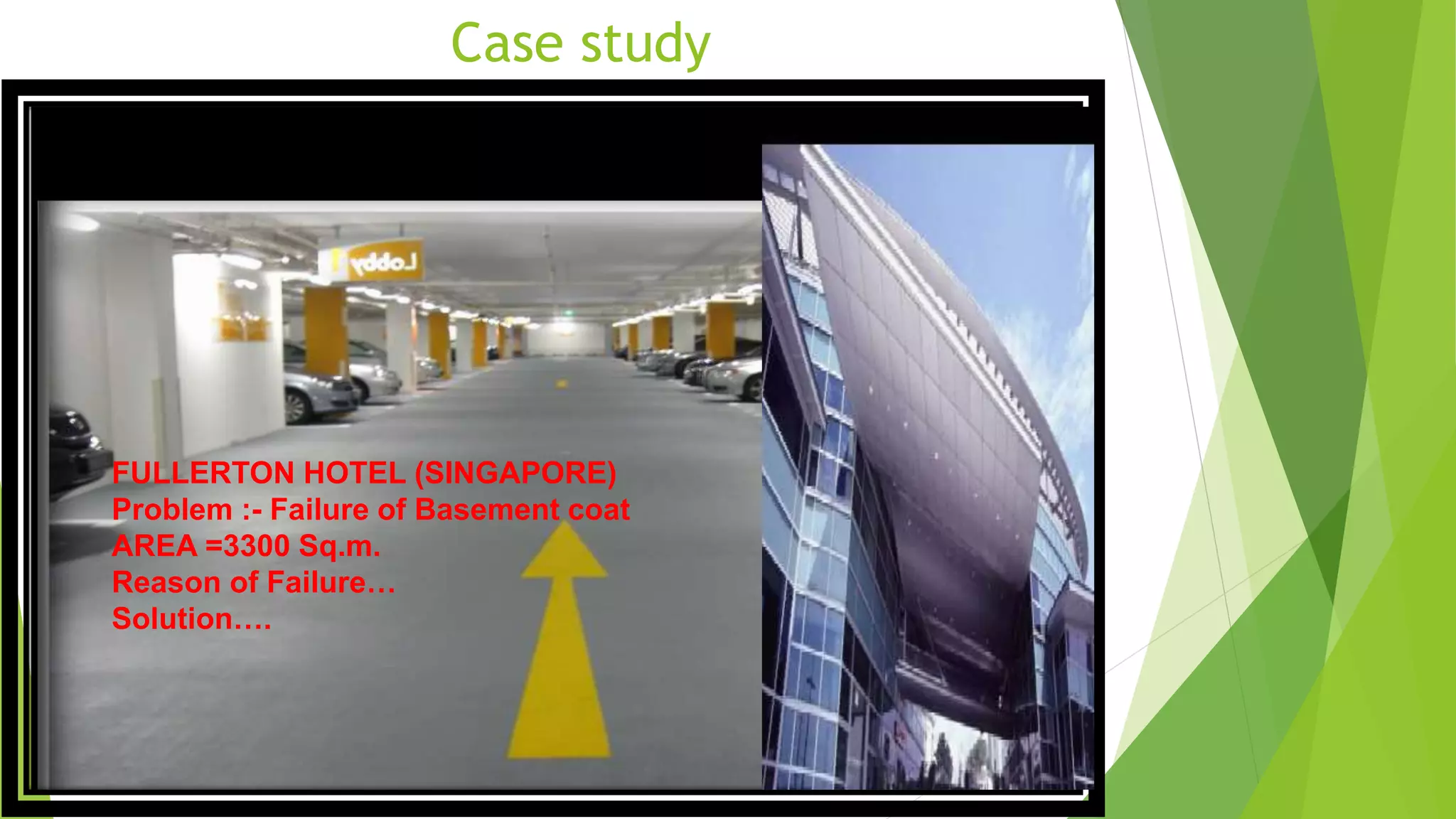

This document compares polymer concrete to normal concrete. Polymer concrete contains aggregates bonded together with polyester resins, making it lightweight and highly resistant to water absorption, freezing/thawing cycles, chemicals, and abrasion. It has higher compressive and tensile strengths than normal concrete, with compressive strength increasing up to 37% and tensile strength up to 21%. A case study examines how polymer concrete was used to repair basement coat failures at a hotel in Singapore. The document concludes polymer concrete has improved workability and strength properties over normal concrete.