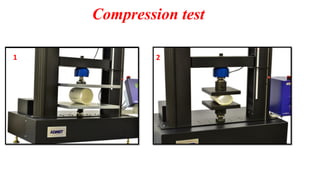

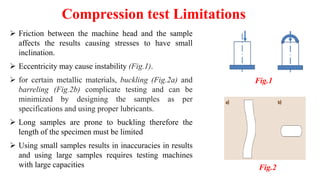

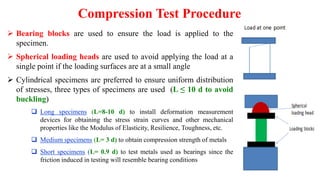

This document summarizes a lecture on compression testing. It discusses how compression tests are used to determine material properties like compressive strength and modulus of elasticity. The test involves placing a sample in a universal testing machine and applying a compressive load until failure. Common applications include the aerospace, automotive, and construction industries. While easier than tension tests, compression tests can be impacted by friction, eccentric loading, and buckling of the sample. The document outlines best practices for sample geometry and preparation to minimize these issues and get accurate results.