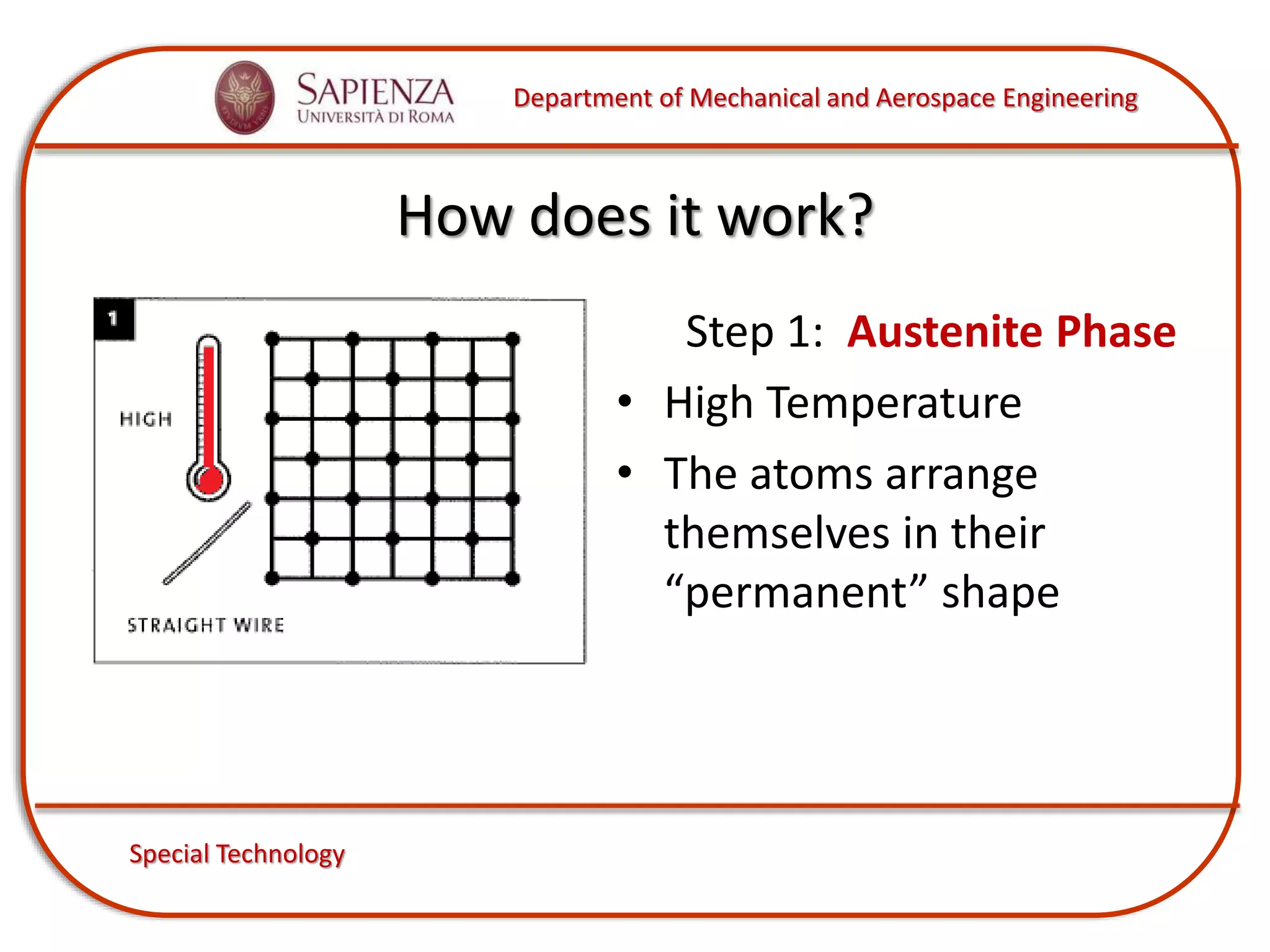

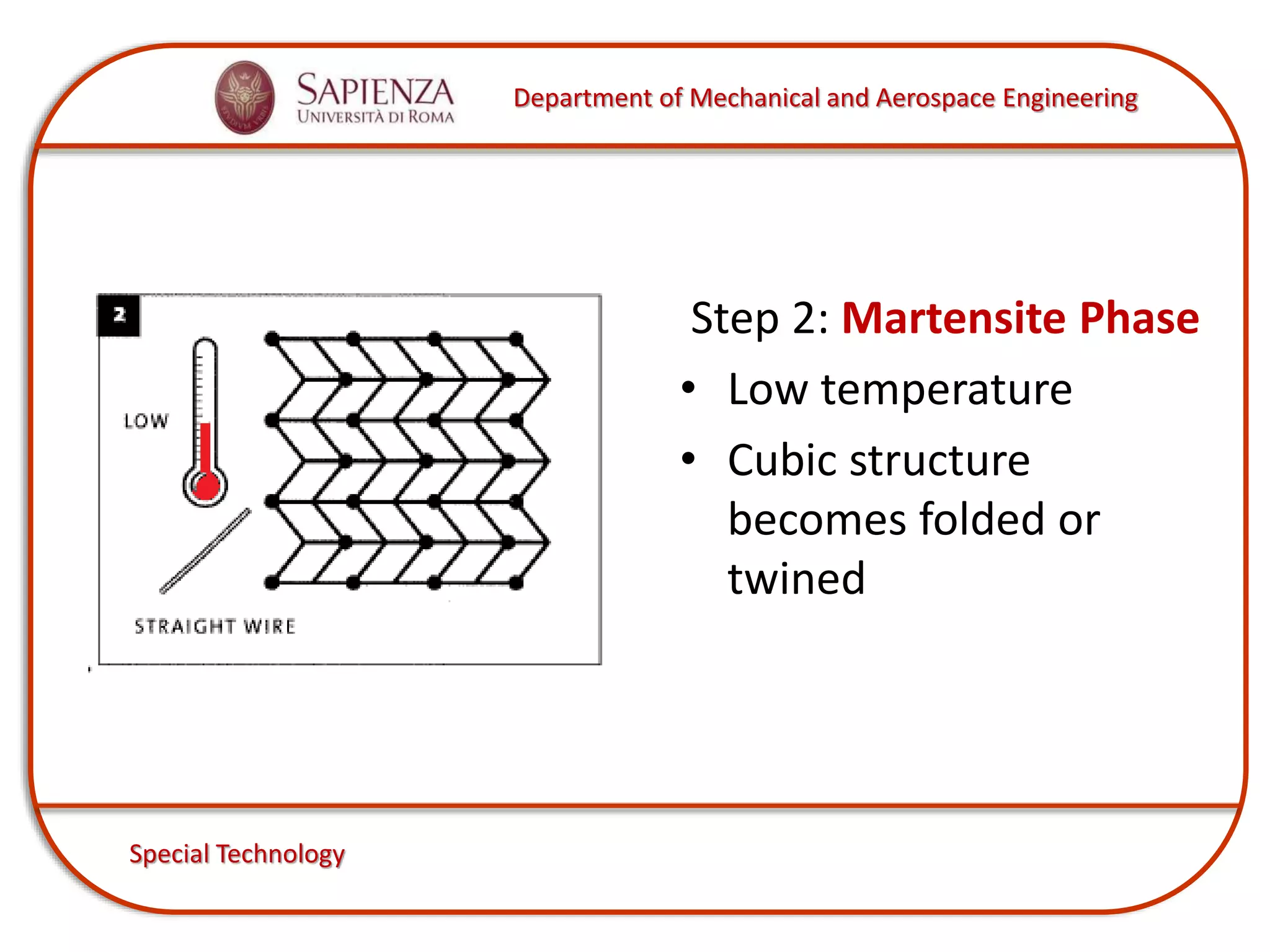

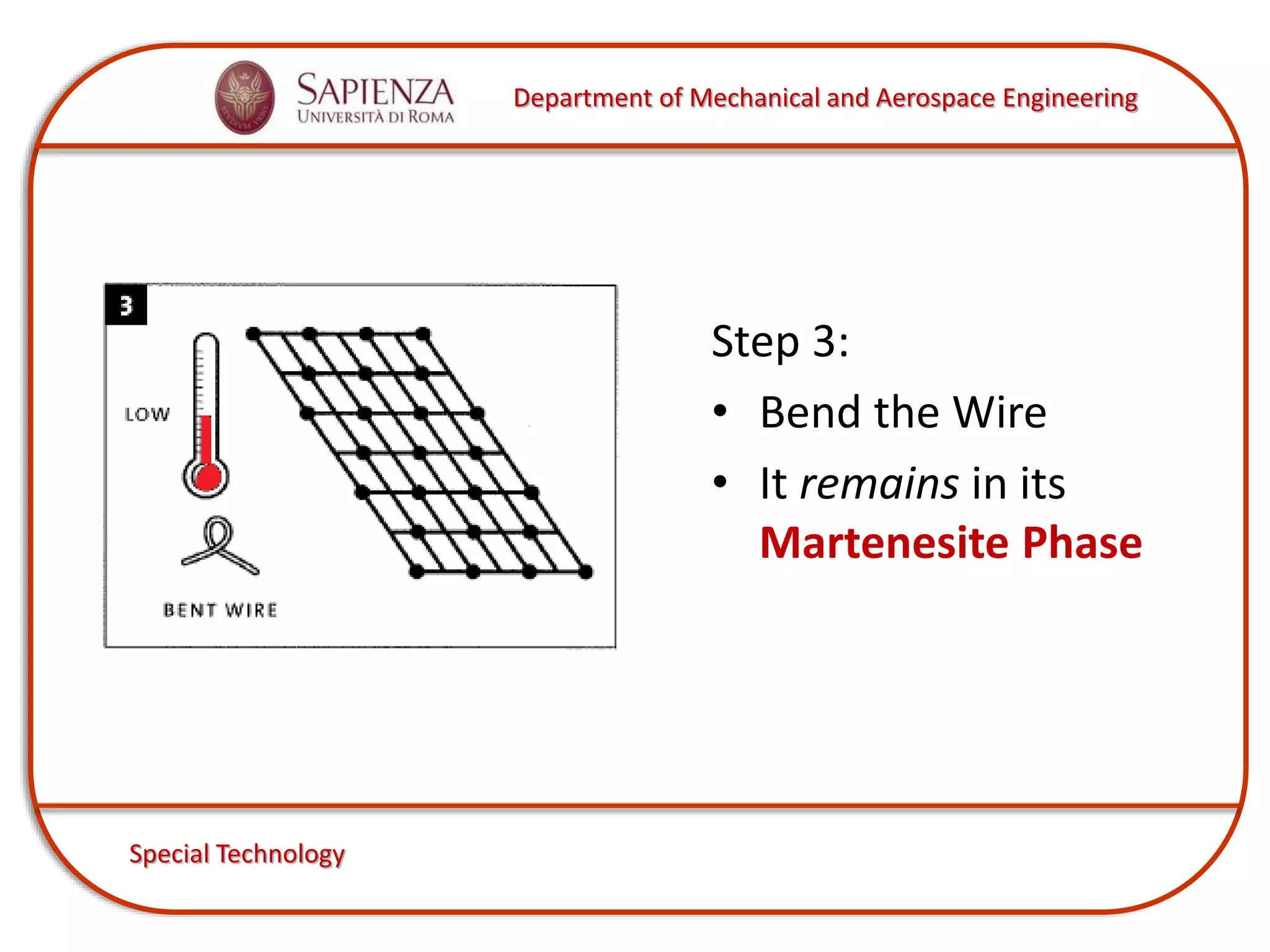

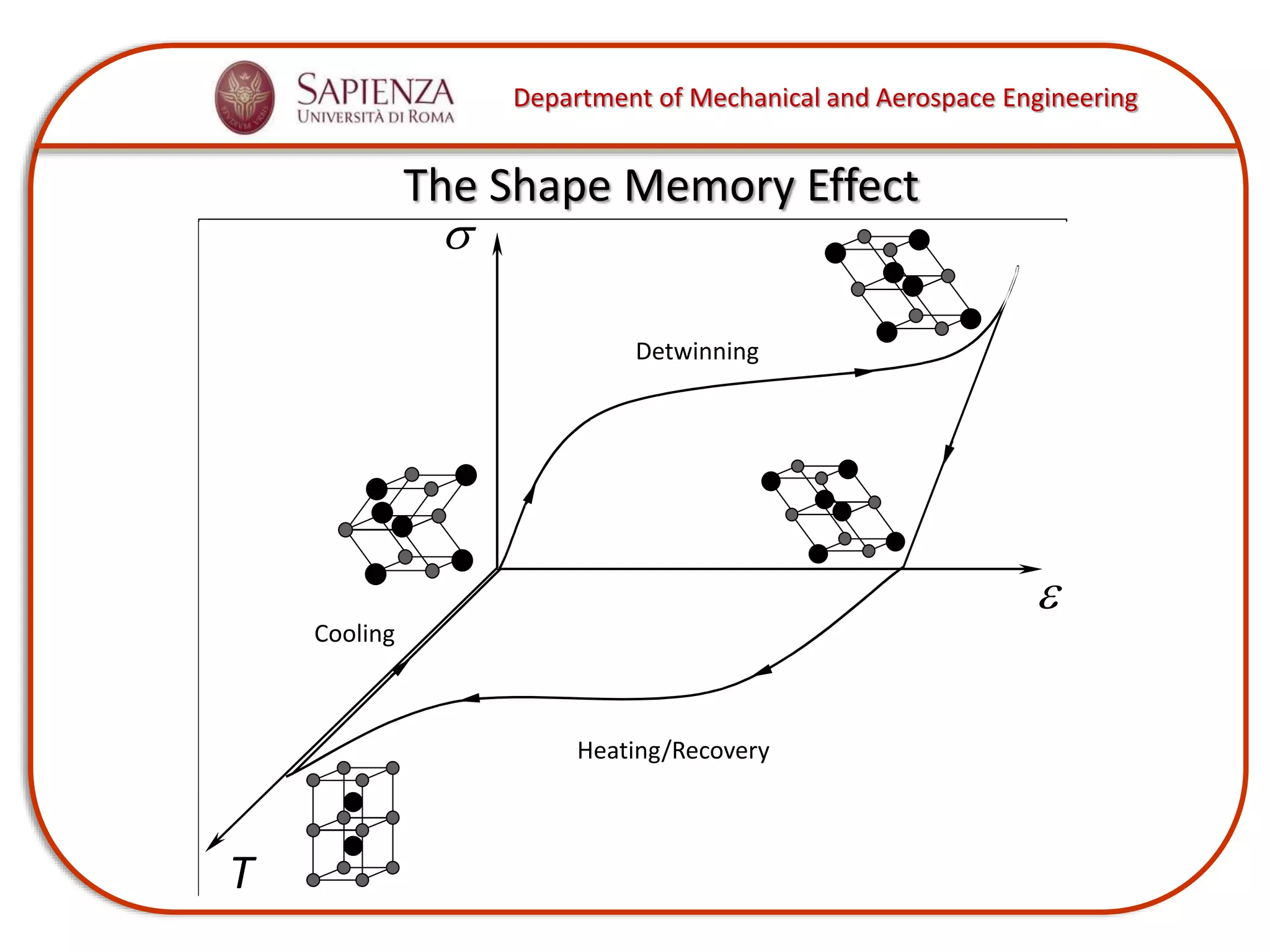

