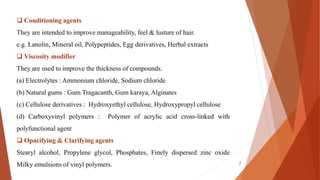

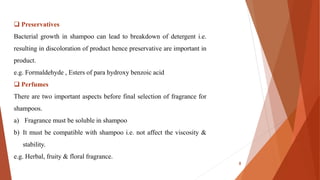

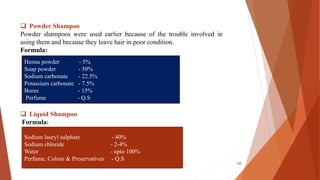

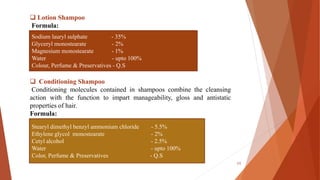

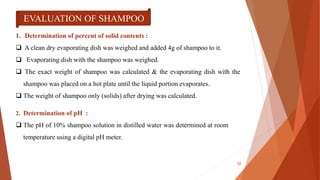

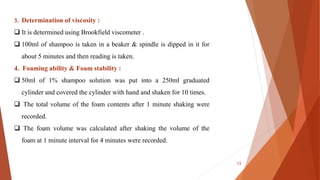

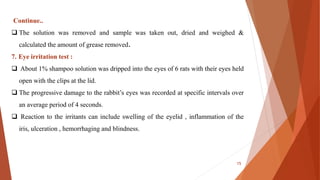

This document provides information on the key components of shampoos. It defines shampoo as a preparation containing surfactants that will remove dirt from hair without harm. The main ingredients include anionic surfactants, conditioning agents, thickeners, preservatives, and fragrances. Different types of shampoos are described such as liquid, lotion, and conditioning varieties. Guidelines for evaluating shampoos involve testing for solid content, pH, viscosity, foaming ability, skin/eye irritation, cleaning effectiveness, and packaging/labeling requirements.