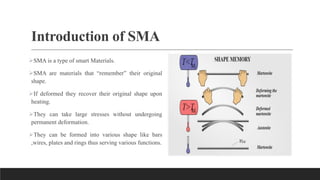

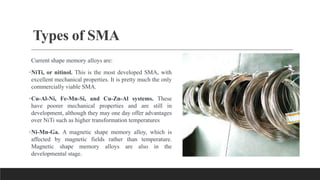

Shape memory alloys are smart materials that can "remember" their original shape. When deformed, they recover their shape upon heating due to a solid state phase transformation between their martensitic and austenitic crystalline forms. The most common type is nickel-titanium (Nitinol) alloy. Shape memory alloys find applications that use their shape memory effect and pseudoelasticity, such as in medical devices, actuators, and vibration dampeners. While shape memory alloys have advantages like high strength and power-to-weight ratio, their use is limited by poor fatigue properties and higher costs compared to other materials.