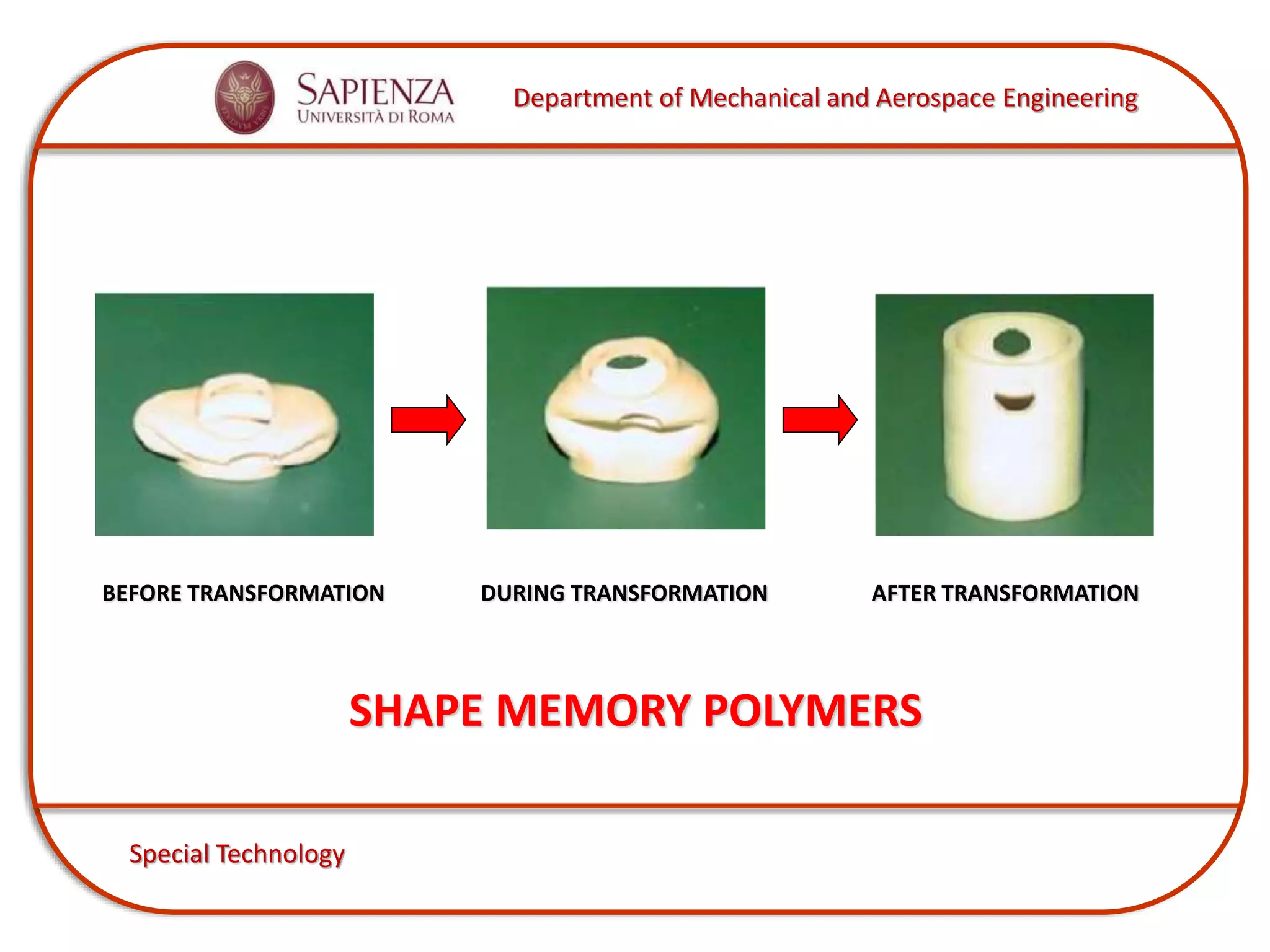

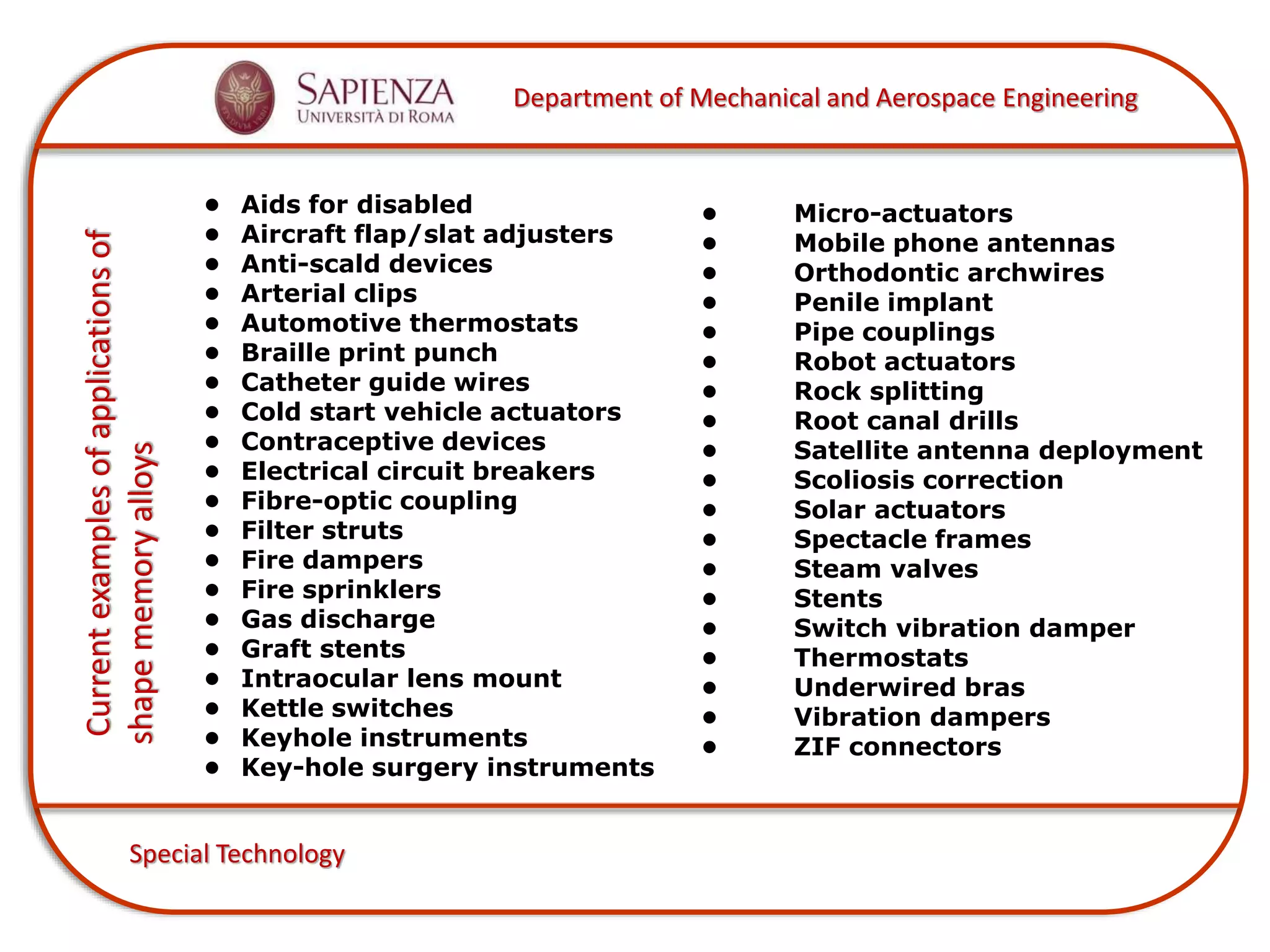

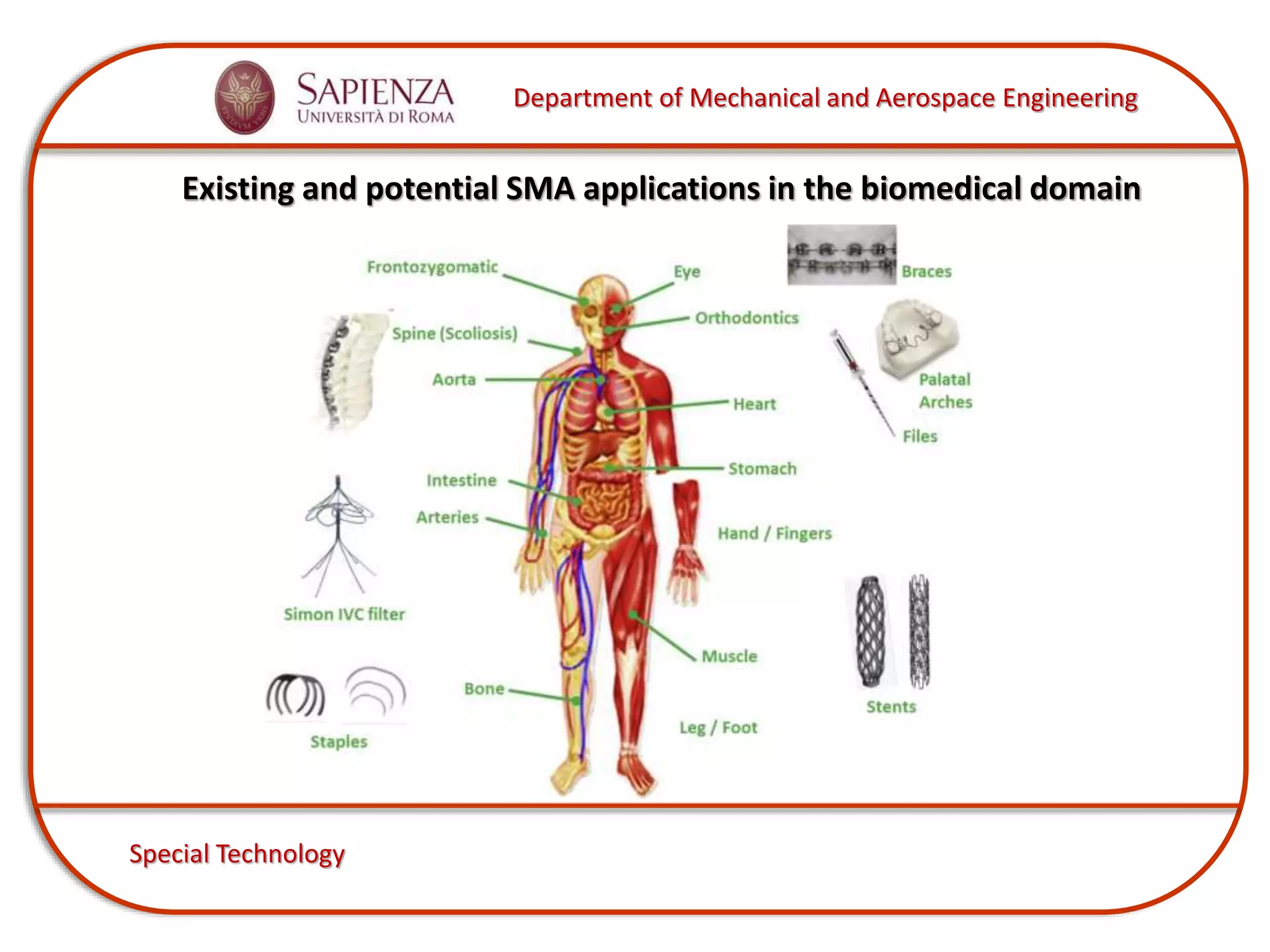

