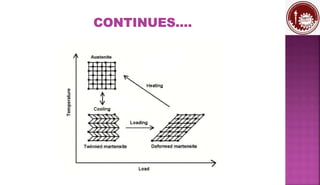

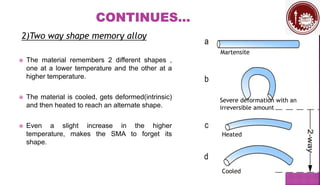

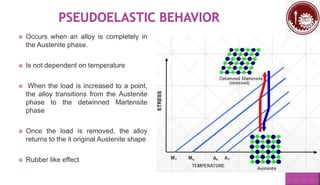

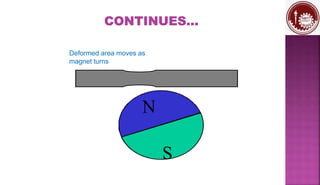

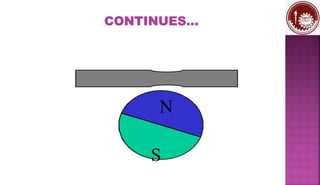

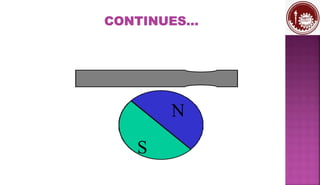

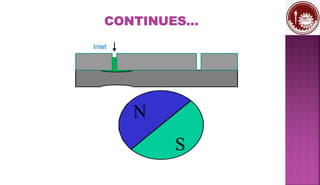

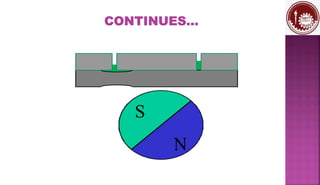

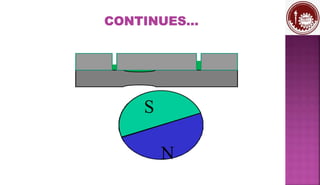

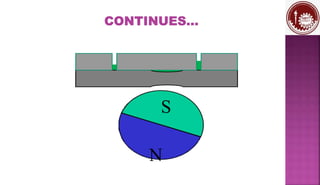

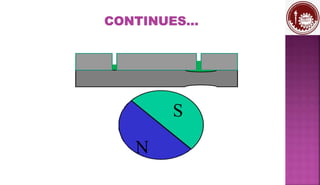

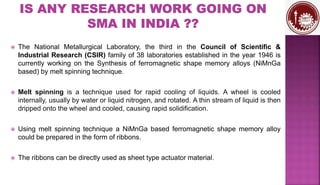

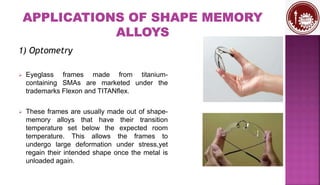

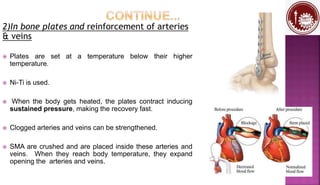

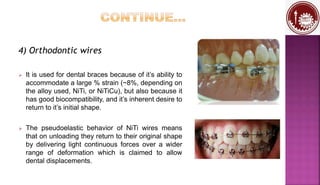

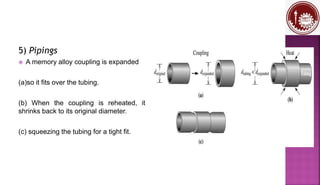

Shape memory alloys are smart materials that can remember their original shape and return to it when heated after being deformed. The most common shape memory alloys are nickel-titanium, copper-zinc-aluminum, and copper-aluminum-nickel alloys. Shape memory alloys exhibit the shape memory effect and pseudoelasticity/superelasticity, allowing deformation without permanent deformation. They have applications in orthodontics, aircraft components, civil structures, robotics and more due to their unique properties. Research continues to enhance shape memory alloy properties and develop new alloys.