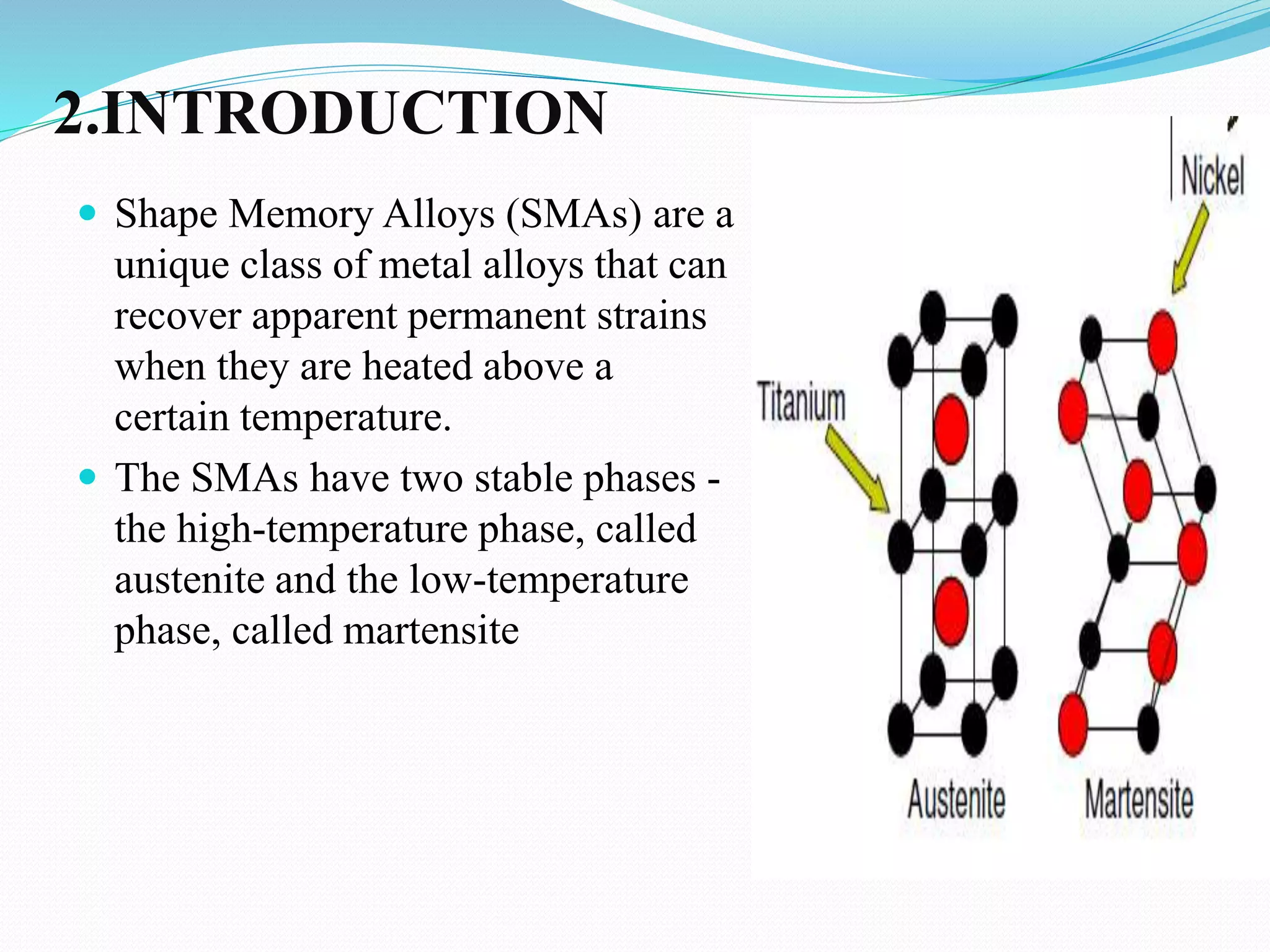

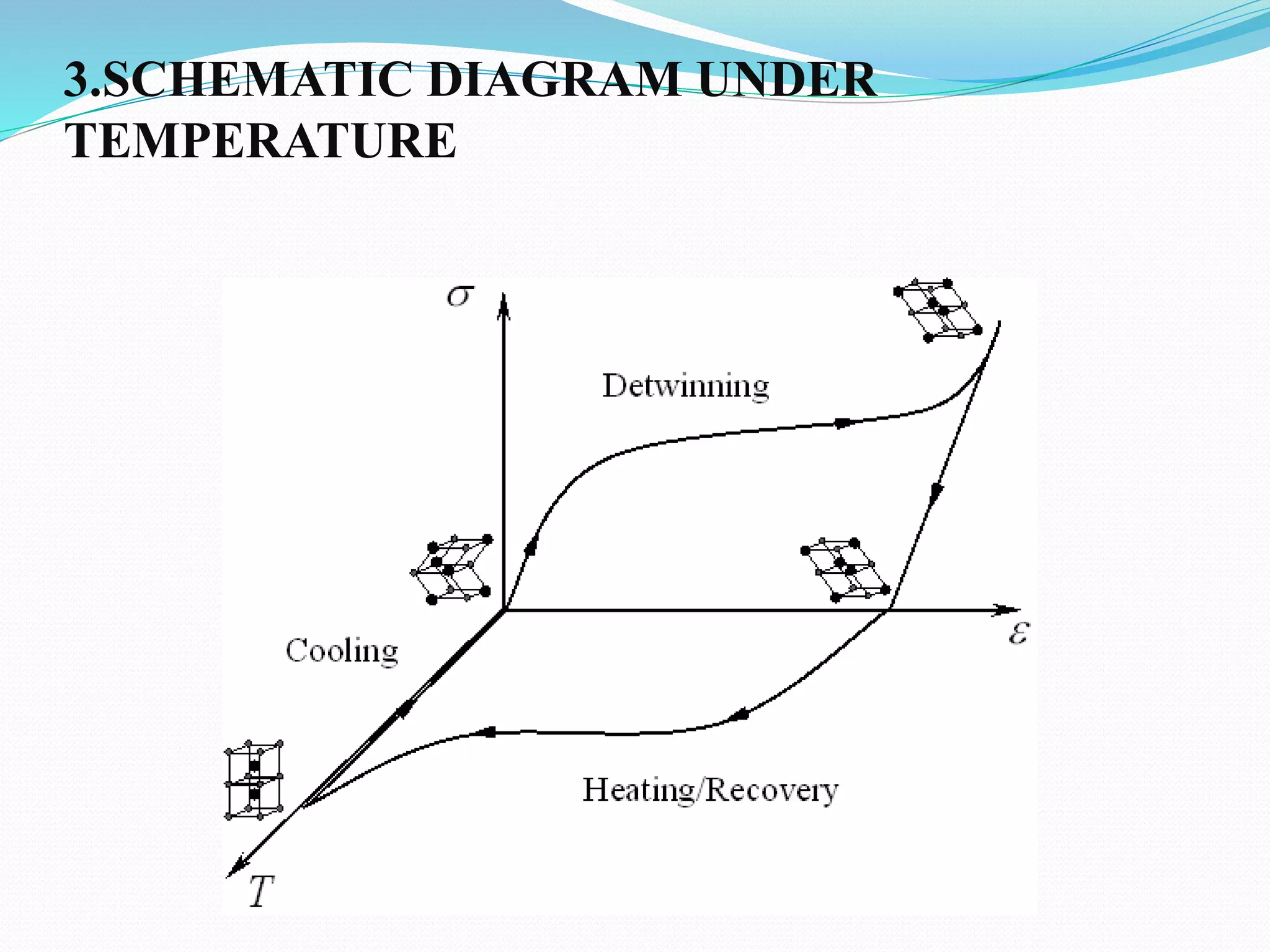

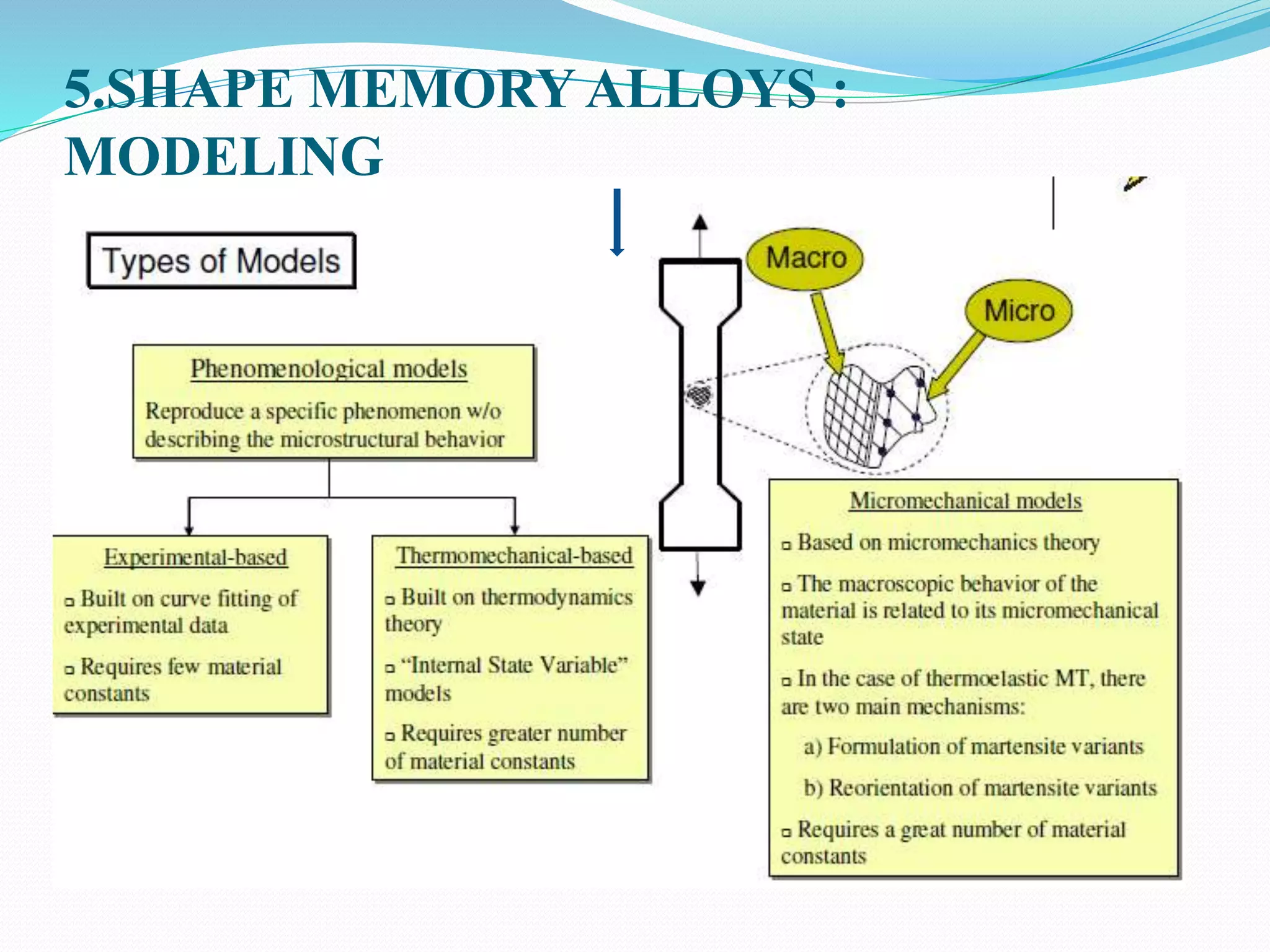

