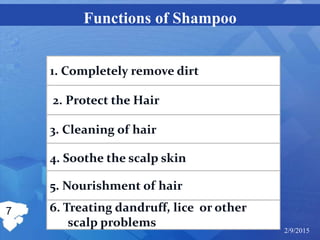

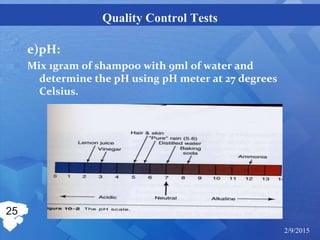

El documento describe el champú como un producto para el cuidado del cabello que elimina suciedad y contaminantes. Se detalla su composición, propiedades ideales, funciones y proceso de fabricación, así como pruebas de control de calidad. Además, se clasifican los champús según apariencia, uso y origen, y se explican los ingredientes clave como surfactantes y aditivos.