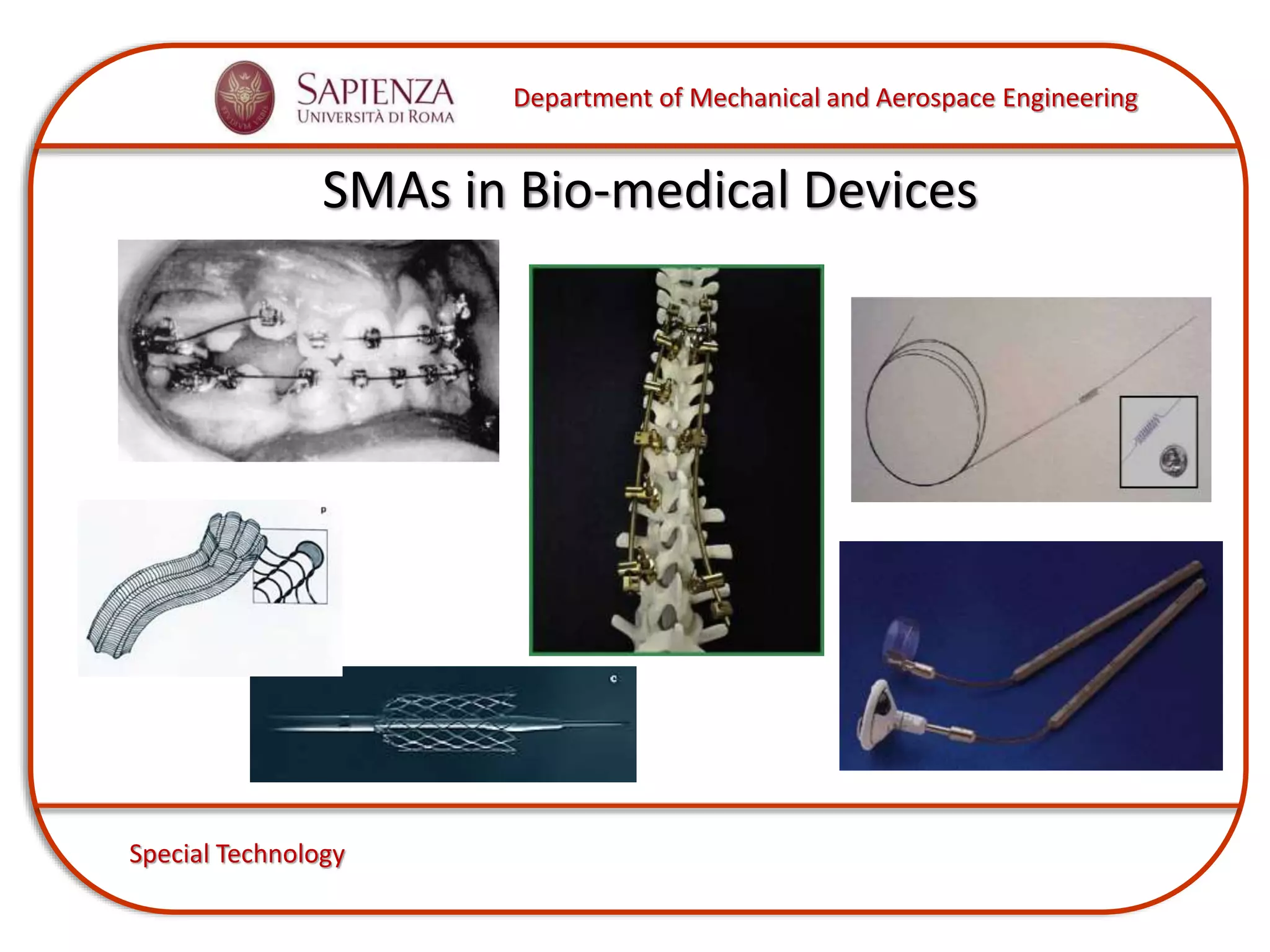

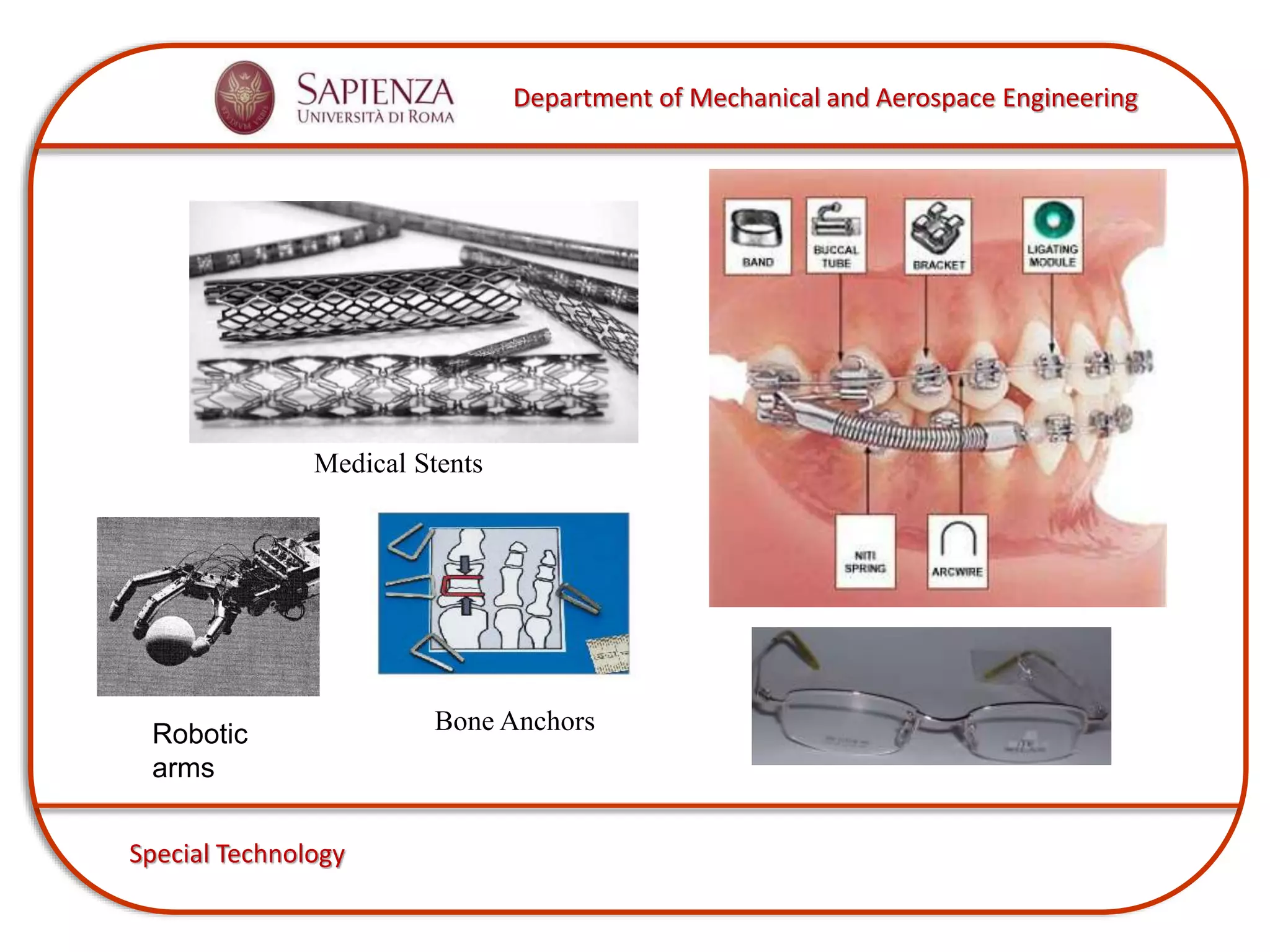

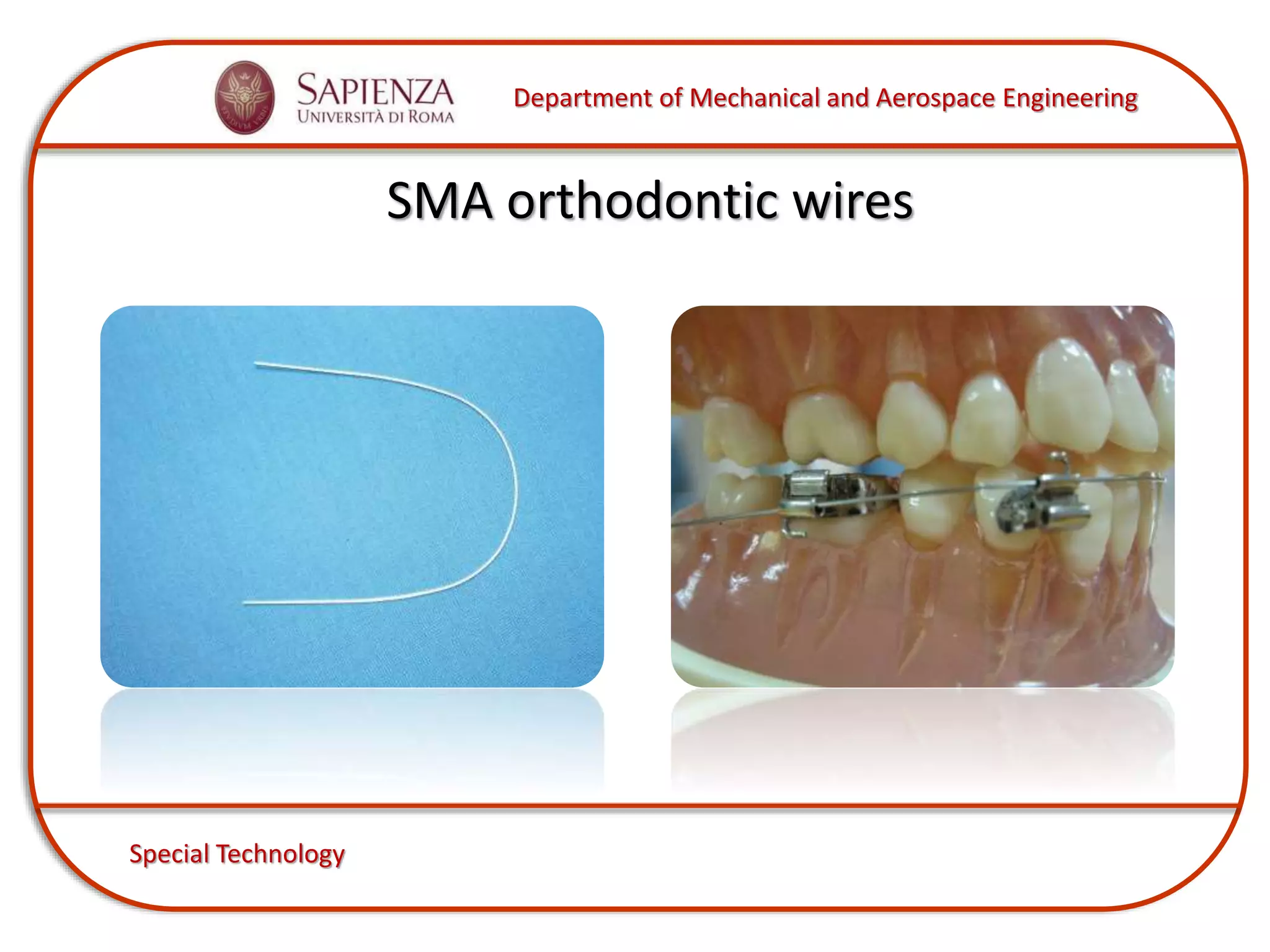

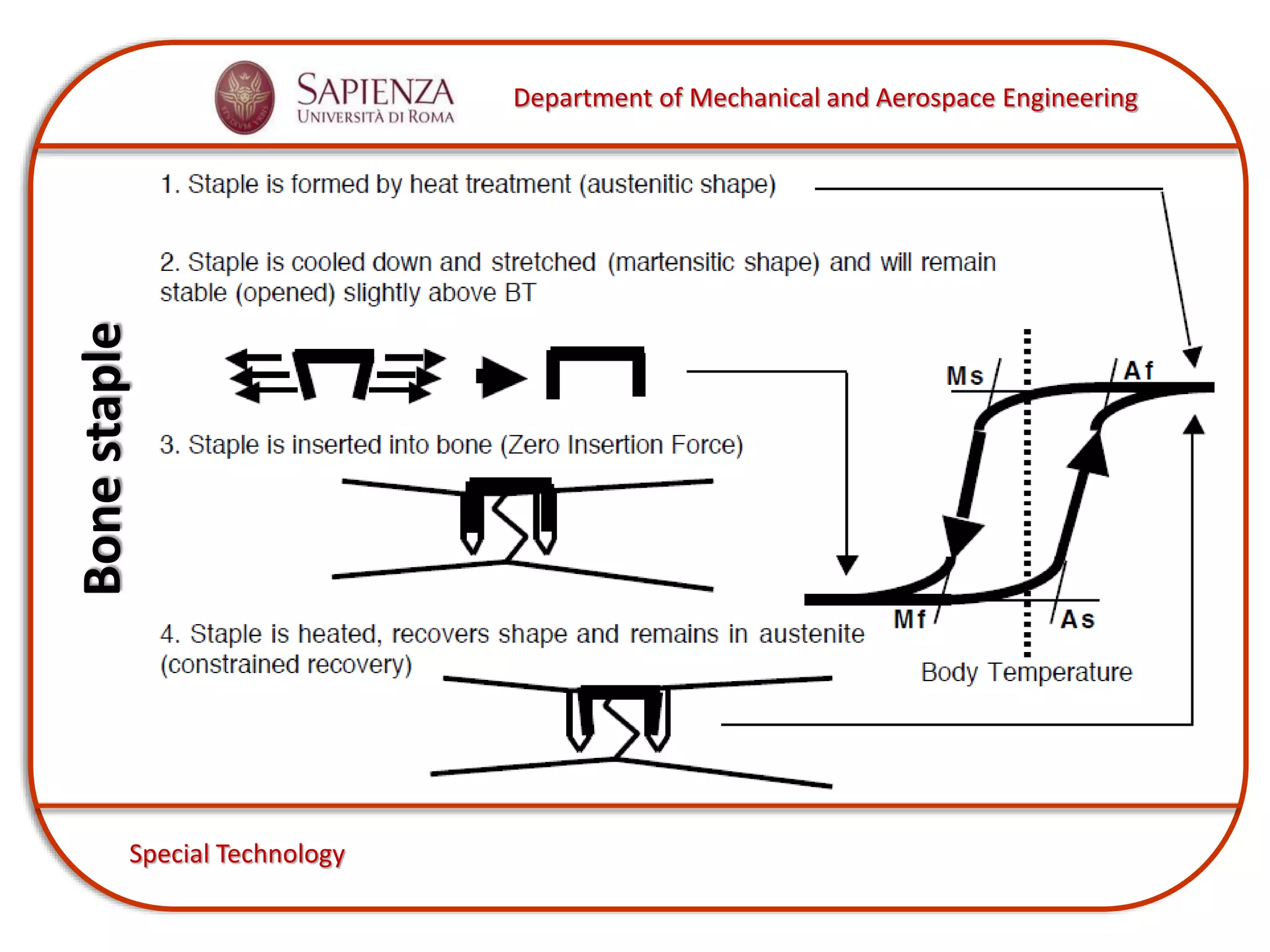

