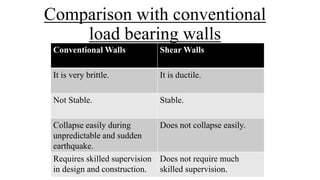

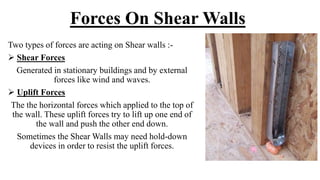

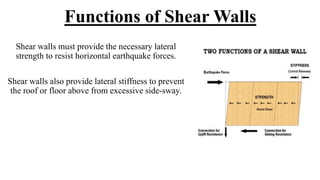

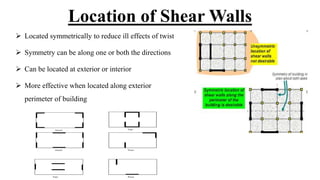

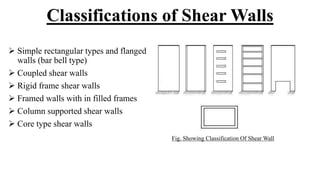

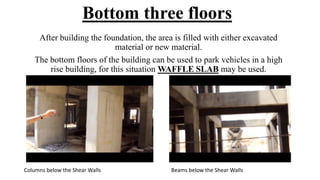

This document summarizes a seminar presentation on shear walls. Shear walls are vertical structural elements that resist lateral forces like winds and earthquakes. They distribute forces from floors, roofs, and exterior walls to the foundation. The presentation covers the purpose, types, construction process, advantages of shear walls, including how they are more stable and ductile than conventional walls. Shear walls are typically used in tall buildings and provide lateral strength and stiffness to resist horizontal seismic forces.