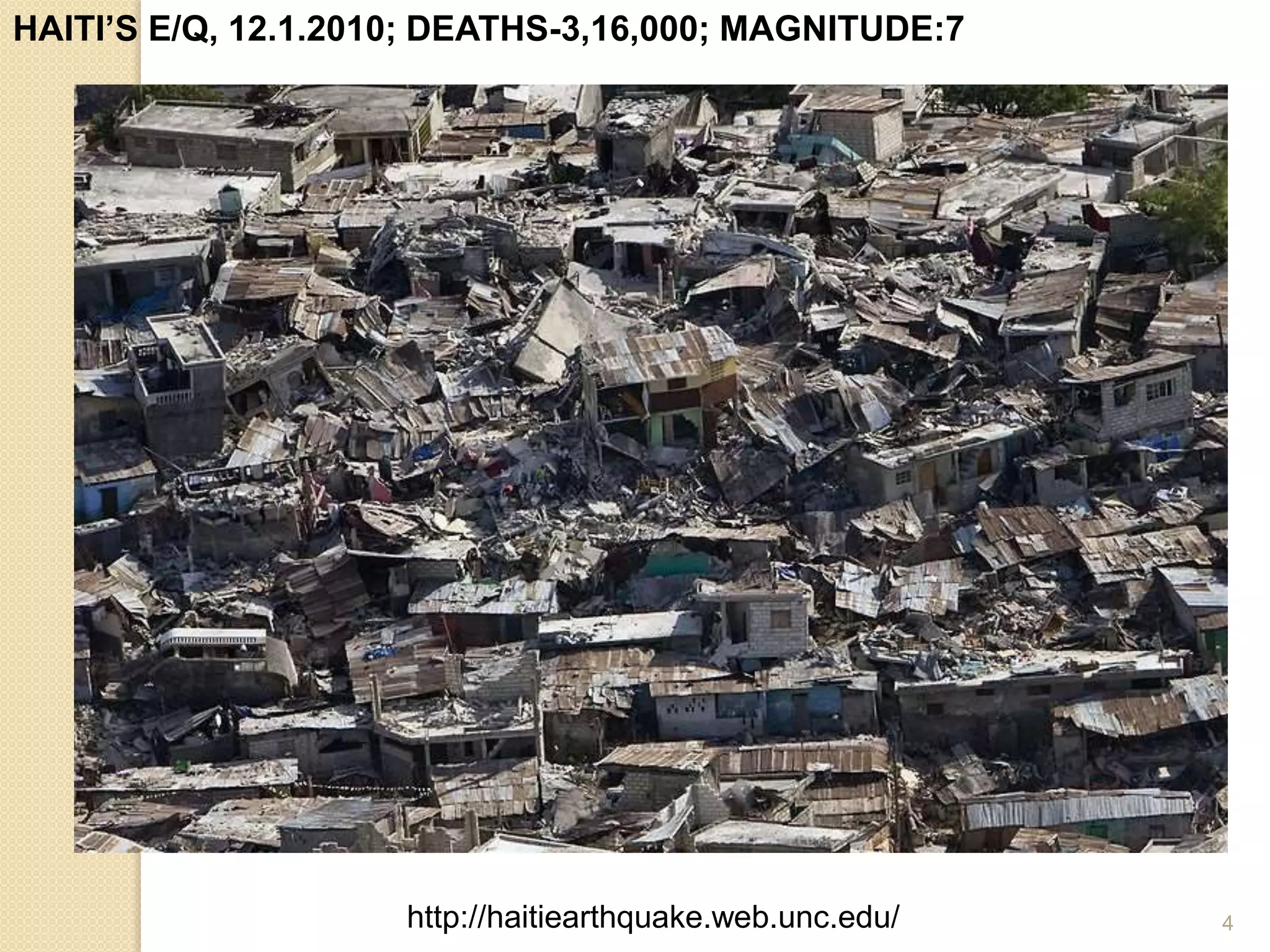

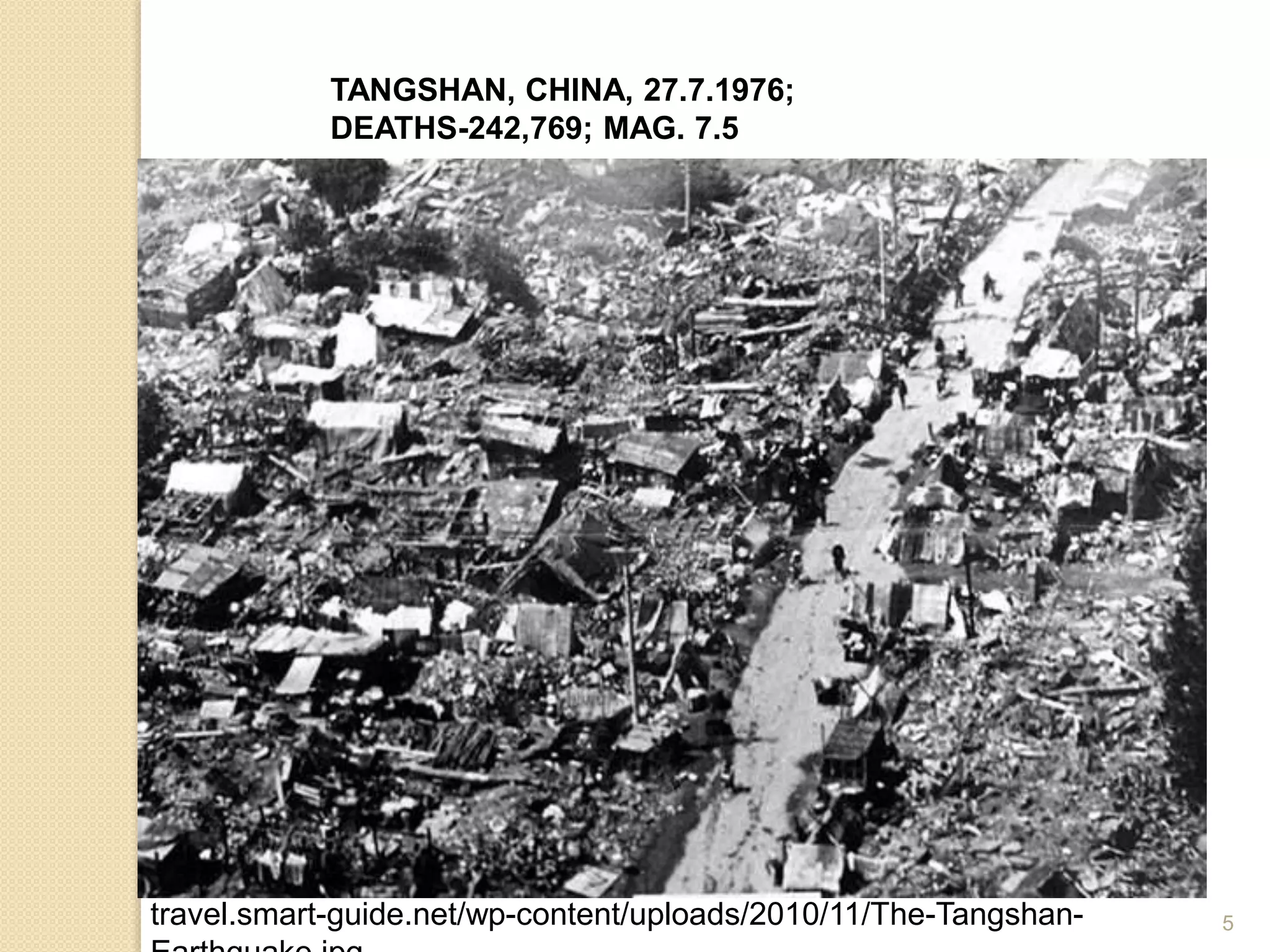

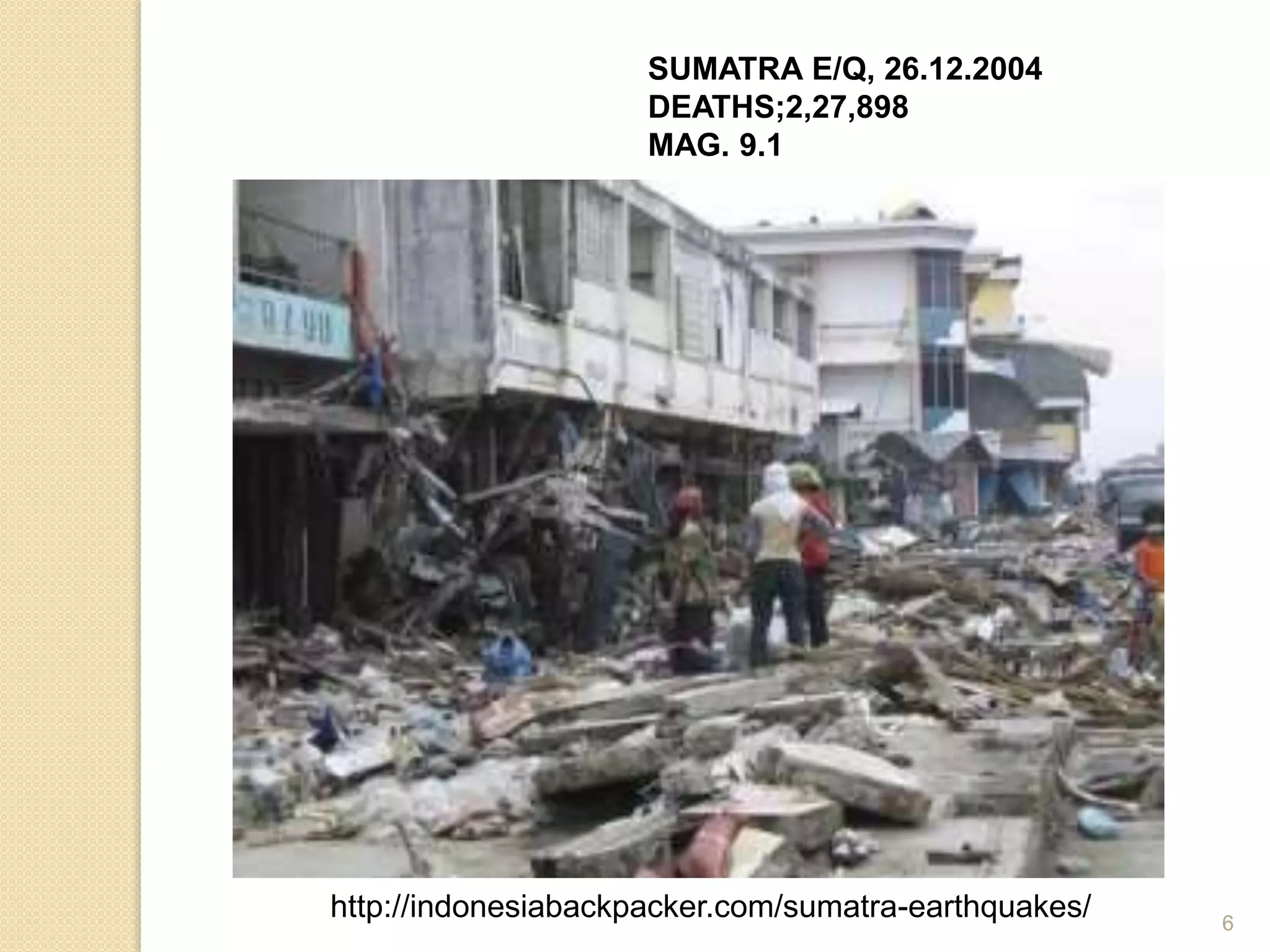

