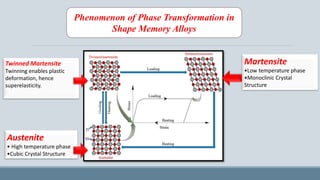

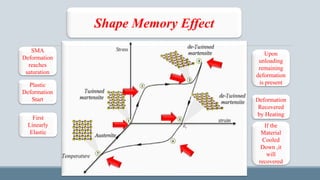

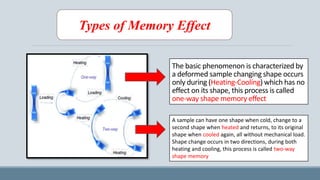

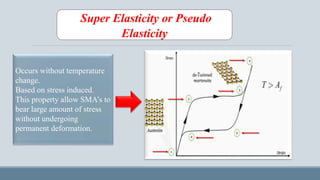

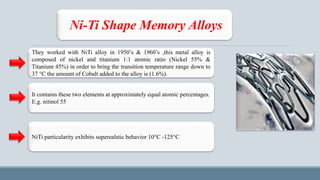

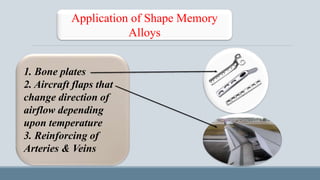

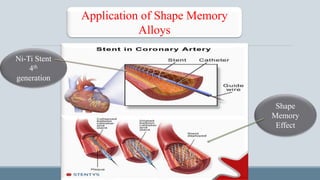

Ni-Ti shape memory alloys exhibit the shape memory effect and super elasticity. They consist of roughly equal parts nickel and titanium. Ni-Ti alloys can deform at low temperatures but return to their original shape when heated. This allows applications like self-expanding stents. Ni-Ti alloys are expensive but have advantages like high corrosion resistance and can be electrically controlled. Common applications include aircraft flaps, bone plates, and arterial reinforcement.