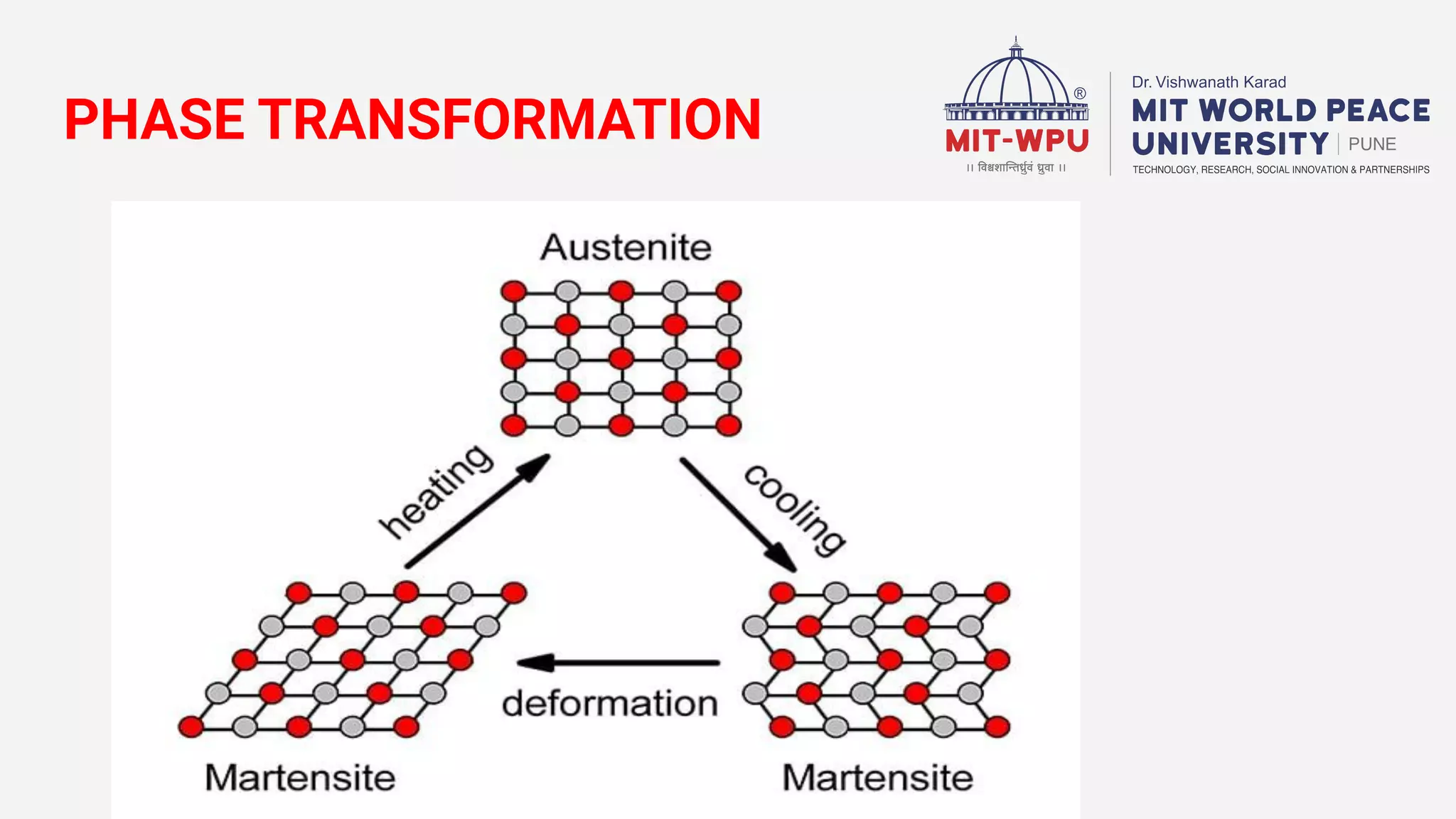

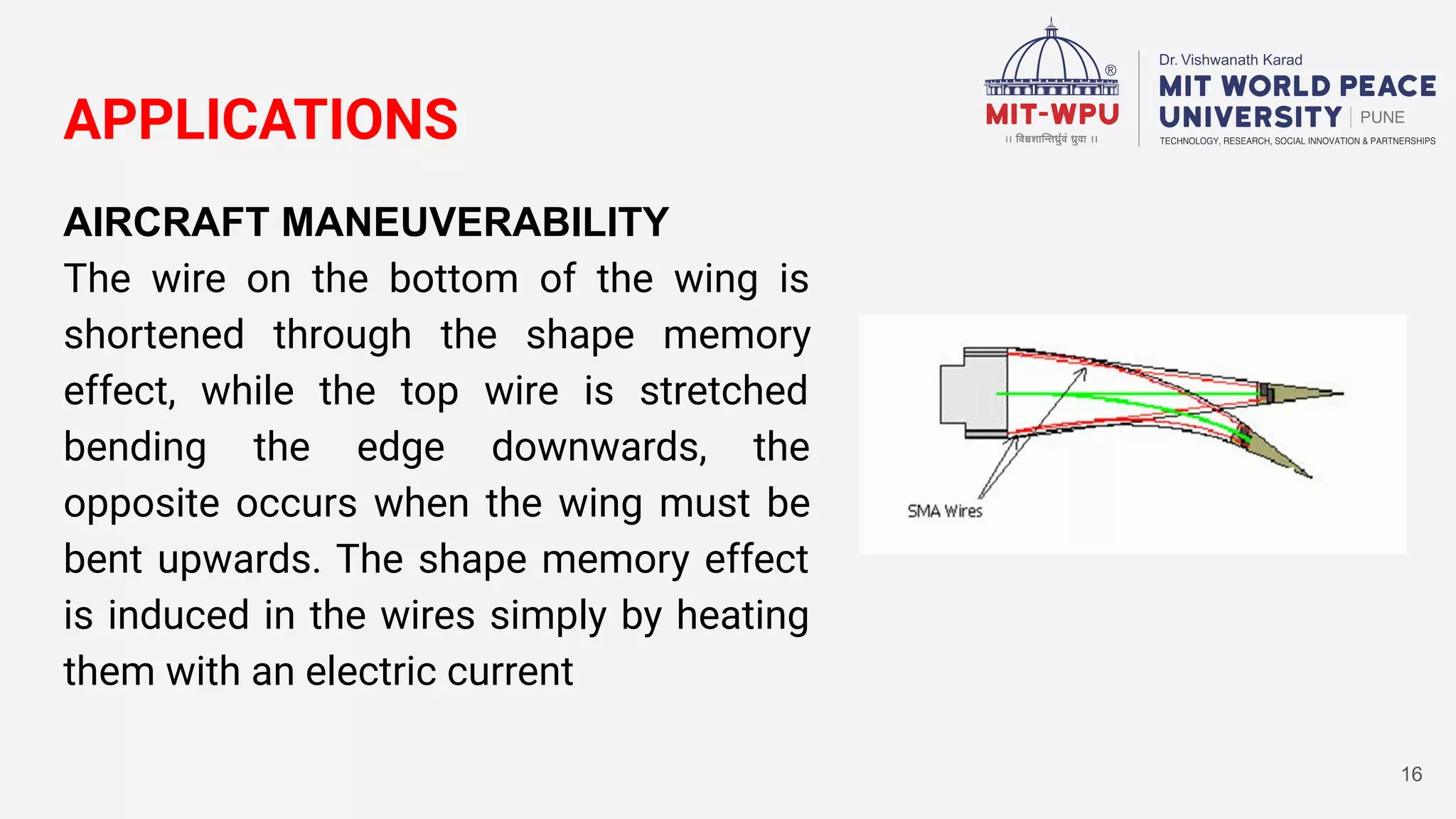

Shape memory alloys exhibit the shape memory effect, where alloys that are deformed at one temperature will recover their original shape when heated above a transformation temperature. Common shape memory alloys include nickel titanium (NiTiNOL) and copper-zinc-aluminum. Shape memory alloys have two crystal structures - austenite, which is stable at high temperatures, and martensite, which forms at lower temperatures. The shape memory effect occurs due to a reversible phase transformation between the martensite and austenite structures. Applications of shape memory alloys include aircraft control surfaces, medical devices, damping systems, robots, and thermal/electrical actuators.