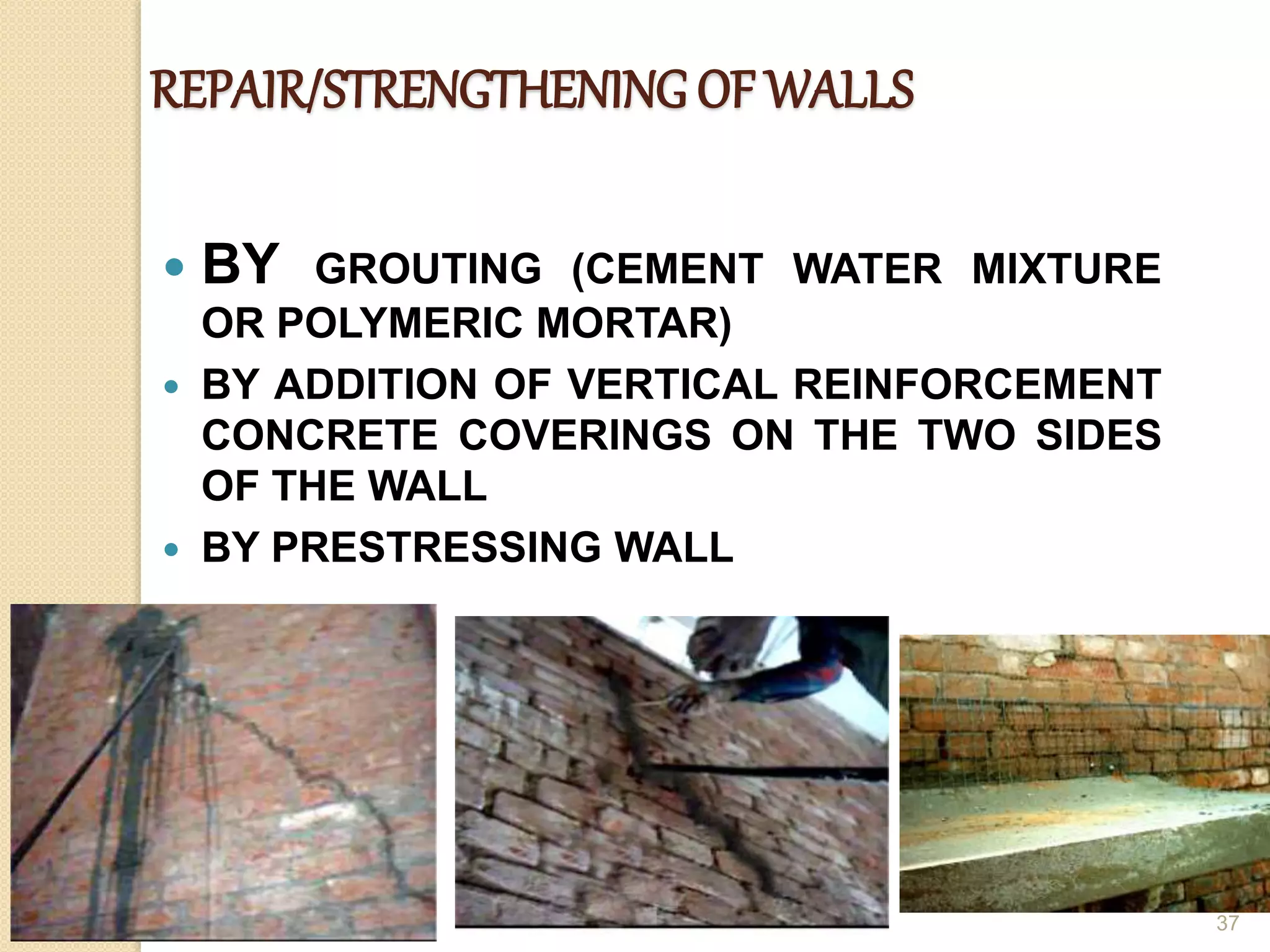

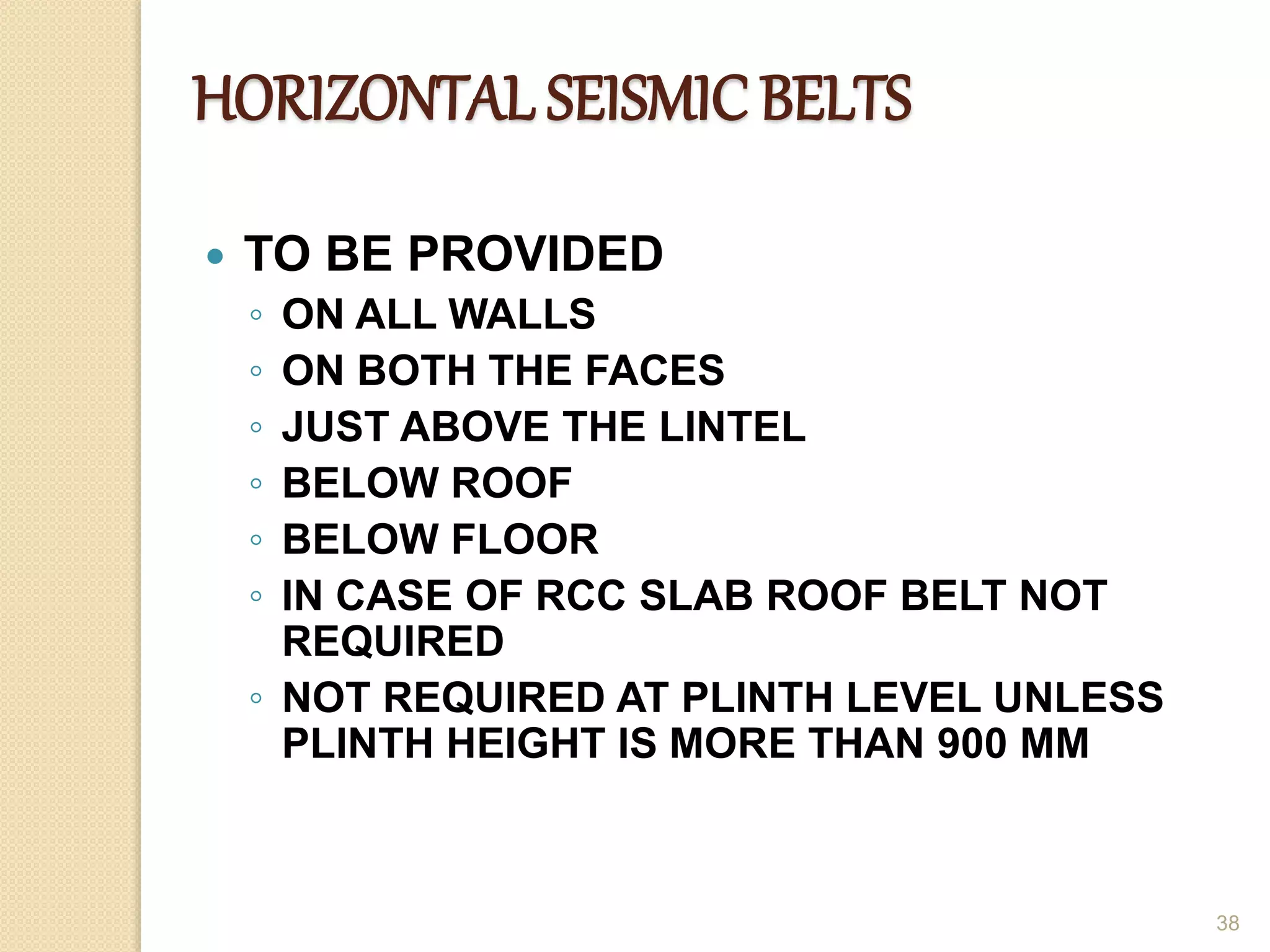

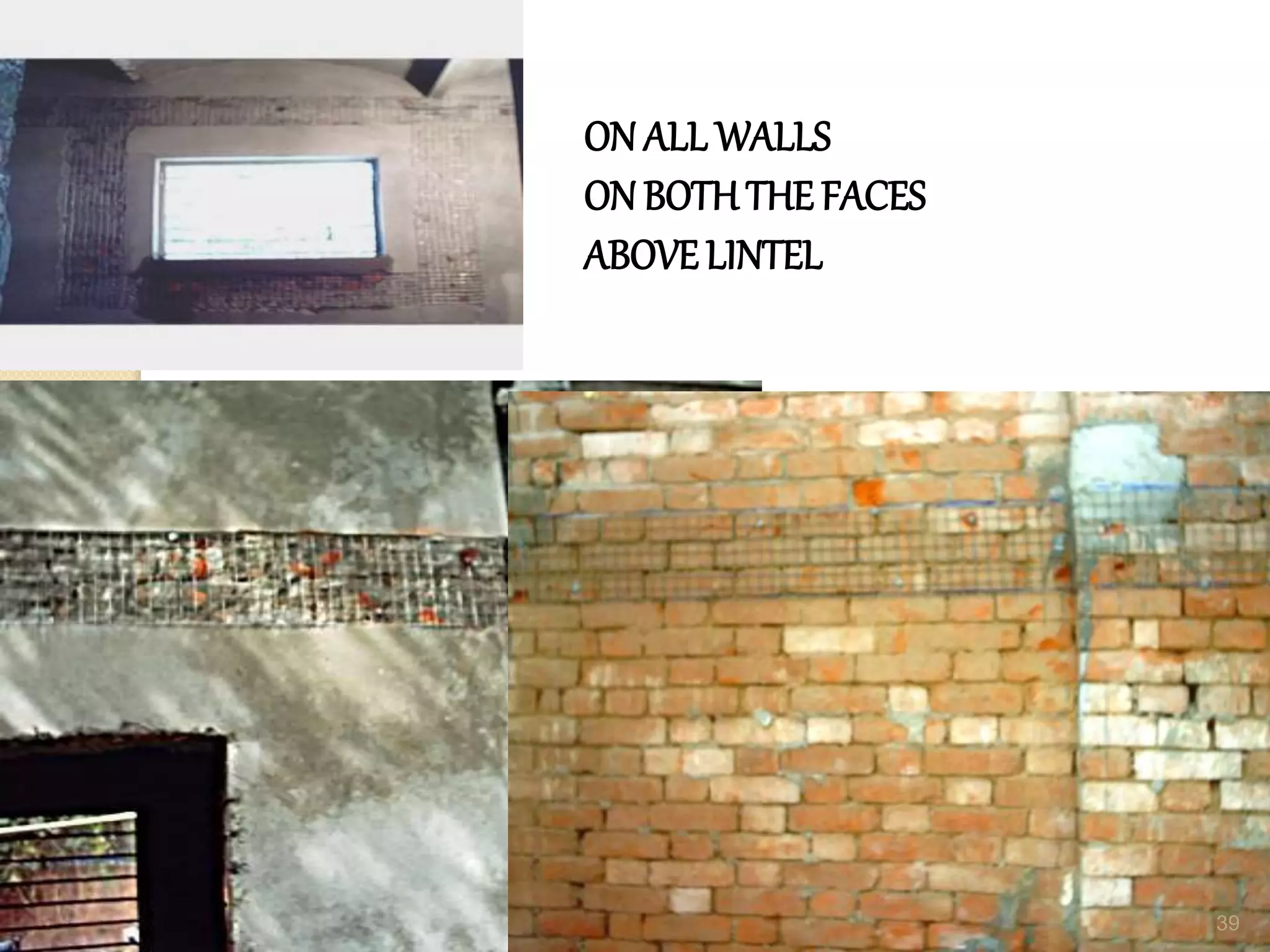

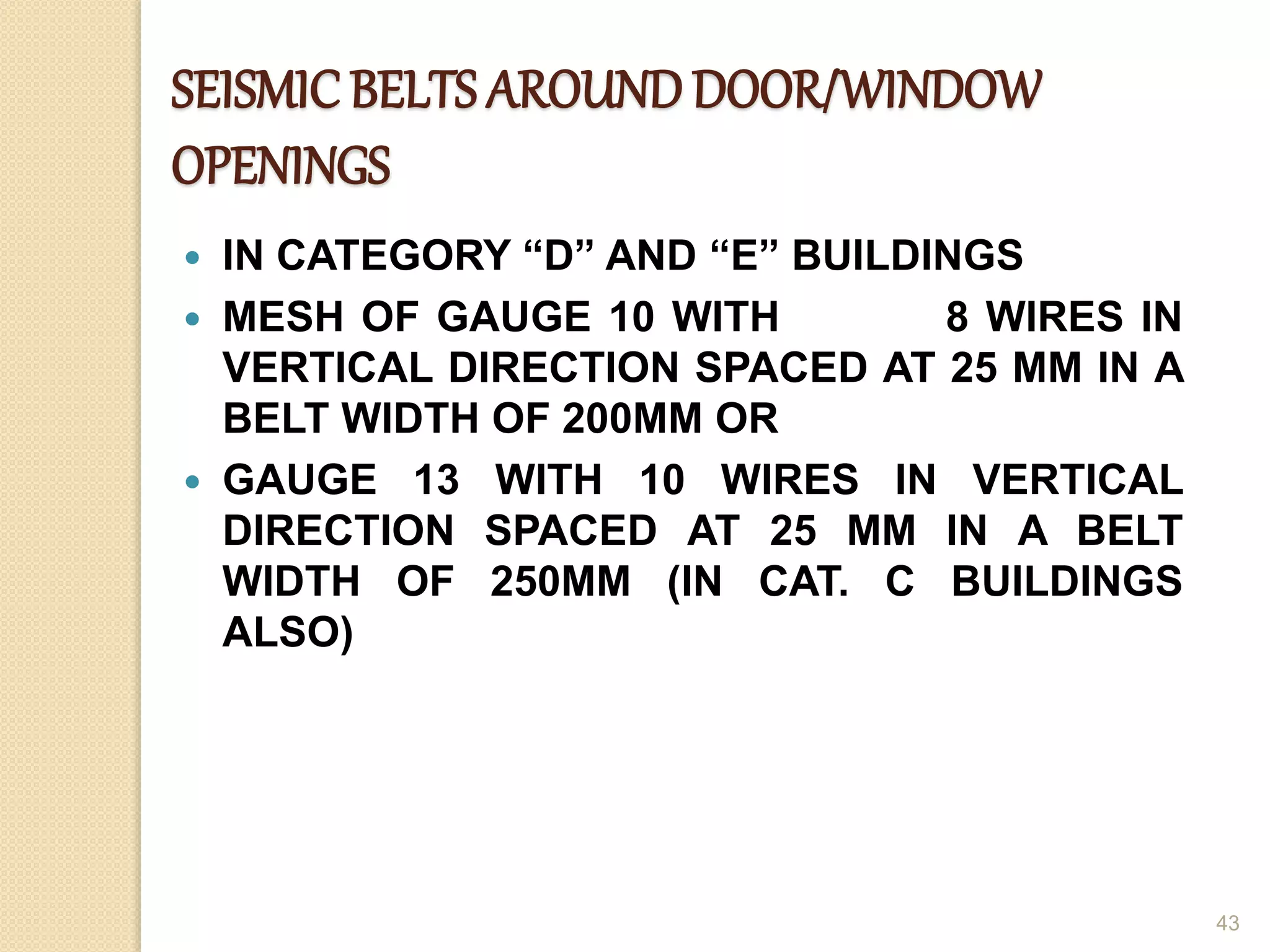

