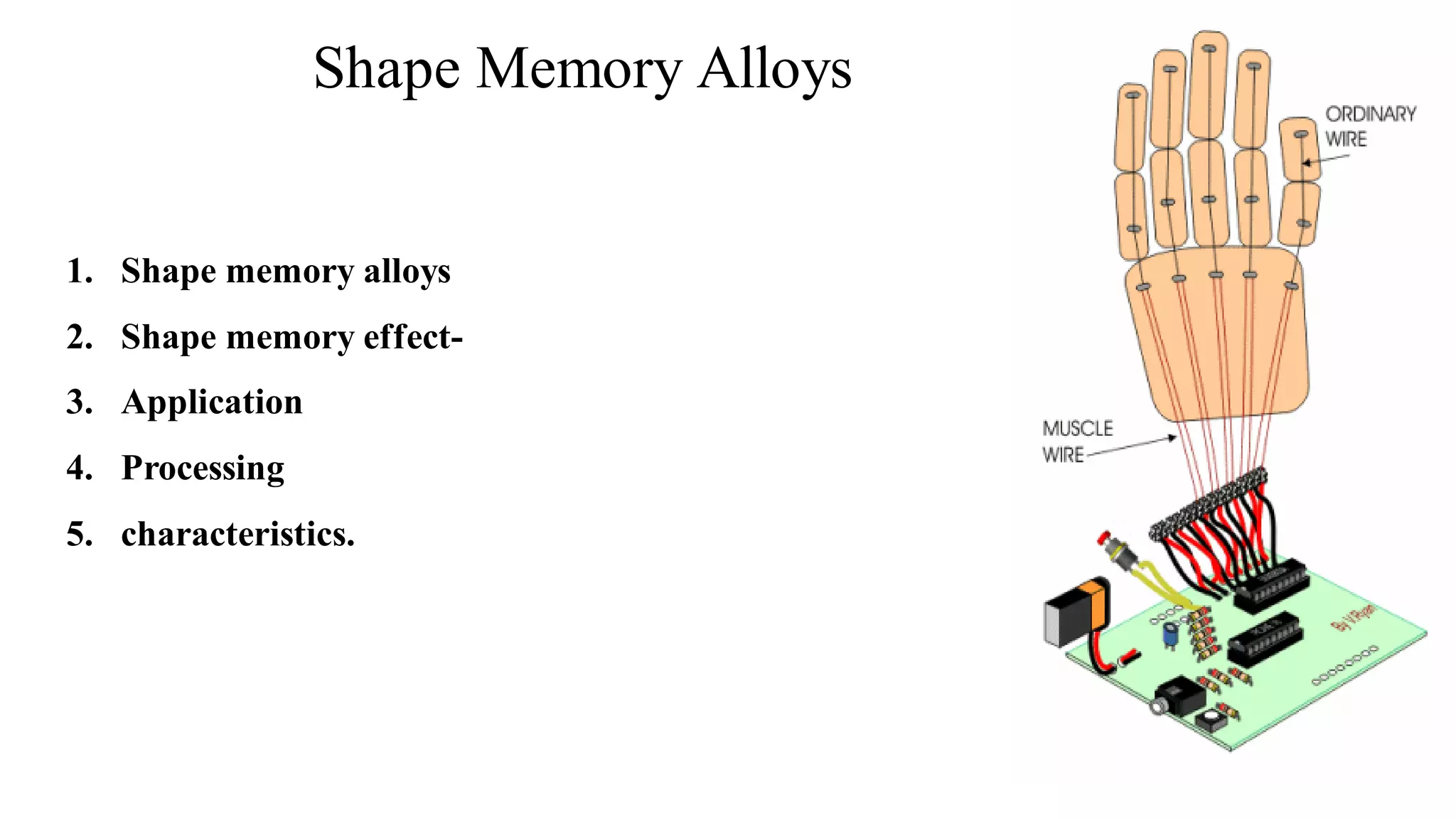

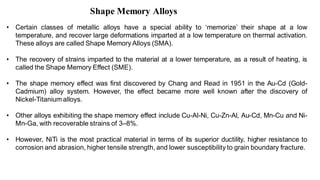

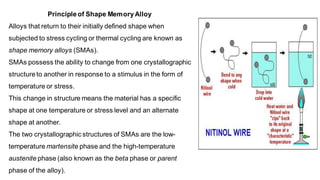

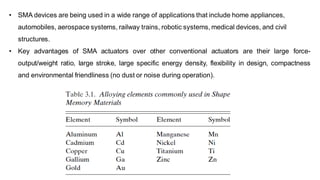

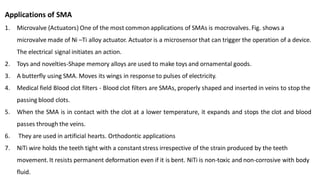

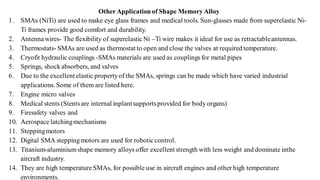

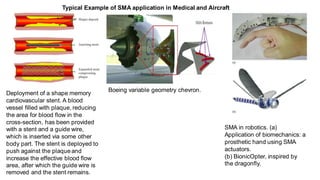

Shape memory alloys have the ability to remember their original shape after being deformed at a lower temperature. This is known as the shape memory effect. When heat is applied, the alloy returns to its pre-deformed shape. Nickel-titanium alloys were the first widely used shape memory alloys. Shape memory alloys have applications in areas like medical devices, home appliances, aerospace, and more due to their unique ability to change shape with temperature changes. They can provide large forces, strokes, and energy densities compared to traditional actuators.