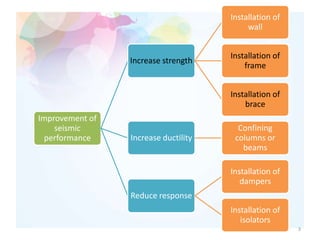

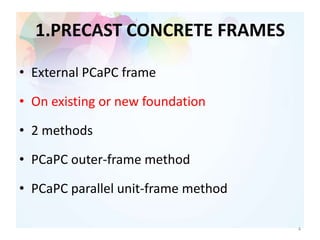

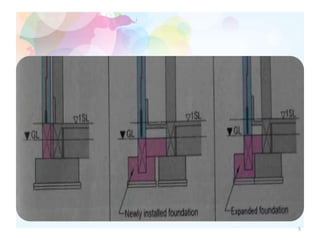

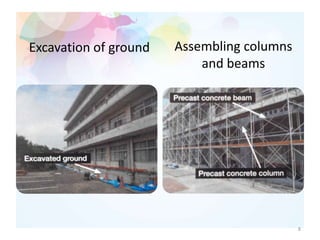

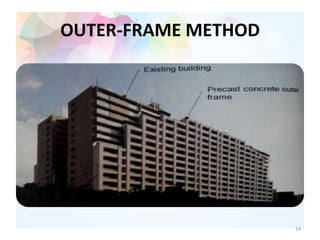

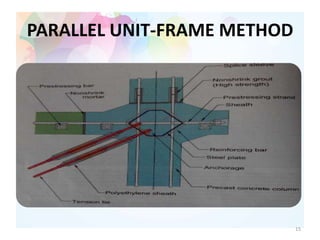

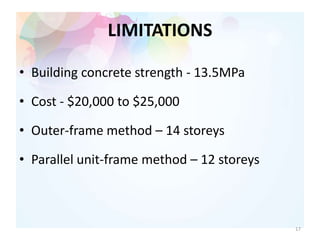

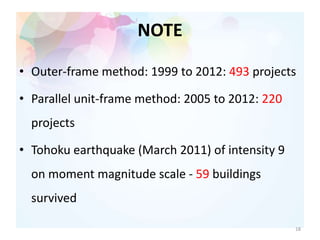

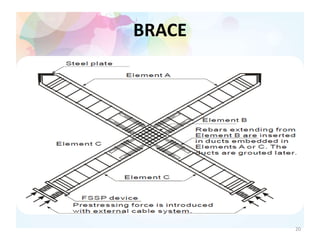

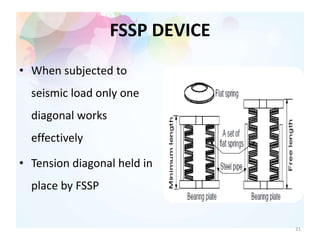

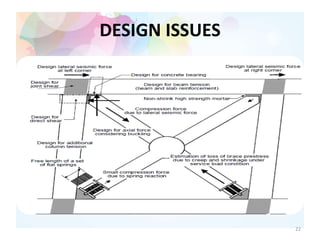

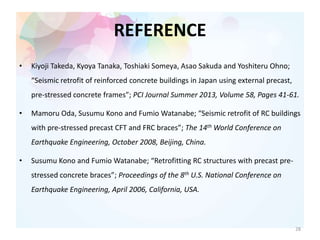

This document discusses methods for seismic retrofitting of existing buildings using precast concrete elements. There are three main methods - increasing lateral load capacity through the installation of precast concrete frames, braces, or armature cross walls. Precast concrete frames can be installed as an outer frame or parallel unit frames attached to new or existing foundations. Precast concrete braces are assembled off-site from precast leg and central units connected by pre-stressing cables. Armature cross walls involve replacing timber walls with precast wall panels connected by pins and light grouting.