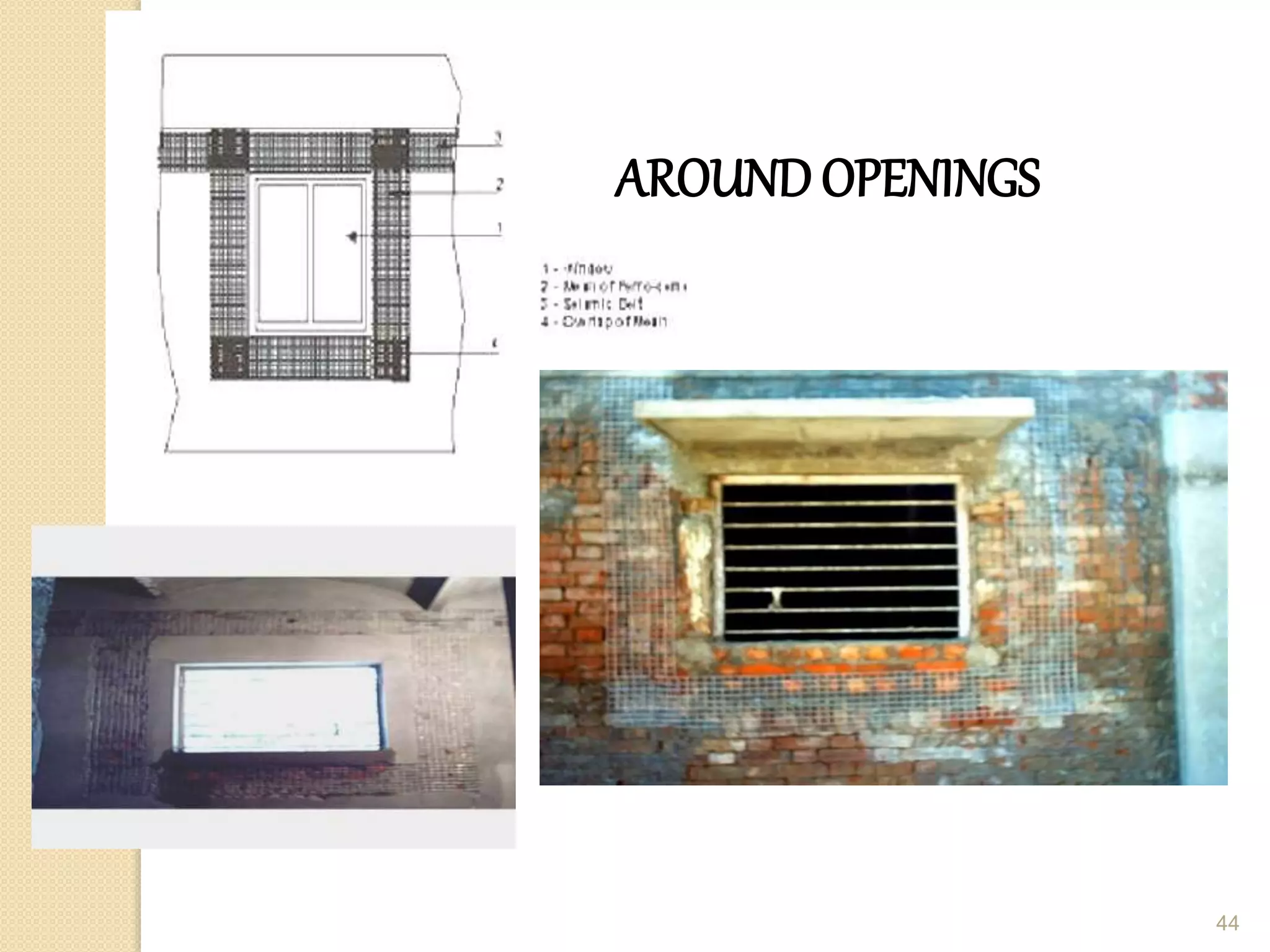

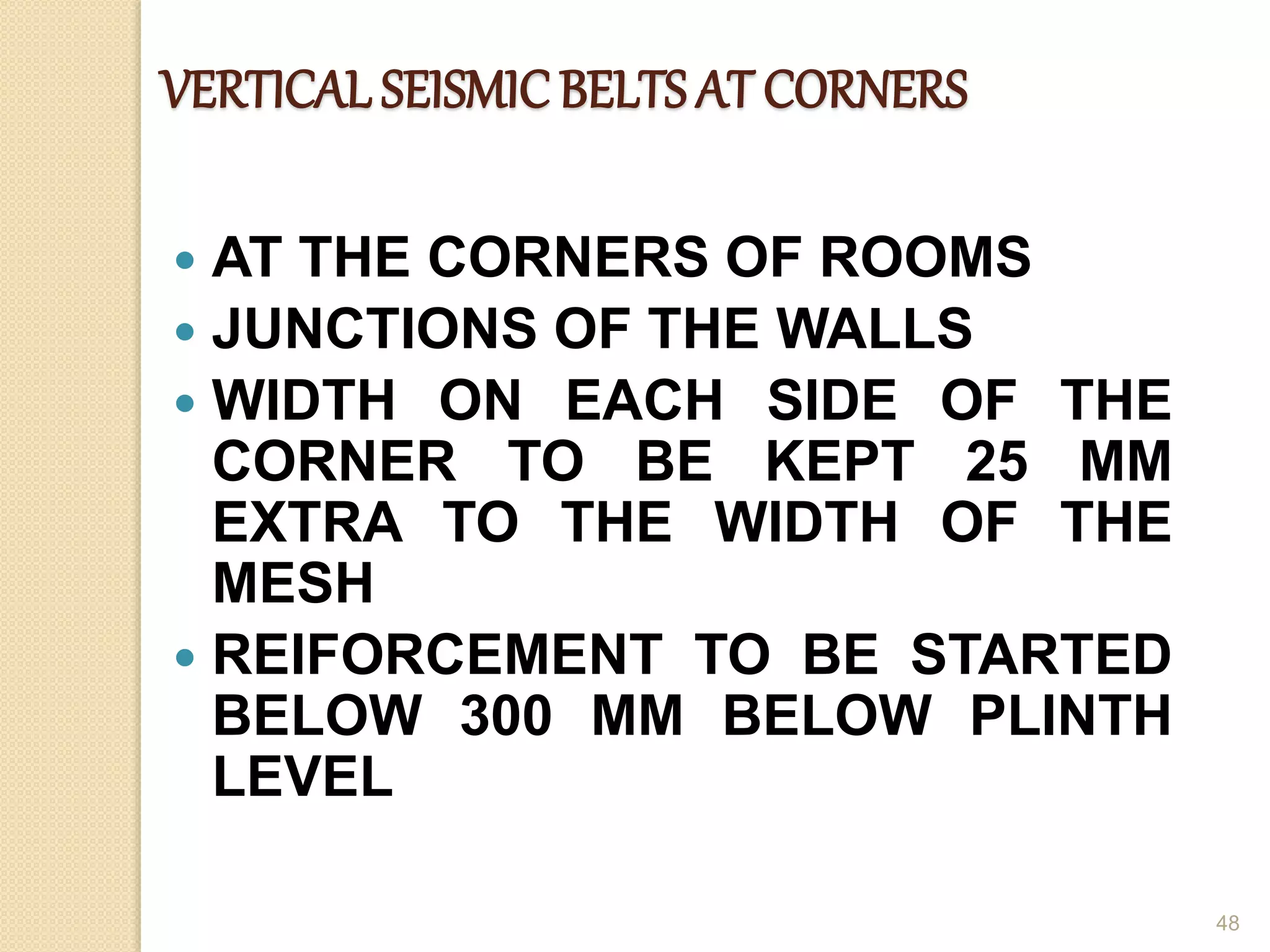

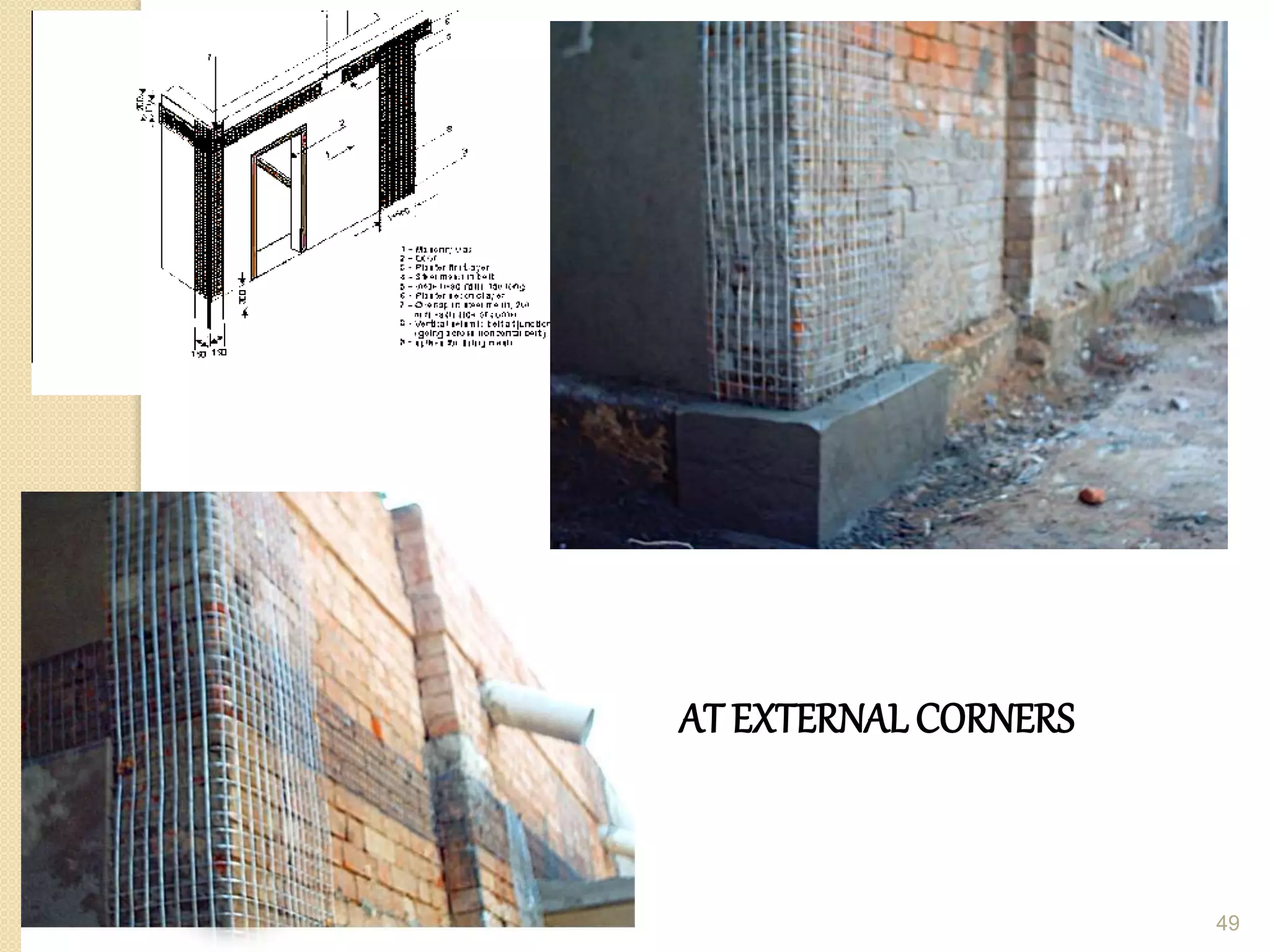