![BIOCOMPATIBLE AND BIOMEDICAL APPLICATIONS: -

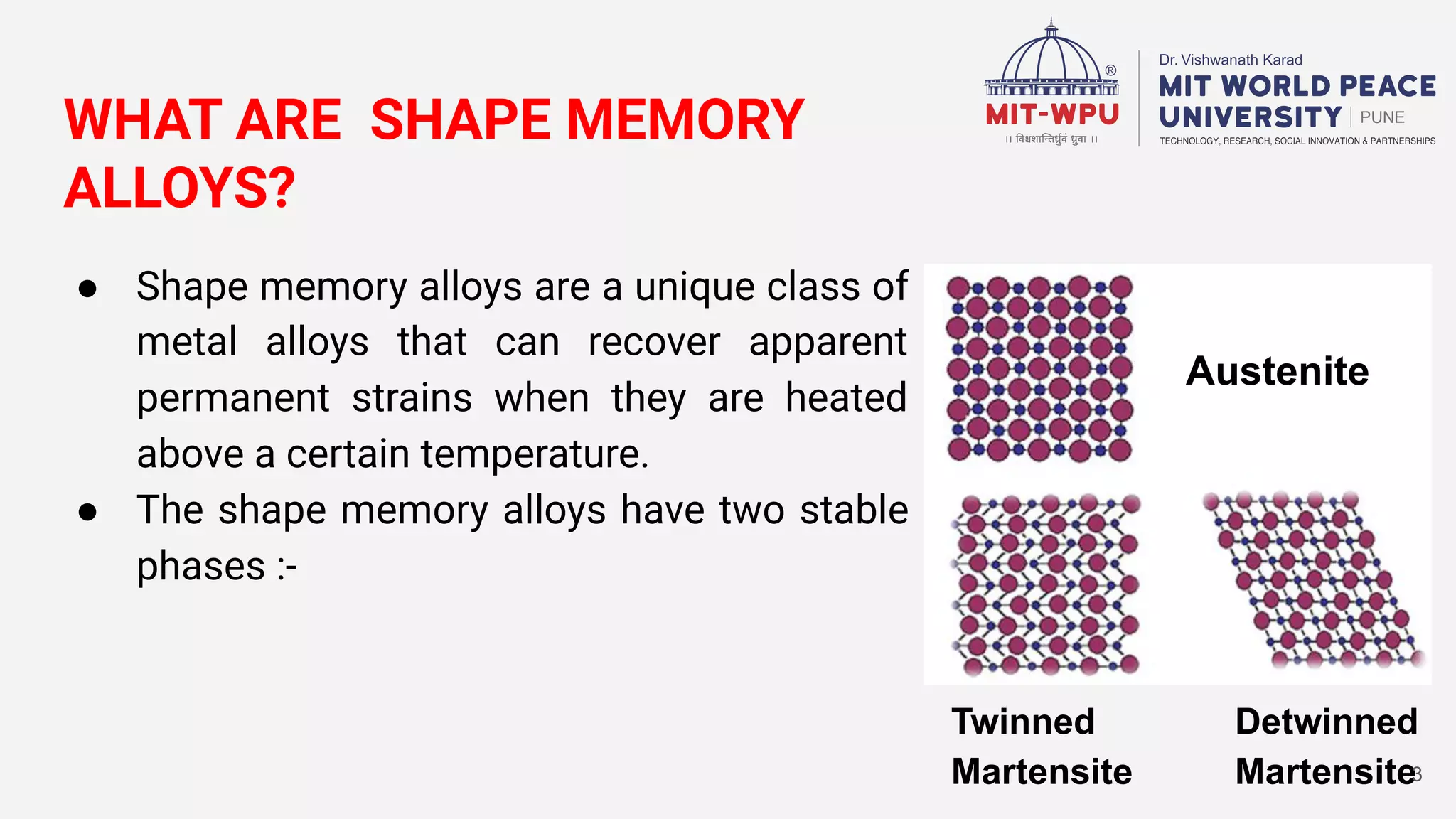

● Nitinol is highly biocompatible and has properties suitable for use in

orthopedic implants. Due to Nitinol’s unique properties it has seen a large

demand for use in less invasive medical devices. Nitinol tubing is commonly

used in catheters, stents, and super elastic needles.

● In colorectal surgery [1], the material is used in devices for reconnecting the

intestine after removing the pathology.

● Nitinol is used for devices developed by Franz Freudenthal to treat Patent

ductus arteriosus, blocking a blood vessel that bypasses the lungs and has

failed to close after birth in an infant.

● A more recent application of nitinol wire is in female contraception,

specifically in intrauterine devices.](https://image.slidesharecdn.com/shapememoryalloy-210606150400/75/Shape-memory-alloy-19-2048.jpg)