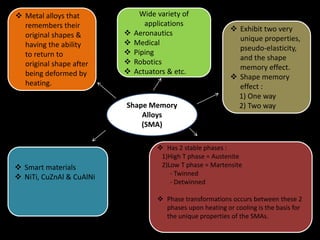

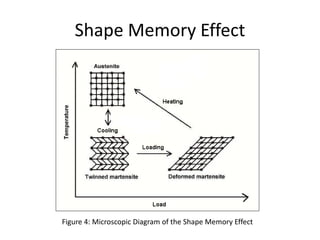

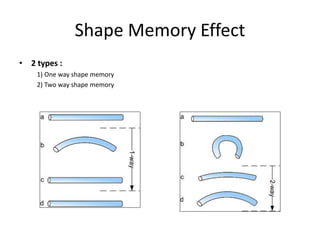

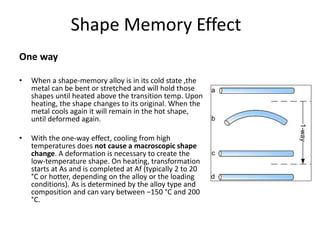

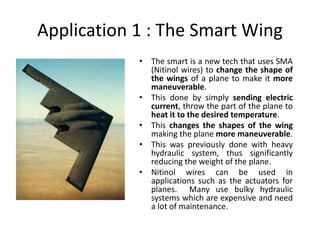

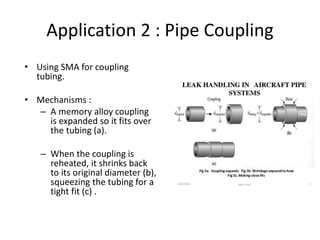

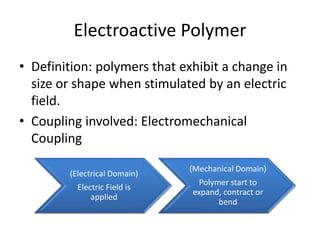

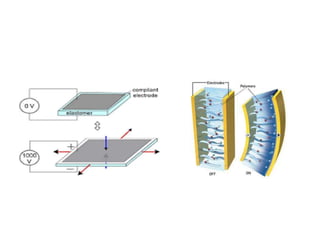

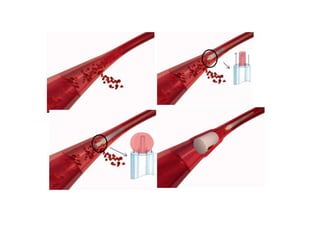

Shape memory alloys are metals that remember their original shape and can resume their shape after deformation by heating. They have two crystal phases, austenite and martensite, and the phase transformation between these upon heating or cooling allows the material to change shape. They have applications in areas like aeronautics, medicine, robotics, and more. Electroactive polymers are polymers that change shape or size when stimulated by an electric field through electromechanical coupling. Examples include dielectric elastomers used in artificial muscles and ionic gels used to stop bleeding in arteries. Both materials have advantages like lightweight actuators but also limitations like the dielectric strength of polymers.