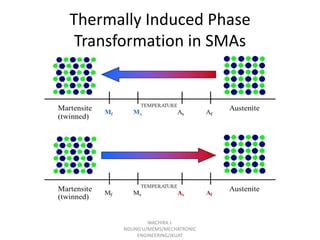

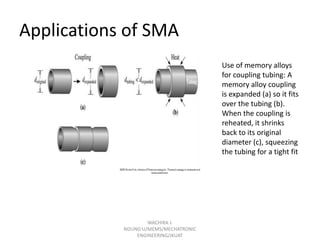

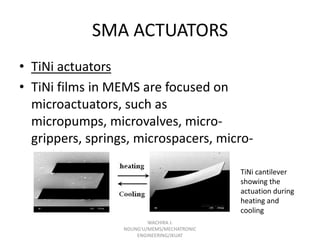

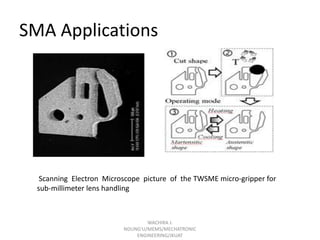

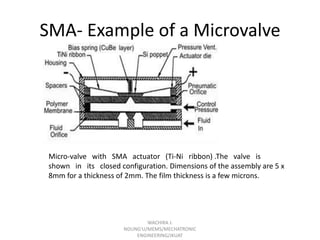

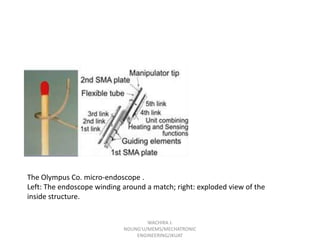

Shape memory alloys (SMAs) undergo a solid-to-solid phase transformation from martensite to austenite phases in response to temperature changes or stress, allowing large recoverable strains. SMAs such as nitinol exhibit one-way or two-way shape memory behavior and are used in applications like couplings, MEMS actuators and sensors, and microvalves. Common SMAs include nitinol, Cu-Zn-Al, and Cu-Al-Ni alloys.