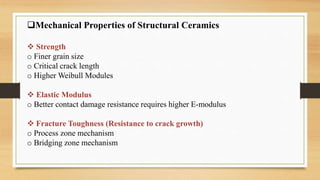

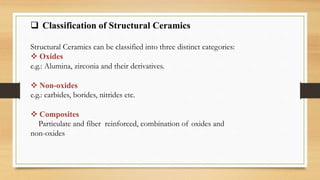

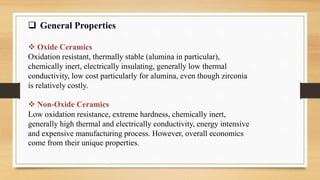

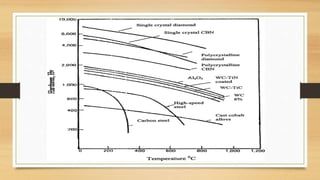

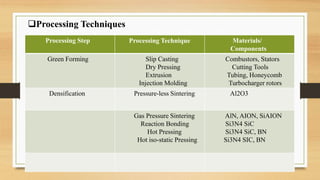

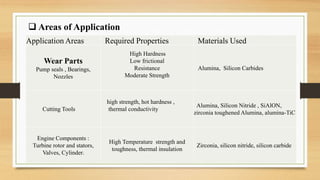

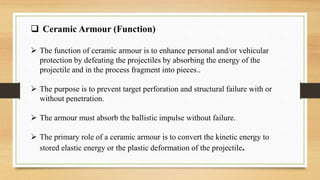

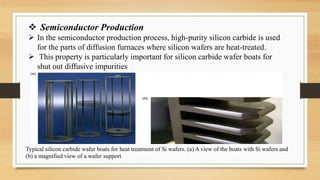

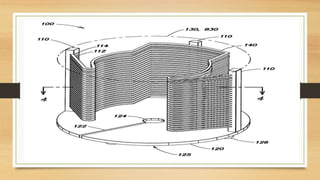

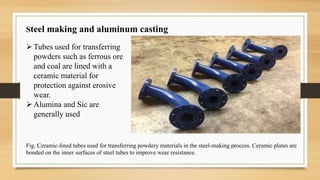

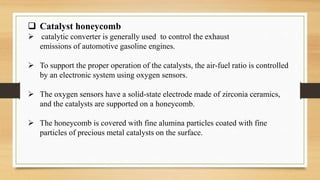

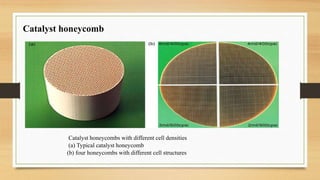

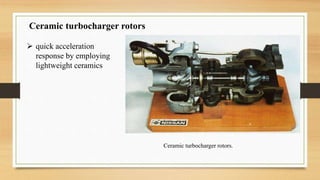

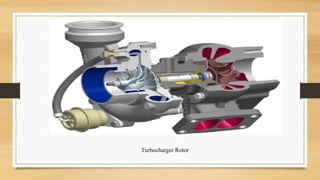

This document discusses structural ceramics, including their mechanical properties, classifications, general properties, processing techniques, and areas of application. It describes how structural ceramics are used in applications requiring properties like strength, hardness, heat resistance, and chemical inertness. Examples given include wear parts, cutting tools, engine components, armor, semiconductor production equipment, steel making, and catalytic converters. The document provides details on the materials used and processing methods for different applications of structural ceramics.