This document discusses prestressed concrete and provides details on:

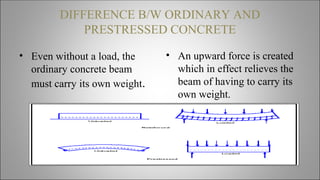

- The definition and principle of prestressing concrete by applying compression prior to external loads

- Common prestressing methods like hydraulic, mechanical, electrical, and chemical prestressing

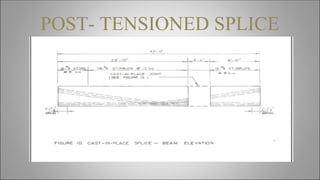

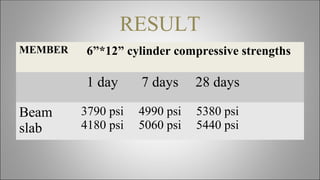

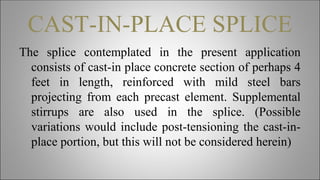

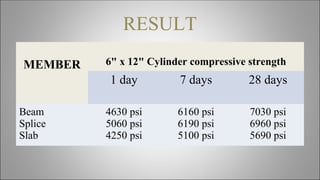

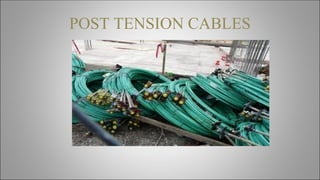

- Tests conducted on prestressed concrete components like post-tensioned splices and cast-in-place splices

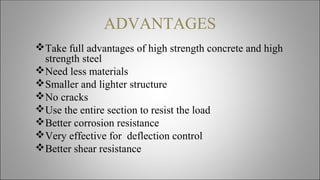

- Advantages of prestressed concrete like reduced materials and increased strength

- Applications in bridges, buildings, water tanks, and more

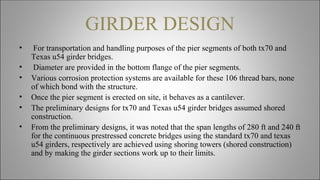

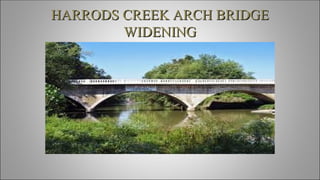

- A case study on widening the Harrods Creek Arch Bridge using prestressed concrete