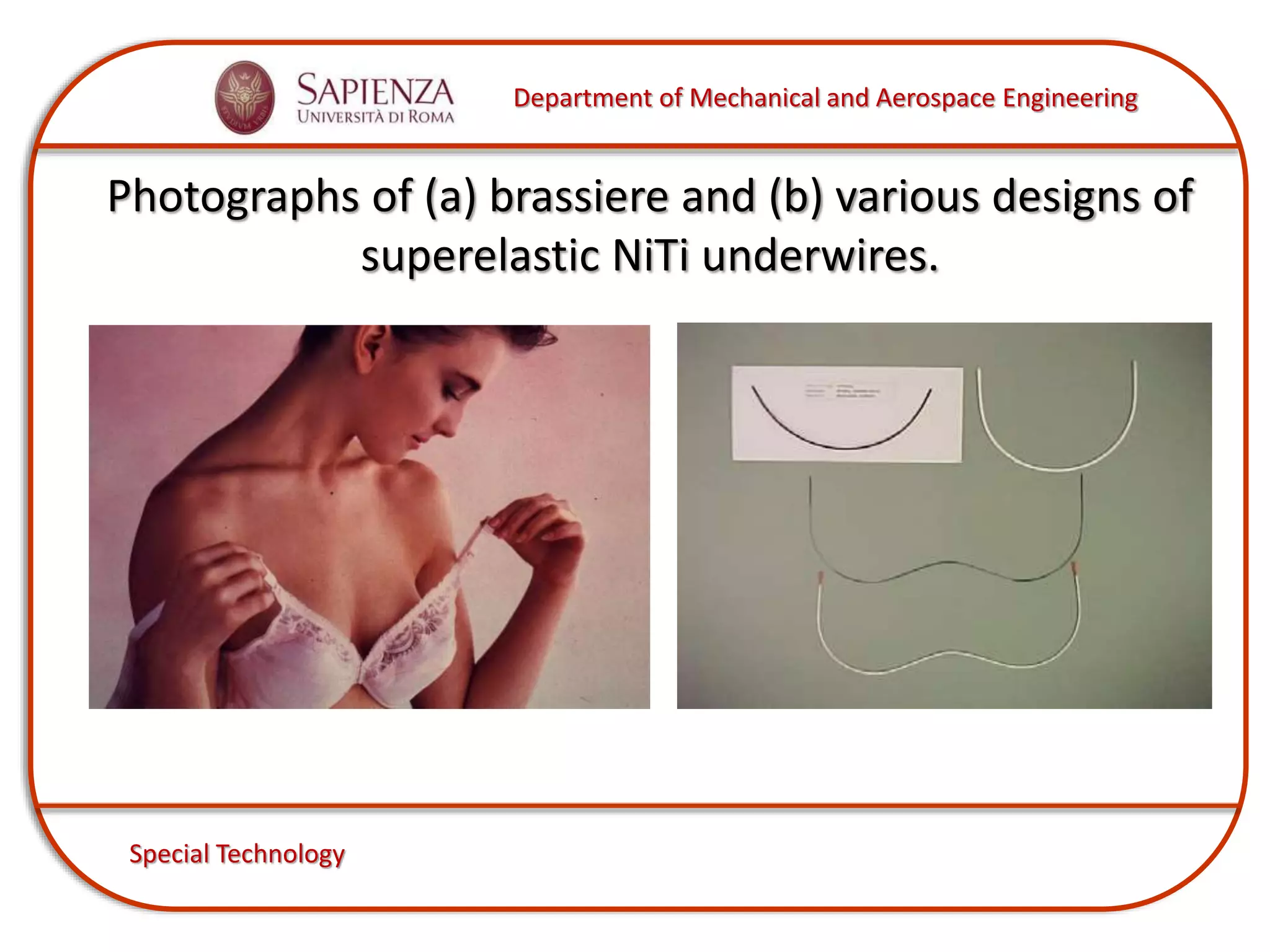

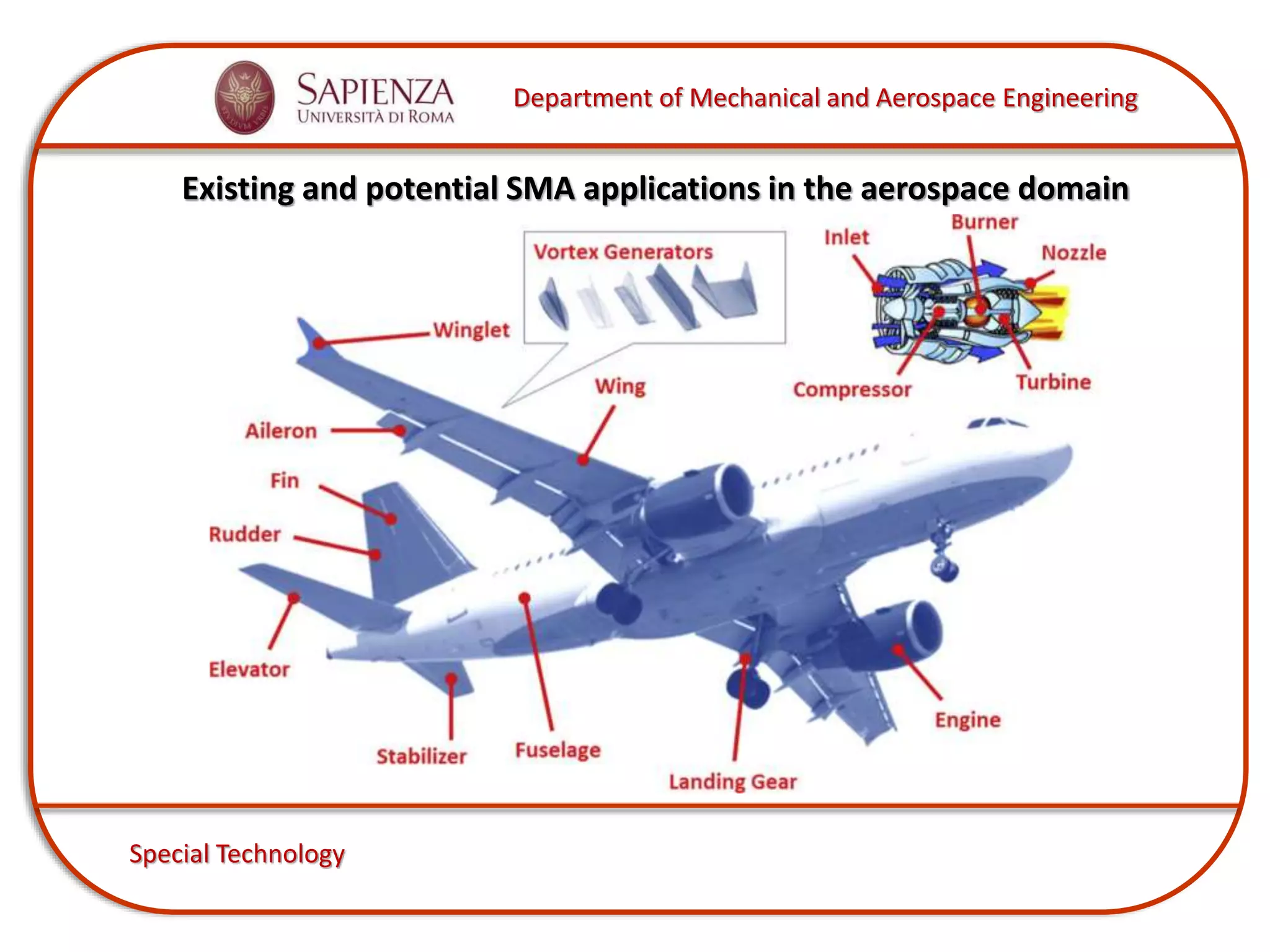

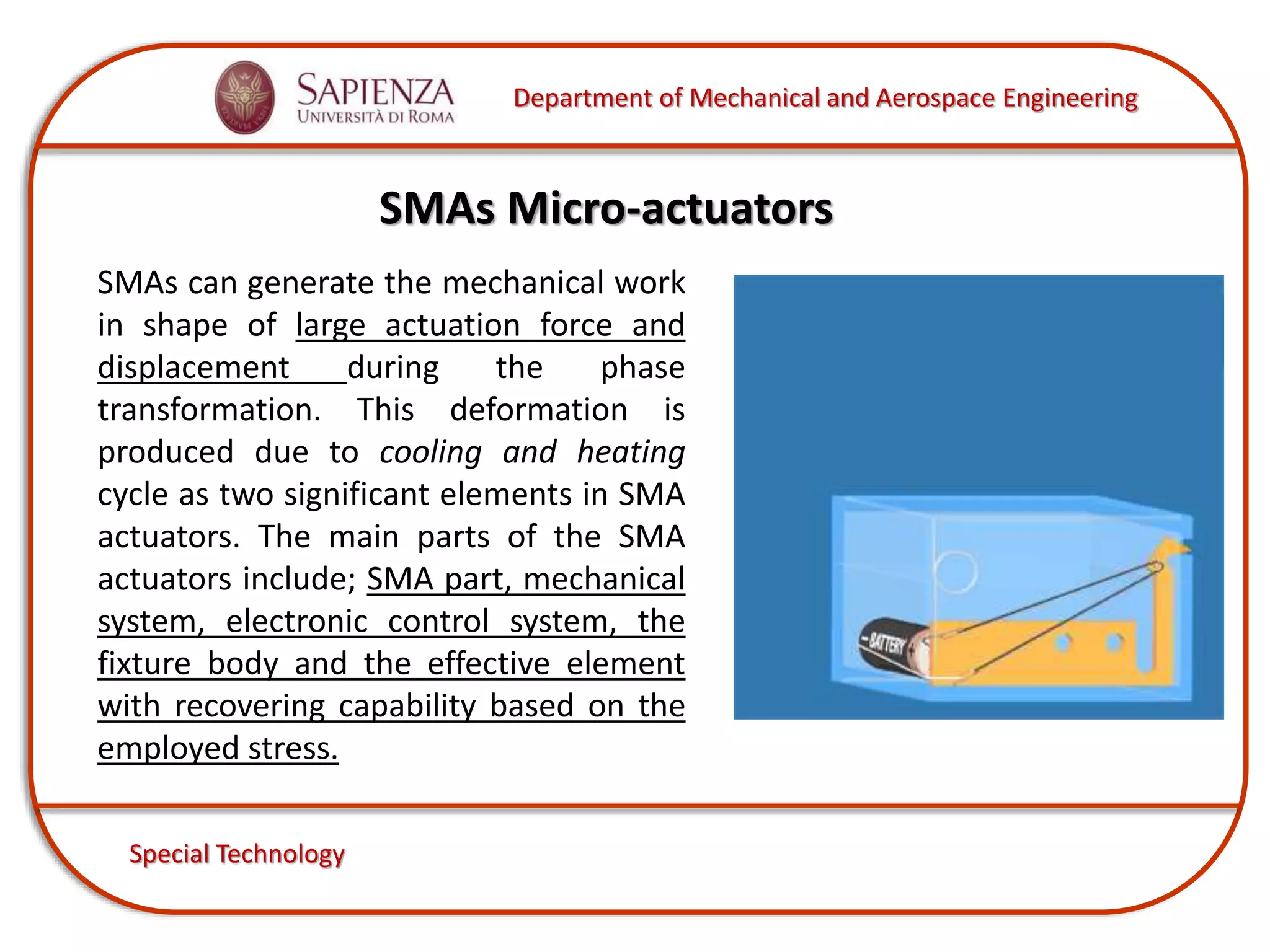

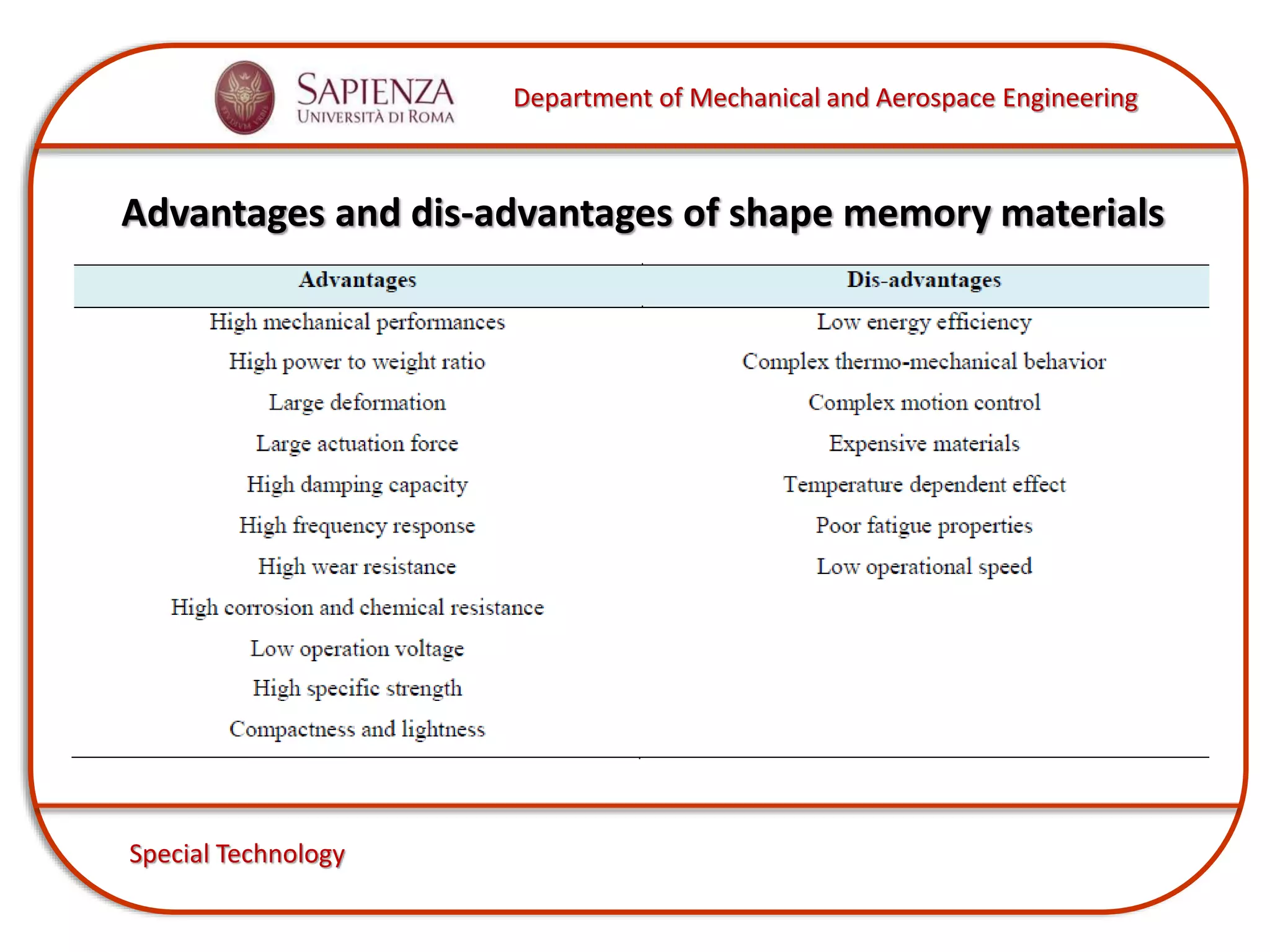

