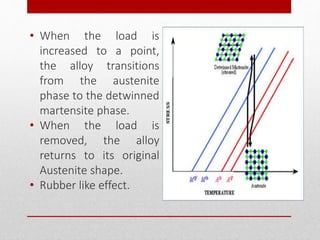

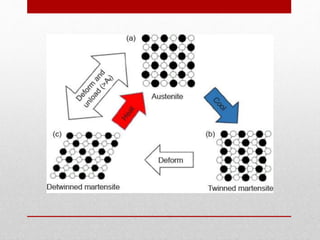

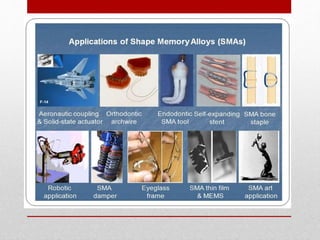

Shape memory alloys have two stable phases - austenite and martensite. In the martensite phase, the alloy can be deformed but will return to its original shape when heated above the transformation temperature due to a phase change back to austenite. This allows shape memory alloys to "remember" their original shape even after significant deformation. Common shape memory alloys include nickel-titanium (Nitinol) and copper-based alloys. Potential applications of these smart materials include use in automobiles, aerospace, biomedical devices, and civil infrastructure projects.