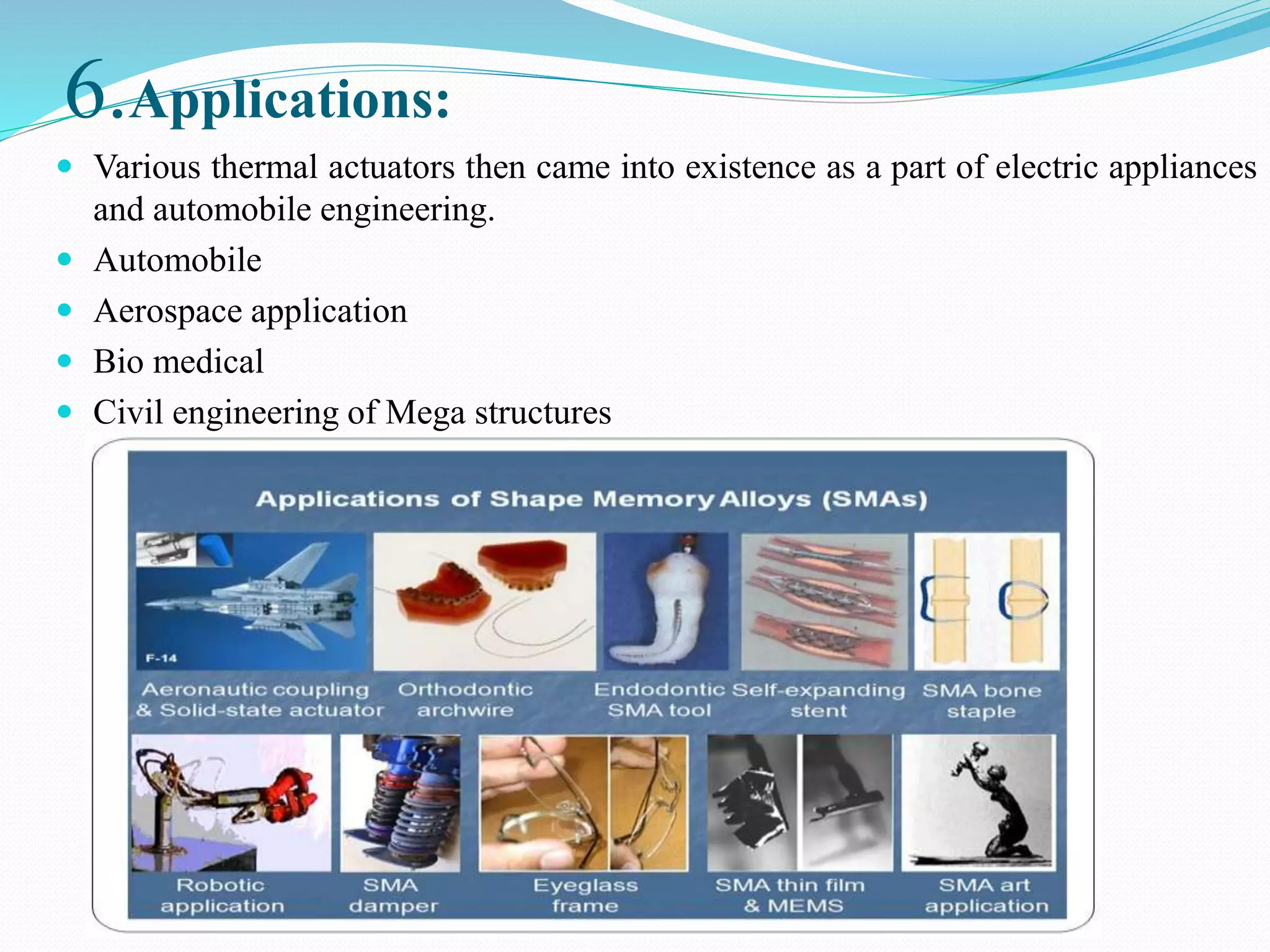

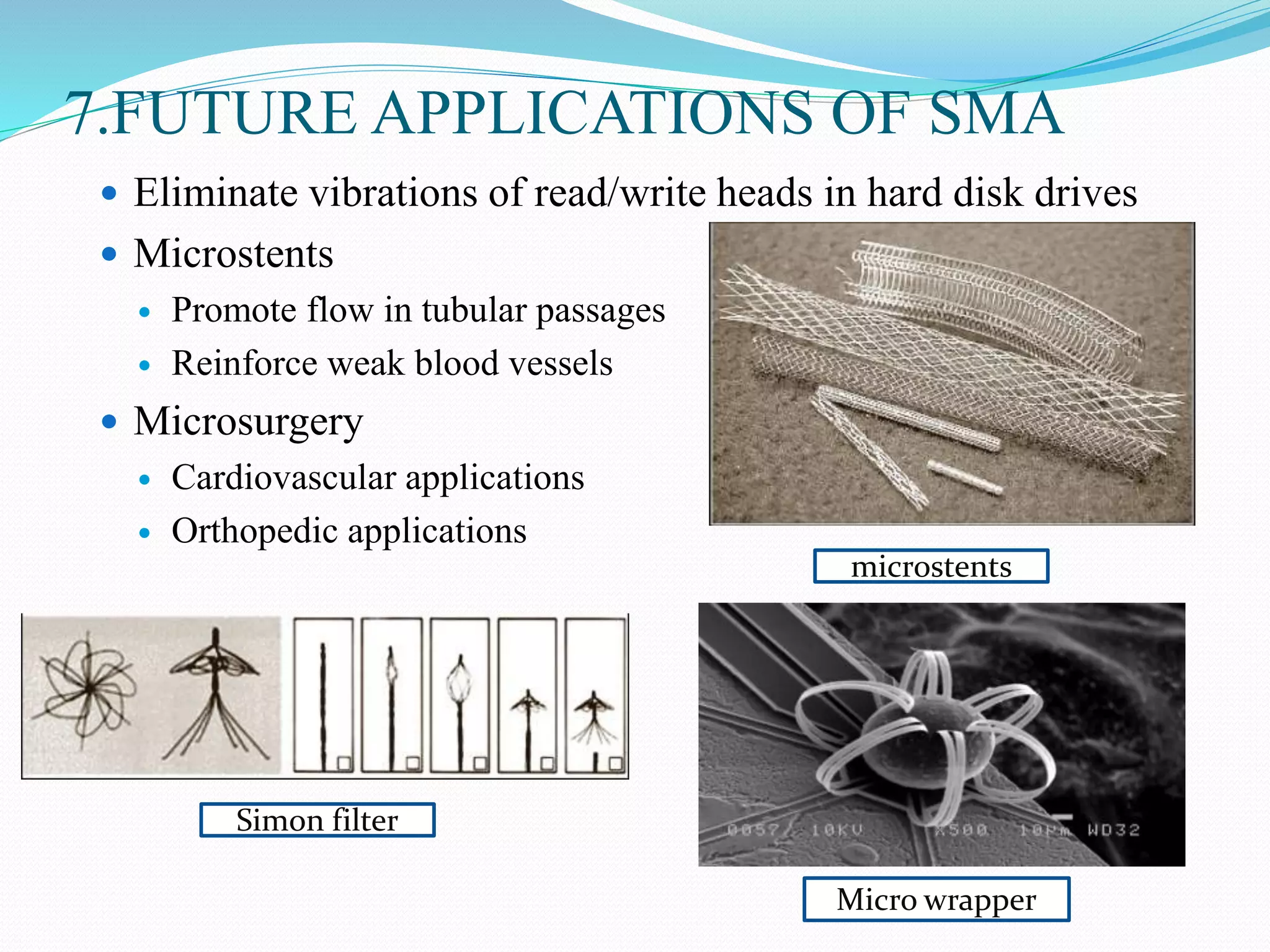

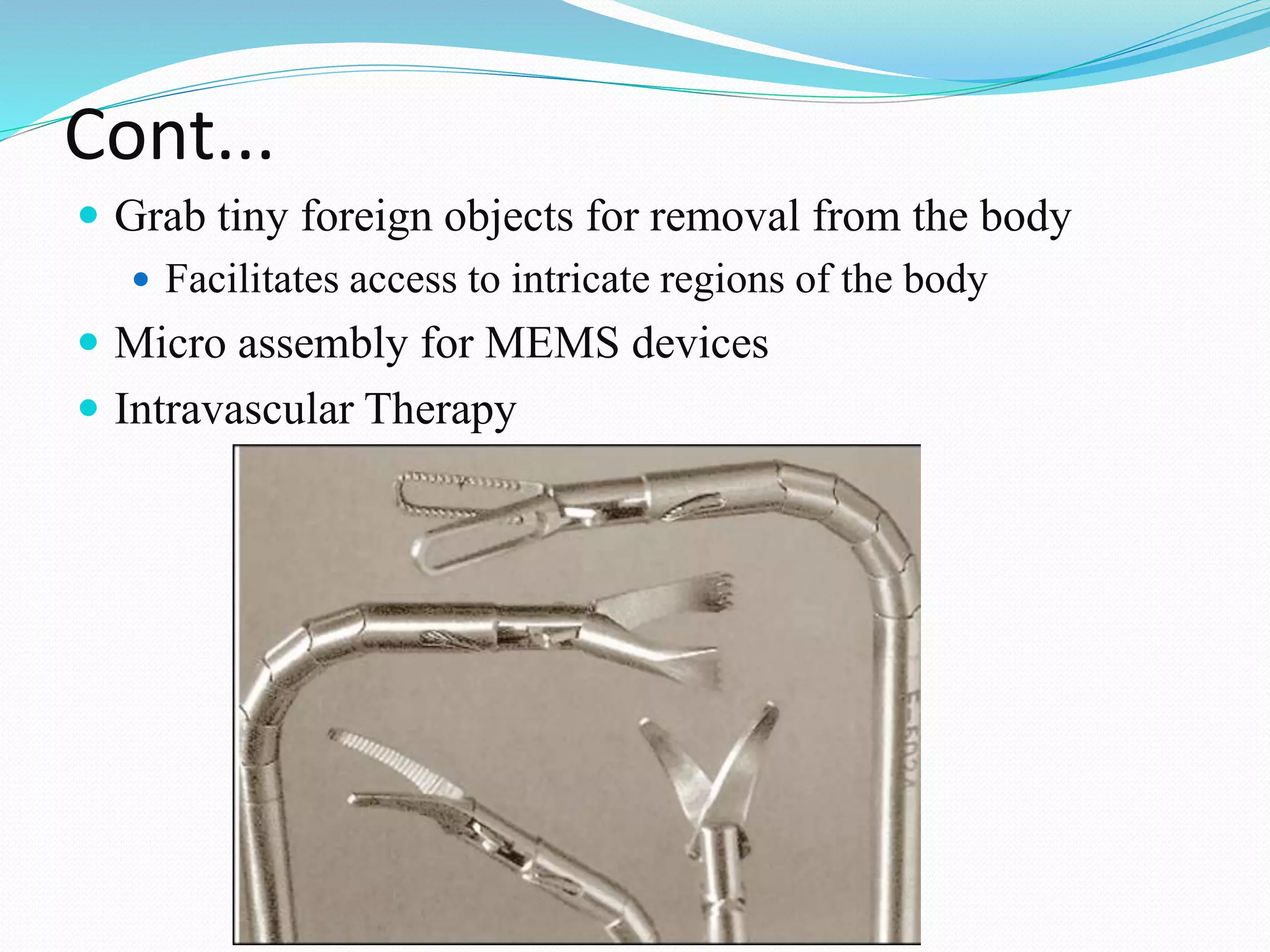

Shape Memory Alloys (SMAs) are metals that can recover permanent deformations upon heating, consisting mainly of austenite and martensite phases. They have diverse applications in fields such as automotive, aerospace, and biomedical engineering, along with notable advantages like high strength and elasticity, but face challenges such as high costs and sensitivity in fabrication. The document outlines the history, properties, applications, and future prospects of SMAs, emphasizing their potential in advanced technologies.