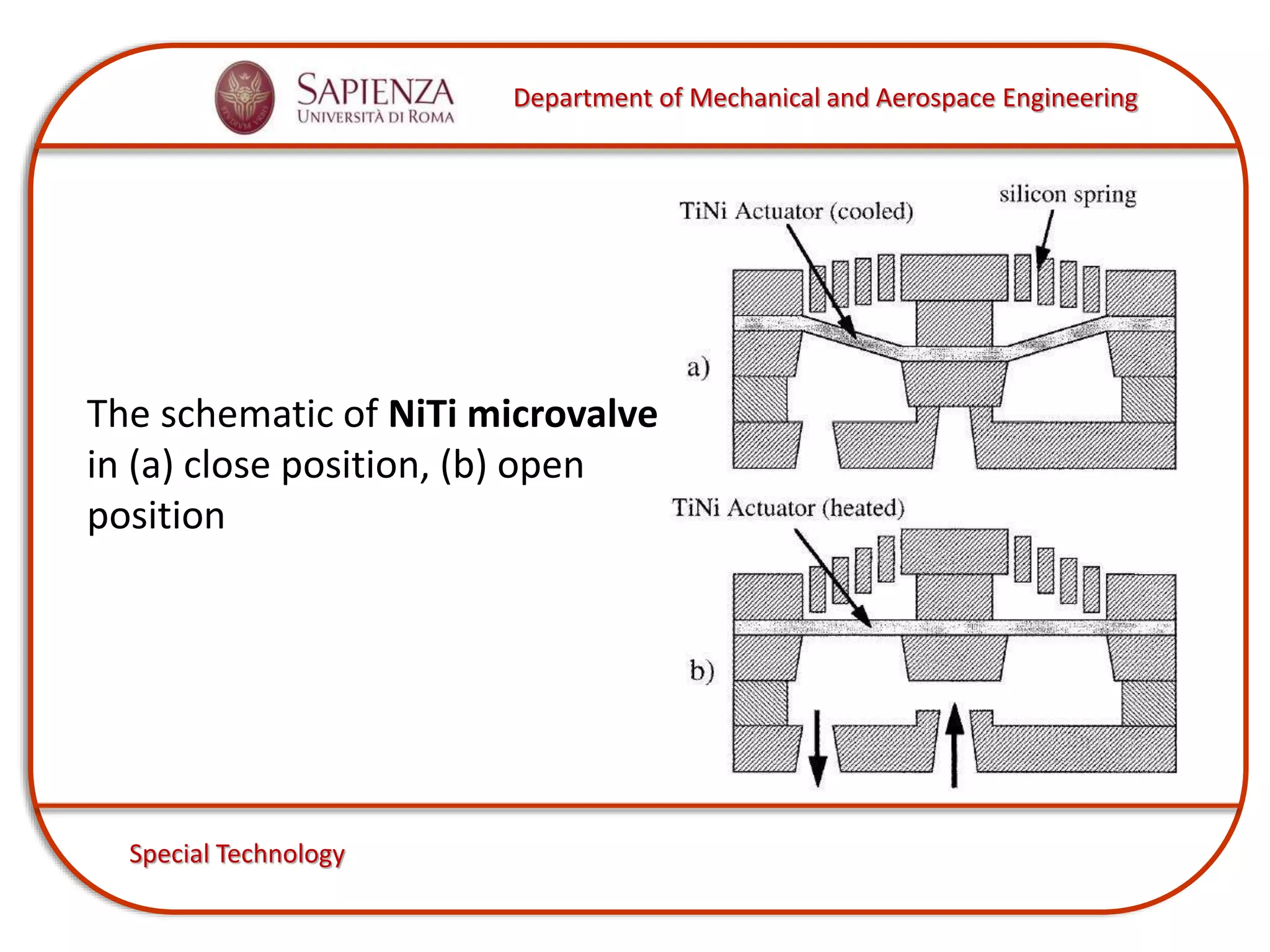

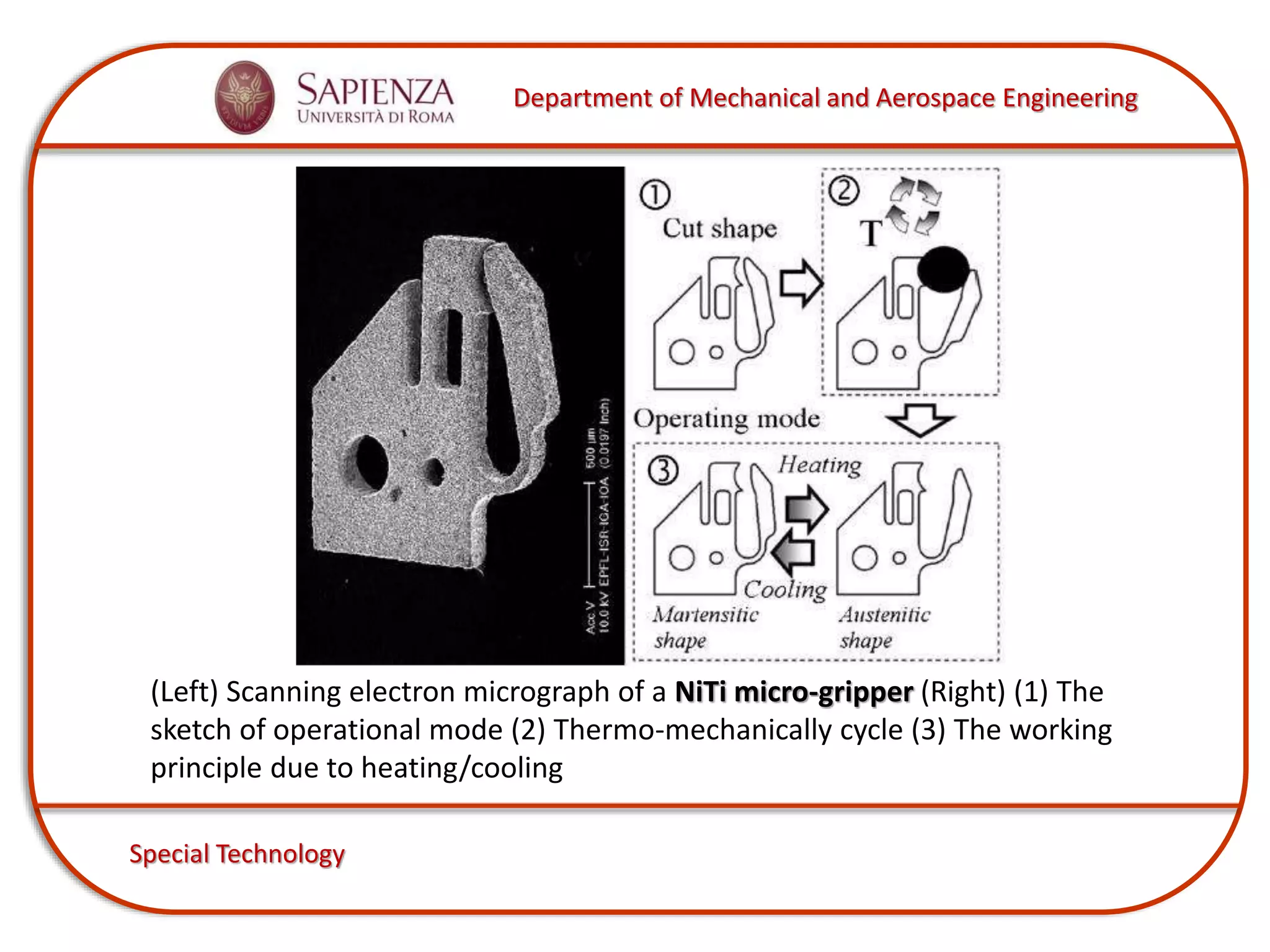

The document provides an overview of shape memory alloys (SMAs), highlighting their ability to undergo phase transformations which allow them to 'remember' their original shape upon heating or applying stress. It covers historical milestones, various types of SMAs, their mechanisms of action, applications in fields like medicine and aerospace, and the advantages and challenges associated with their use. Additionally, it illustrates specific applications such as stents in medical devices and micro-actuators in engineering.