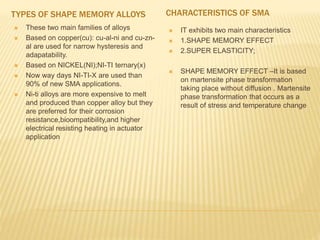

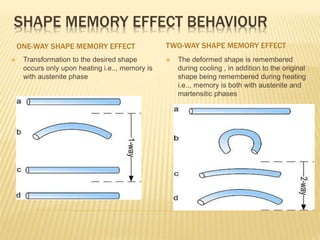

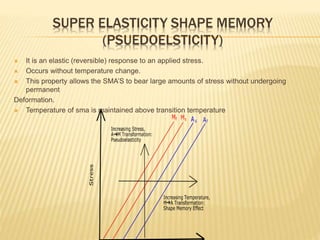

Shape Memory Alloys (SMA) are materials that can return to their original shape when heated after being deformed, showcasing properties like shape memory effect and superelasticity. The document discusses the history, characteristics, advantages, and various applications of SMA, including use in robotics and civil structures. Future applications are anticipated in automotive and aerospace industries, underscoring the potential for ongoing research and development in this field.