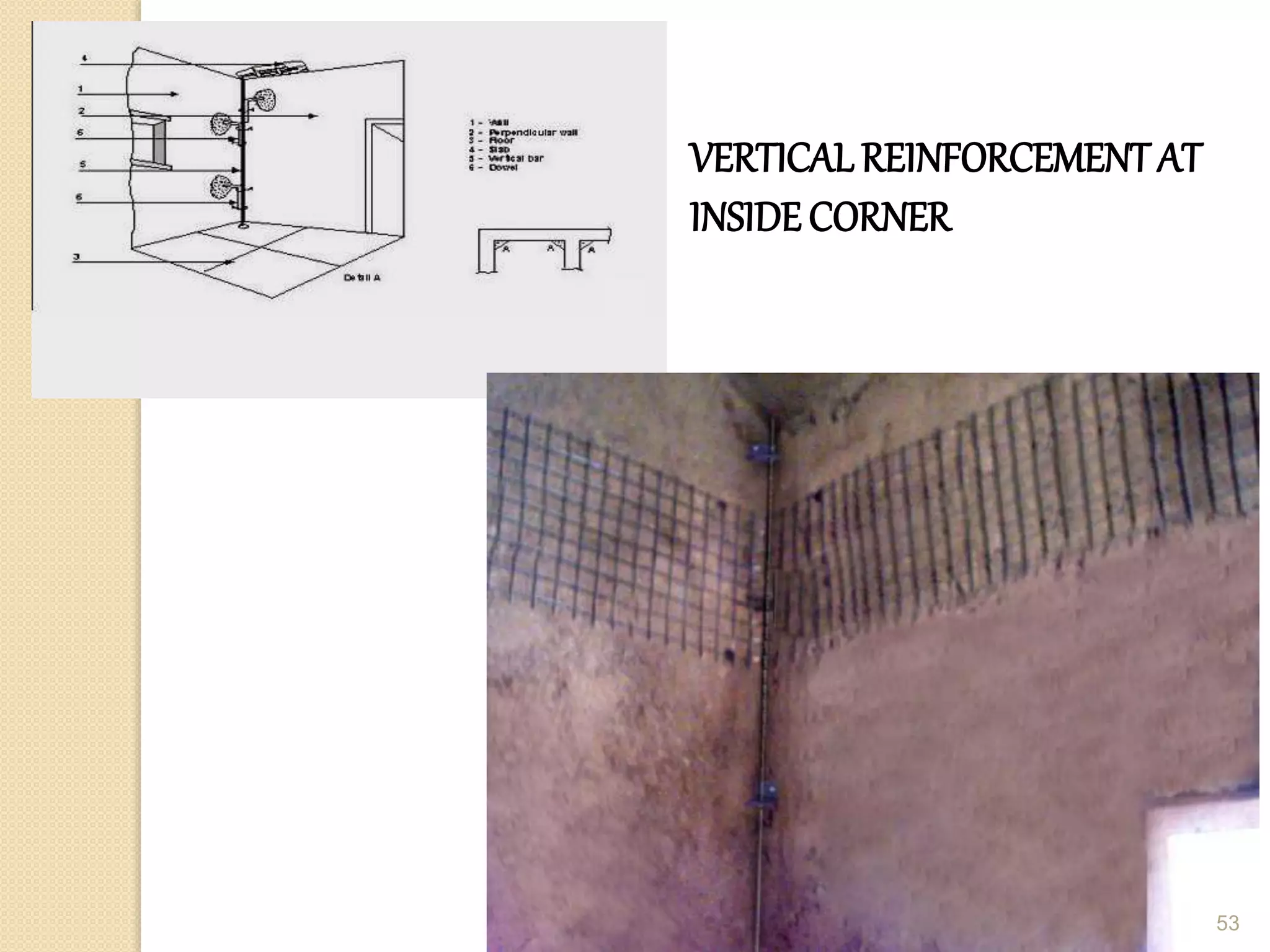

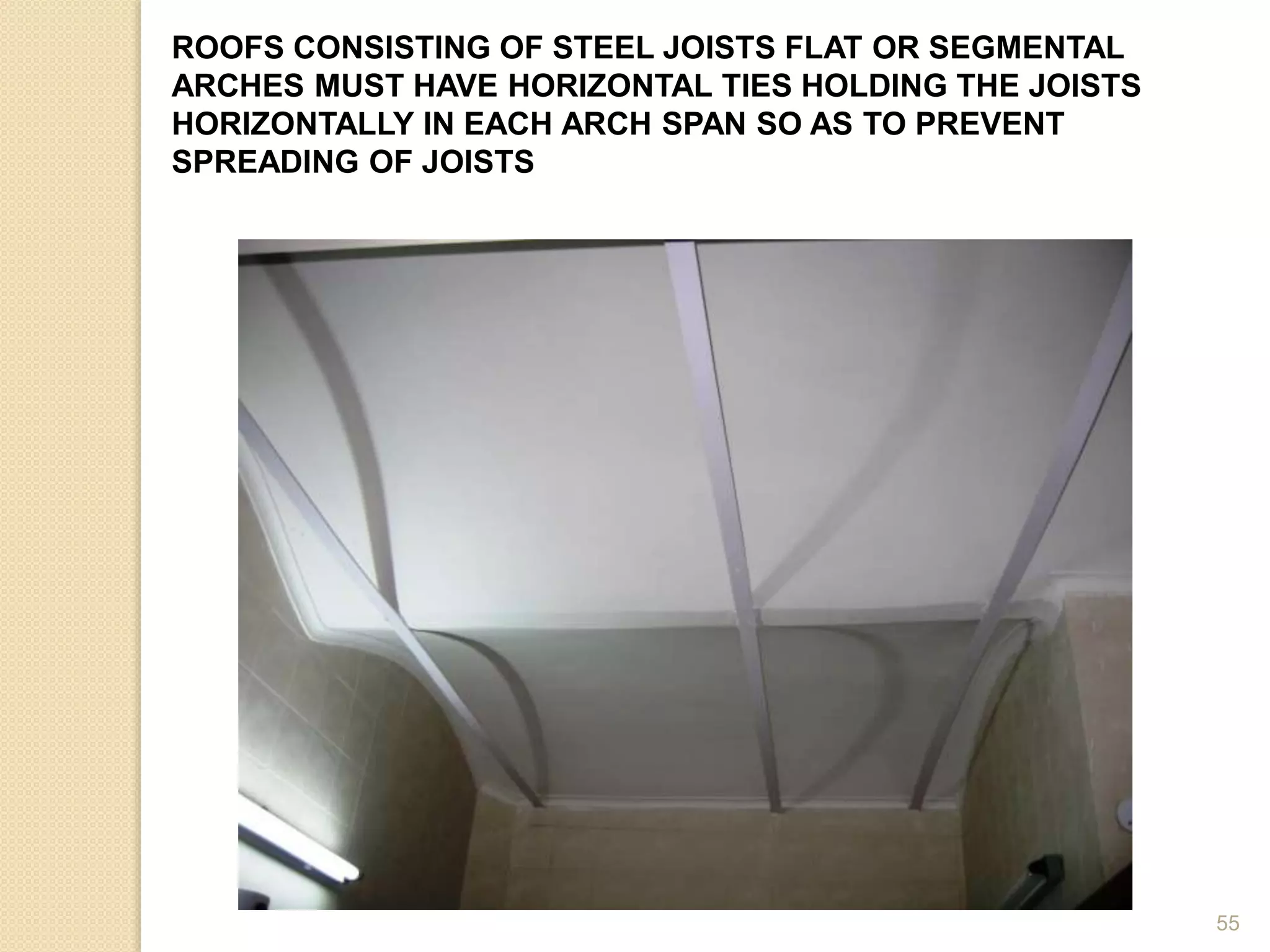

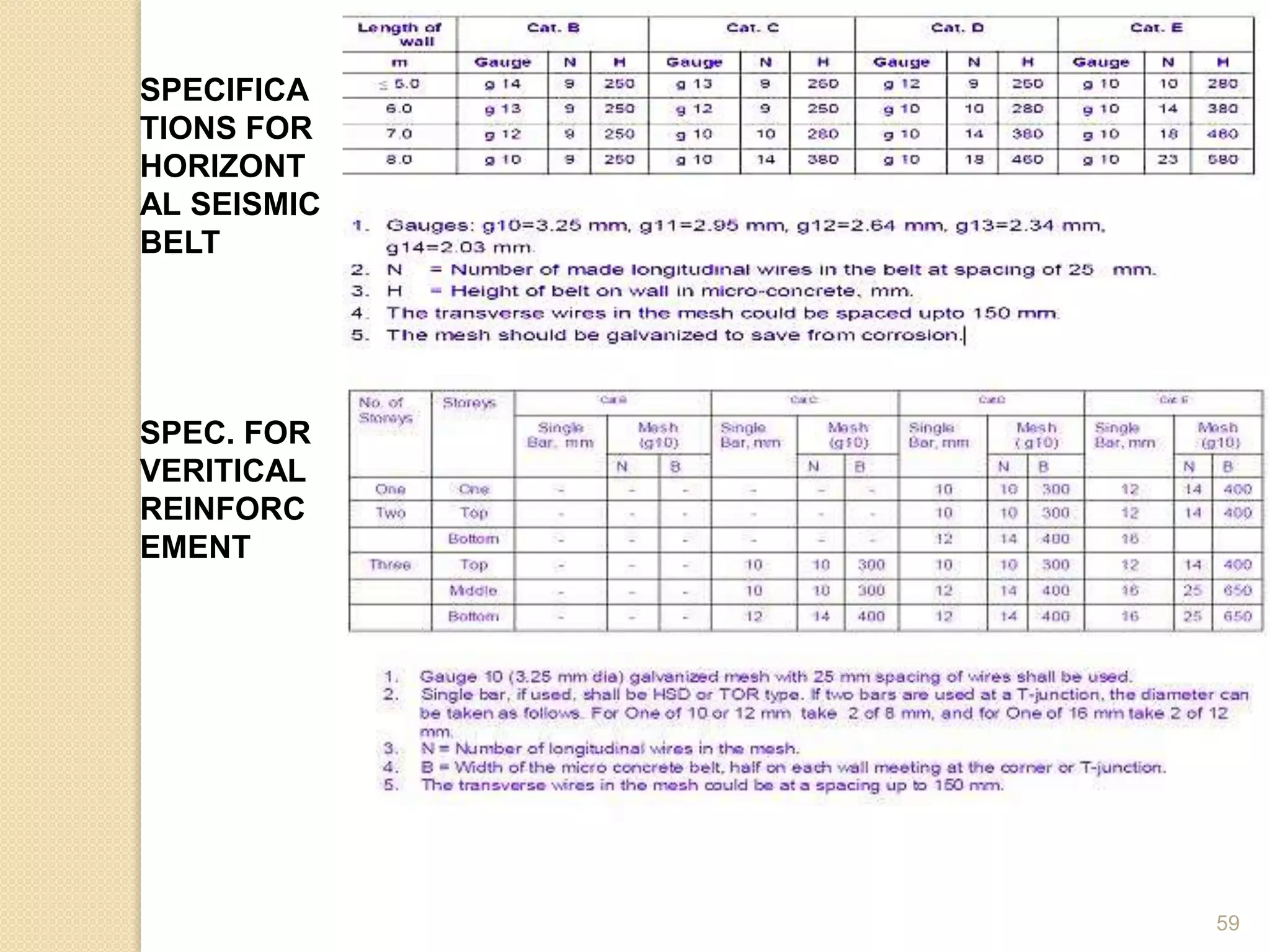

The document outlines the importance of rehabilitation and seismic retrofitting in buildings to mitigate the impact of earthquakes, which are increasingly destructive due to poor construction practices, particularly in developing countries. It discusses various causes of building failures and deterioration, methods for retrofitting and strengthening structures, and guidelines for the selection of materials and techniques. The need for adequate training and policy implementation for effective retrofitting practices is emphasized to improve earthquake resistance in existing buildings.